Inclined bell jar type oil tank

A technology of inclined bell jar and oil tank, applied in the direction of transformer/inductor cooling, etc., can solve the problems of high labor intensity, waste of man-hours, difficult operation, etc., and achieve the effect of reducing labor intensity, saving man-hours, and requiring less space for use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

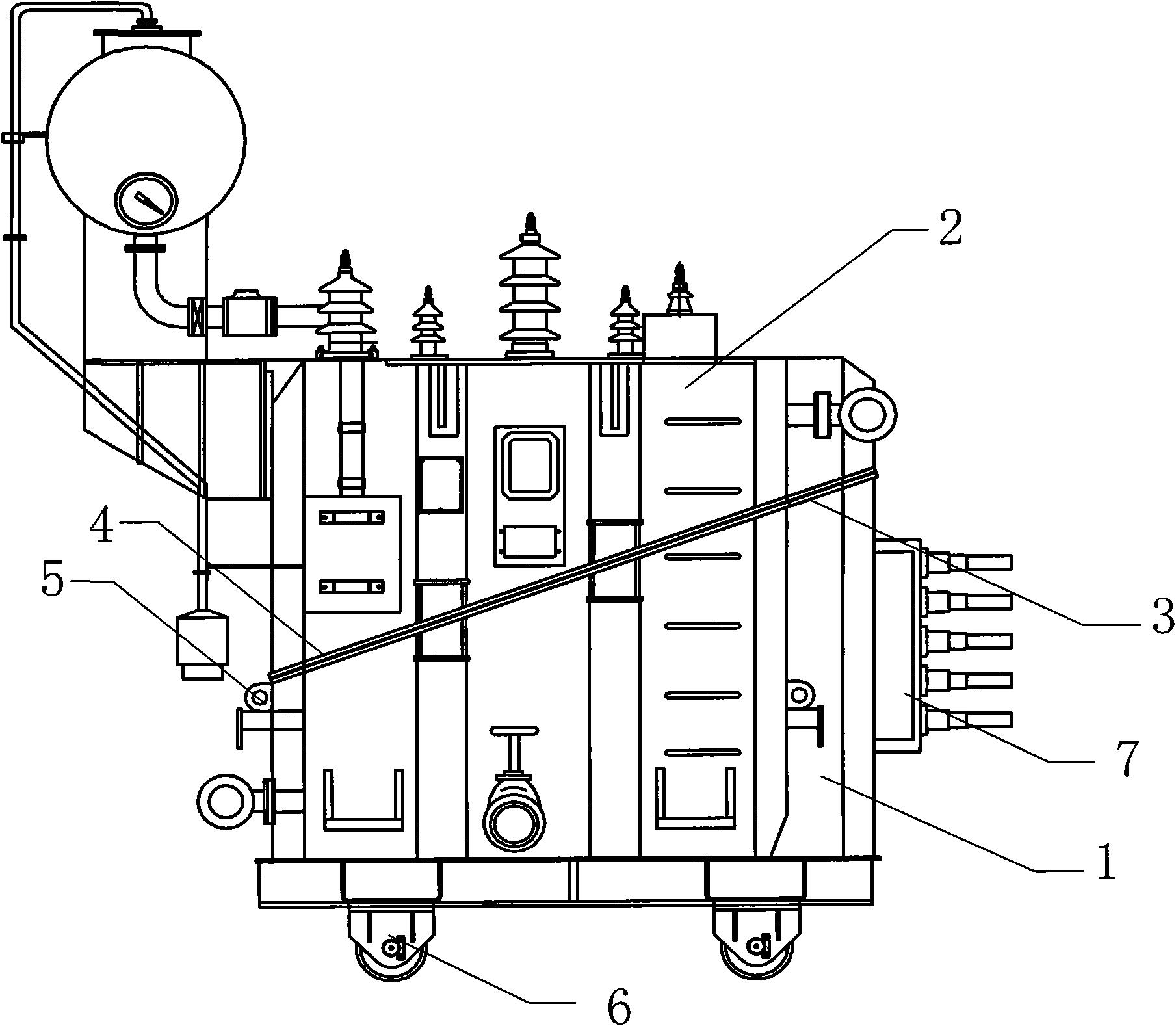

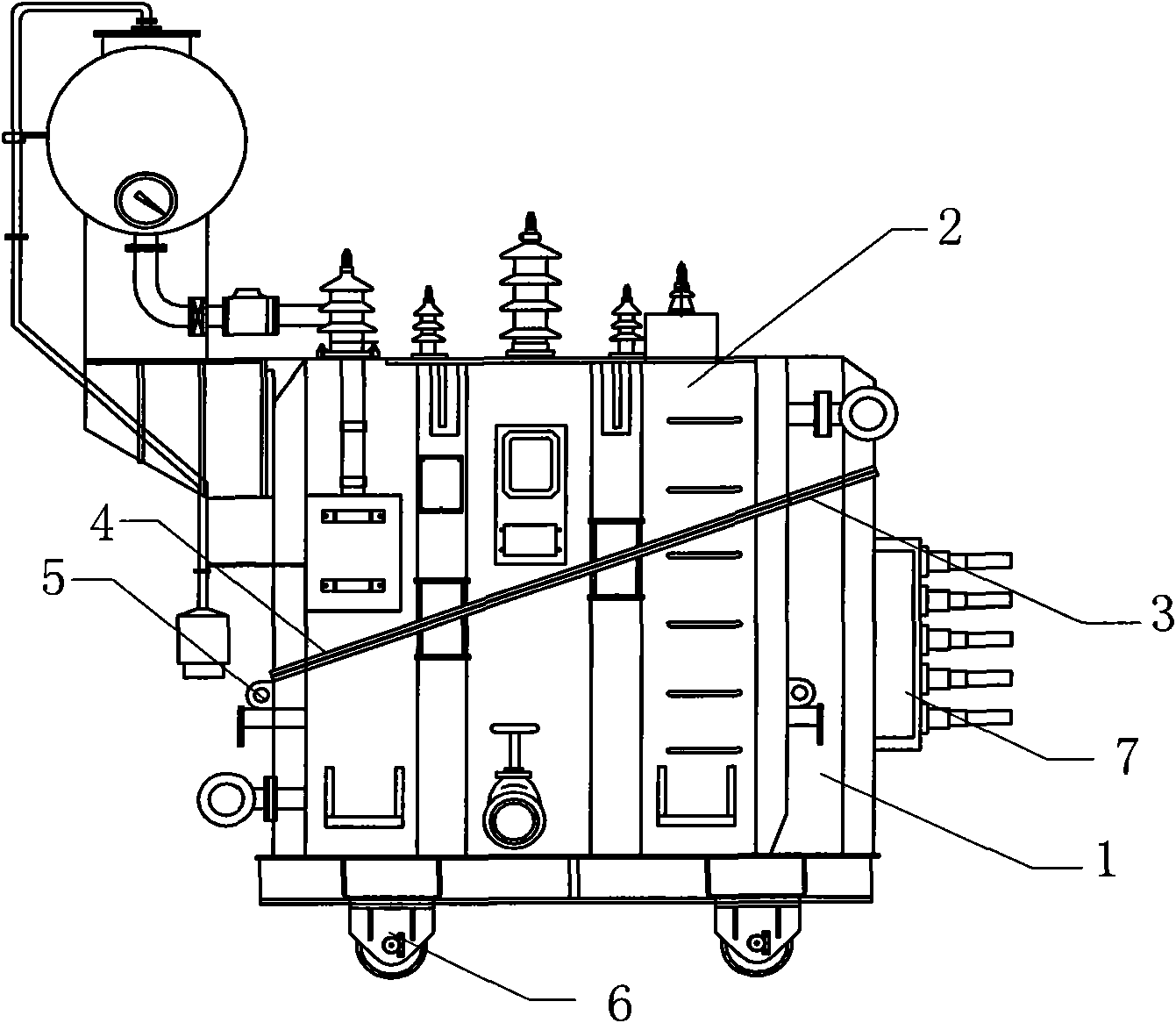

[0018] Such as figure 1 The shown bell type fuel tank includes a lower fuel tank 1, the lower fuel tank 1 is provided with a lower iron yoke, and its difference lies in that an upper joint is arranged on the top of the lower fuel tank 1. Fuel tank 2, and conversion control components are installed on the lower fuel tank 1. At the same time, the top of the lower fuel tank 1 is provided with an oblique main connecting edge 3 which is 15°-20° from the horizontal plane. Correspondingly, the bottom end of the upper fuel tank 2 is provided with a corresponding oblique secondary connecting edge 4, and the oblique primary connecting edge 3 and the oblique secondary connecting edge 4 form a connecting strip.

[0019] In view of a preferred embodiment of the present invention, in order to facilitate the stable integration of the inclined bell jar type fuel tank and facilitate the connection between the lower fuel tank 1 and the upper fuel tank 2, the oblique main connecting edge adopte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com