Vehicle loading method for large-scale tank body

A tank and large-scale technology, which is applied to the field of loading of super-large tanks, can solve the problems of difficult loading of large tanks, and achieve the effects of low loading cost, high safety factor, and simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

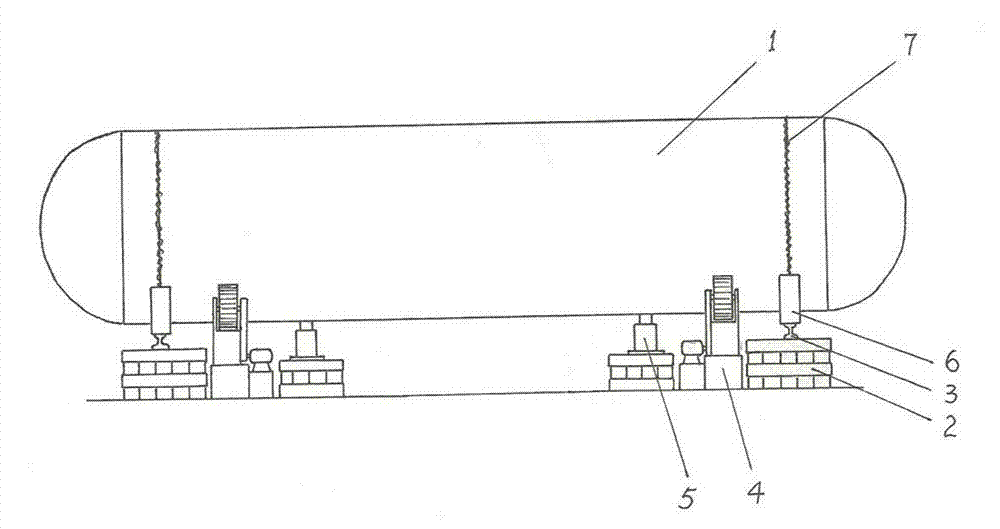

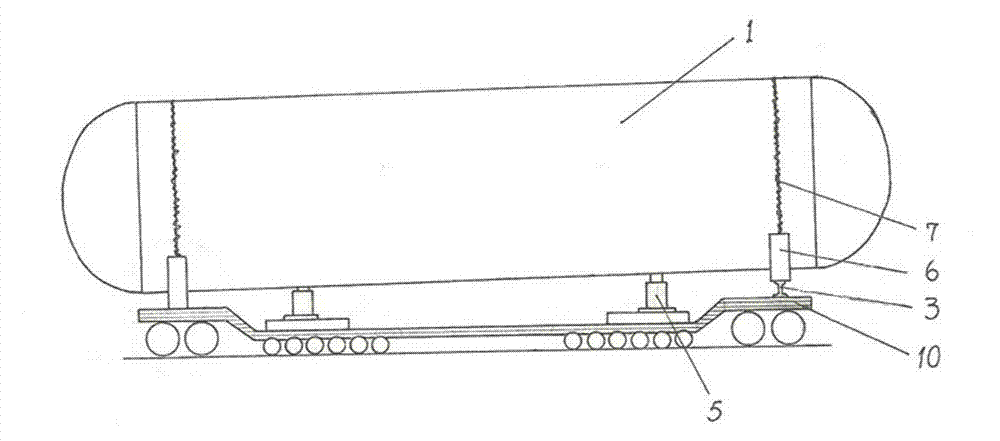

[0019] The loading method of the present invention is carried out according to the following steps.

[0020] 1. Tool preparation: several sleepers, two steel rails, two 200-ton hydraulic jacks, two hydraulic rail clamps, two hydraulic cylinders, and two sets of saddles.

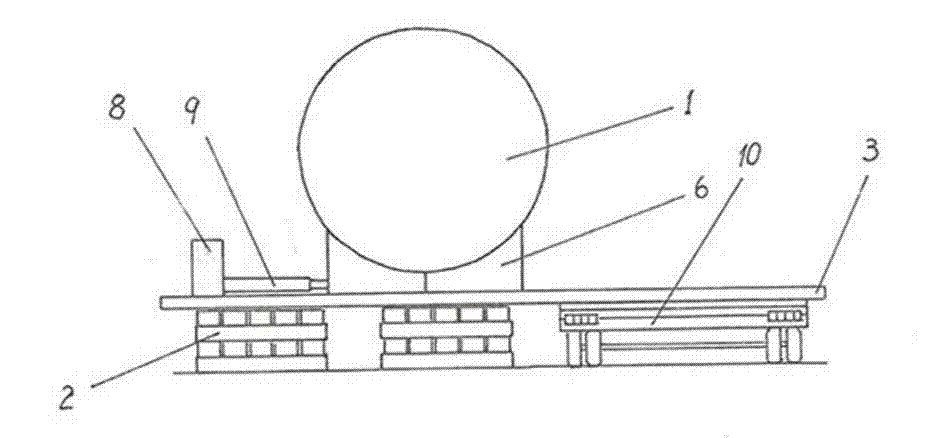

[0021] 2. Park the large-scale low-chassis transport vehicle 10 parallel to one side of the tank body 1 ( figure 2 ).

[0022] 3. If figure 1 As shown, a sleeper pile 2 with a height flush with the vehicle surface of the transport vehicle 10 is respectively erected with sleepers at the outer ends of the roller frame supports 4 (support mechanism used when making the tank body) at both ends of the tank body 1, and is ready A set of saddles 6; at the inboard end of the roller frame bearing 4 at the two ends of the tank body 1, a hydraulic jack 5 is supported with a sleeper, and the push rod of the jack is pushed against the bottom surface of the tank body 1.

[0023] 4. Manipulate the hydraulic jack 5 at on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com