Method for obtaining mechanical joint stiffness

A joint and stiffness technology, applied in the field of obtaining the stiffness of mechanical joints, can solve problems such as inaccurate stiffness performance analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

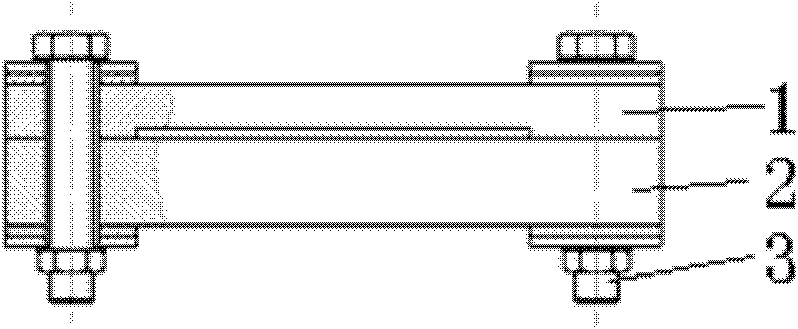

[0042] figure 1 It is a schematic diagram of the structure of the experimental object, in which the size of the upper plate 1 is 300mm×400mm×25mm, and the density of the upper plate 1 is 8100Kg / m 3 , the modulus of elasticity is 2.07×10 11 Pa, Poisson's ratio is 0.28. The size of the lower plate 2 is 300mm×400mm×40mm, and the density of the lower plate 2 is 6980Kg / m 3 , the modulus of elasticity is 1.01×10 11Pa, Poisson's ratio is 0.245. The contact force between the two plates is applied by four identical bolts 3 . Rubber, spacers and thrust bearings are padded between the bolt 3 and the two plates. The contact stiffness between the two plates is much larger than that of the rubber, so that the joint of the guide rail can be isolated. The data measured in the experiment are only for the joint surface where the upper and lower plates are pressed against each other. The average surface pressure loaded between the upper and lower plates is 0.06 MPa. The experimental device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com