Device and method for carrying out filling mining plane strain simulation test

A simulation test and plane strain technology, applied to teaching models, educational tools, instruments, etc., can solve the problems of calculation and evaluation of the pushing force of the filling support when the filling is not compact, the reliability of the test results cannot be guaranteed, and there are many difficulties in the movement of overlying rocks, etc. problem, to achieve the effect of high practical value, stable and reliable method, and prevent scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

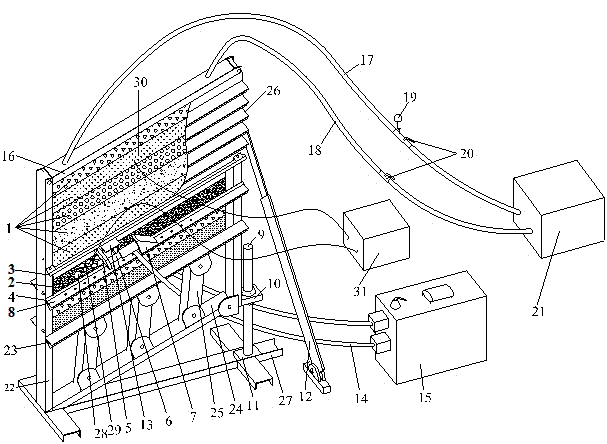

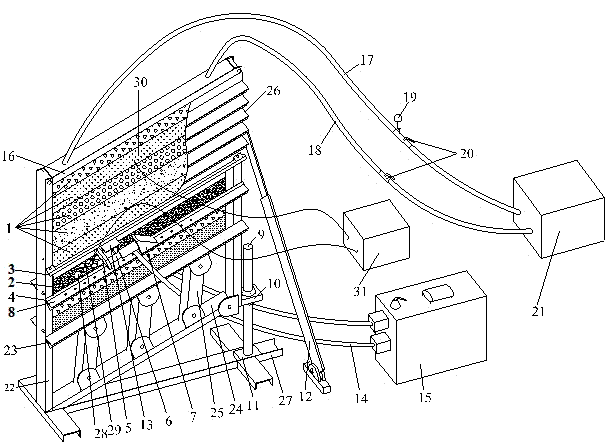

[0021] figure 1 As shown, the plane strain simulation test device for filling mining of the present invention is mainly composed of a test model frame filled with simulated coal formation 1, a simulation filling mining simulation system, an equivalent loading system and an information collection system; the simulation filling mining simulation system is located at At the simulation coal seam place of the test model frame, the equivalent loading system is located on the top of the test model frame, and the simulation filling and mining simulation system is connected with the information collection system; The guard plate 26 is formed, wherein the stand 22 includes a bottom groove seat 27, a lower supporting plate 24 that opens and closes at an angle with the bottom groove seat 27, and the opening and closing angle between the bottom groove seat 27 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com