Connecting terminal capable of being installed and used conveniently

A terminal block, easy to install technology, applied in the direction of connection, conductive connection, electrical components, etc., can solve the problems of inconvenient use, affecting the electrical connection of electrical appliances, easy to rust, etc., to reduce production costs, improve wiring efficiency, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

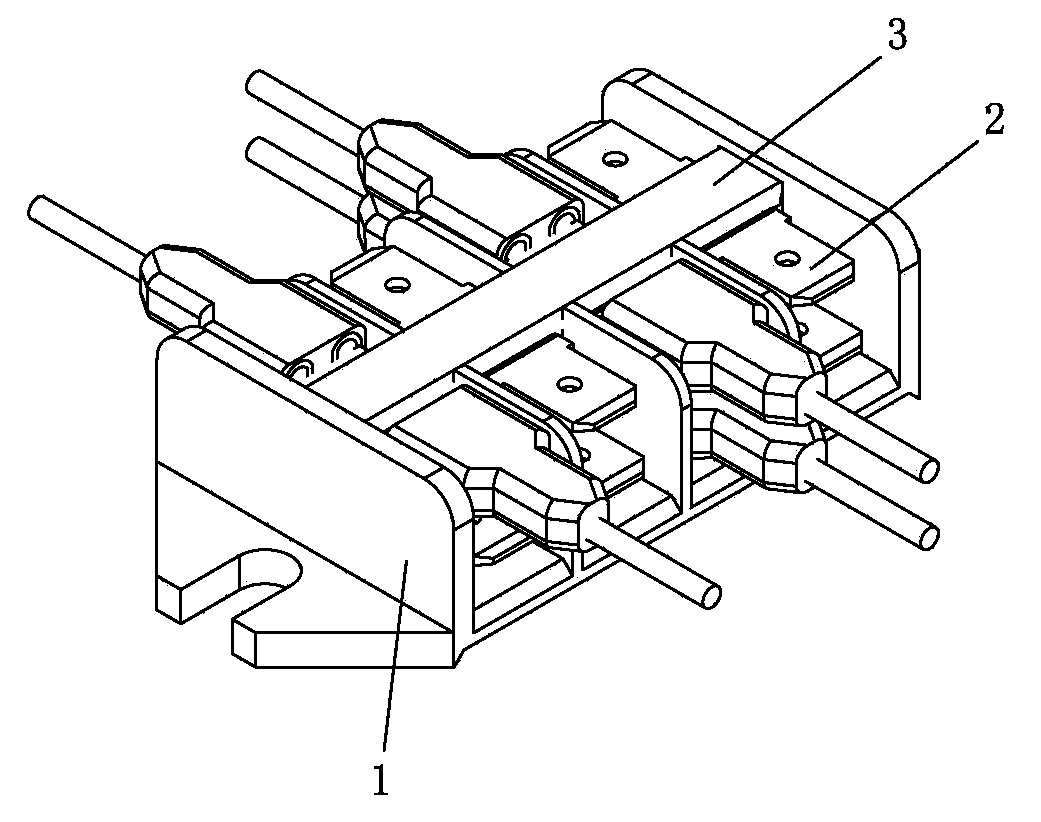

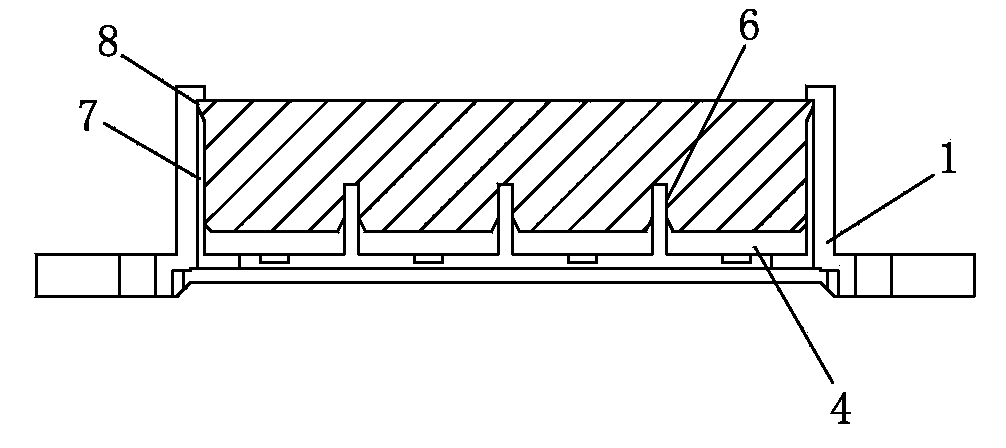

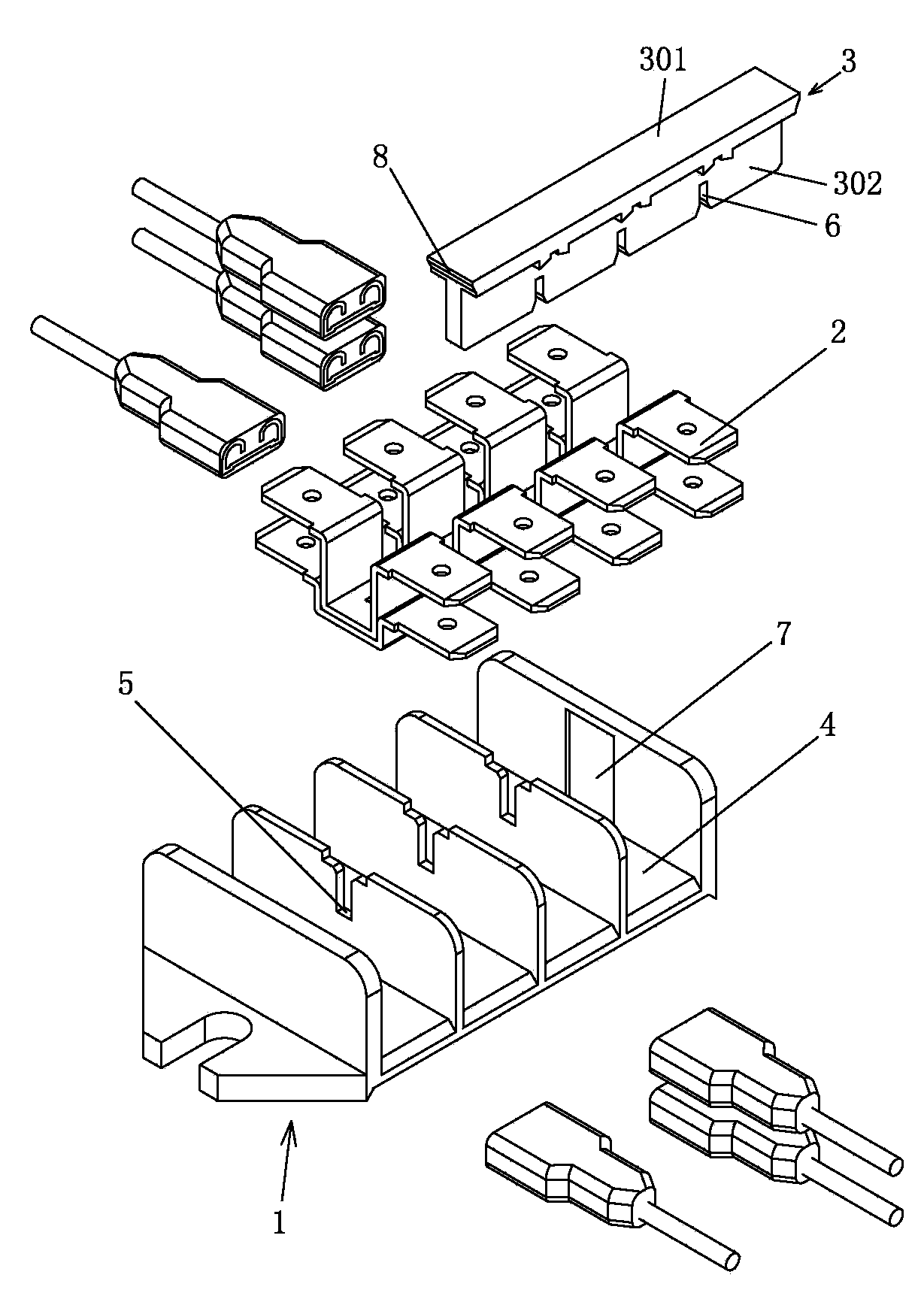

[0027] Embodiment one: if Figure 1 to Figure 6 As shown, a connection terminal that can be easily installed and used includes an insulating base 1 and a conductive terminal 2. The insulating base 1 is provided with a terminal groove 4, and a conductive terminal 2 is placed in the terminal groove 4. The insulating base 1 is also equipped with a pressing block 3, which is connected to the insulating base 1 in a detachable manner. The lower end of the pressing block 3 is against the conductive terminal 2 to limit the position of the conductive terminal 2, so that the conductive terminal 2 is not easy to loosen.

[0028] The pressure block 3 is an independent horizontal pressure plate, and the horizontal pressure plate is fixed on the insulating base 1; the top of the side wall of the terminal groove 4 has a snap-in opening 5, and the lower part of the pressure block 3 has a corresponding positioning gap 6 , the positioning notch 6 on the lower part of the pressing block 3 is eng...

Embodiment 2

[0033] Embodiment two: if Figure 7 As shown, this implementation is similar to Example 1, the only difference is that in order to meet the installation needs of users, the manufacturer sets corresponding installation holes 9 on the pressing block 3, so that when the terminal is in use (installed on the electrical product) ) can be fixed with external connections.

Embodiment 3

[0034]Embodiment 3: The pressing block 3 can be an independent horizontal pressing plate, and the horizontal pressing plate is connected to the insulating base 1 through a screw assembly, which will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com