Device used for producing flat transposed aluminium conductor and provided with transposition device

A technology of transposition device and aluminum wire, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of large damage to film-insulated round aluminum wire, affecting the insulation strength of a single wire, and difficult operation for workers. To achieve the effect of safe and reliable performance, suitable for large-scale production, and remarkable application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

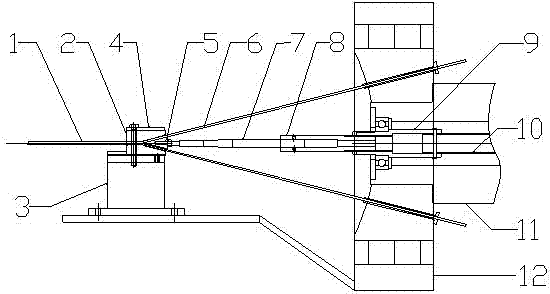

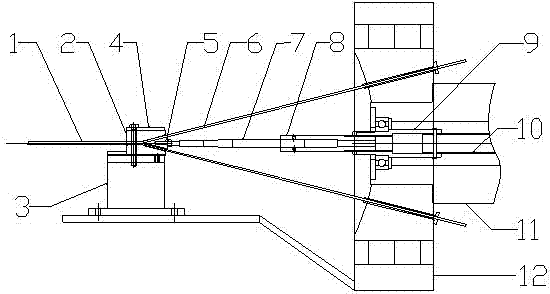

[0015] Such as figure 1 As shown, a device for producing flat transposed aluminum conductors with a transposition device, the device consists of two parts: the main body of the equipment and the transposition device;

[0016] The main body of the device includes a positioning shaft 7, an adjusting bushing 8, a connecting bushing 9, a fixed shaft 10, a twisting cage main shaft 11 and a twisting cage 12; A connecting shaft sleeve 9 is provided, and one end of the connecting shaft sleeve 9 is connected with the fixed shaft 10, so that the connecting shaft sleeve 9 remains in the center of the twisting cage main shaft 11 when the twisting cage 12 is running; one end of the connecting shaft sleeve 9 is connected with the adjustment shaft sleeve 8 wires buckle connection, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com