A container bulk device

A technology for bulk device and container, applied in the field of container bulk device, can solve the problems of difficult loading, dust removal, low loading efficiency, data accuracy and accuracy cannot be guaranteed, etc., to improve the level of shipping intelligence, increase safety and Stability, the effect of improving the level of intelligent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

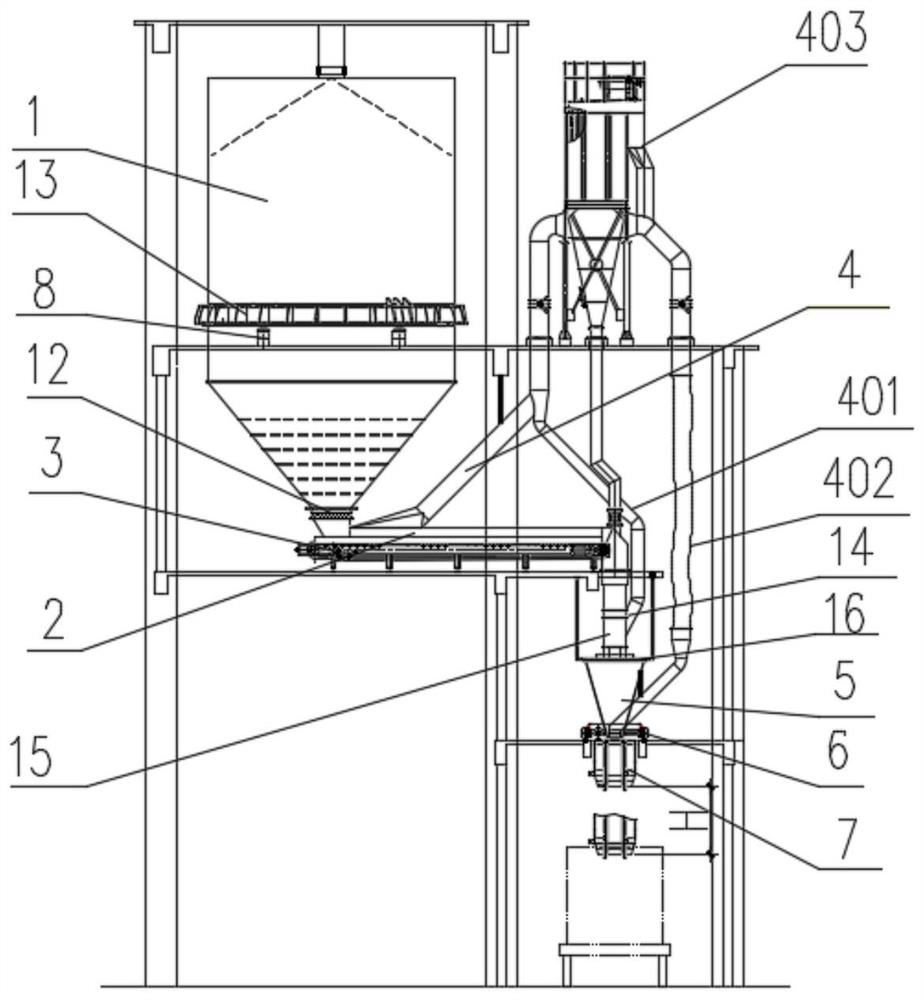

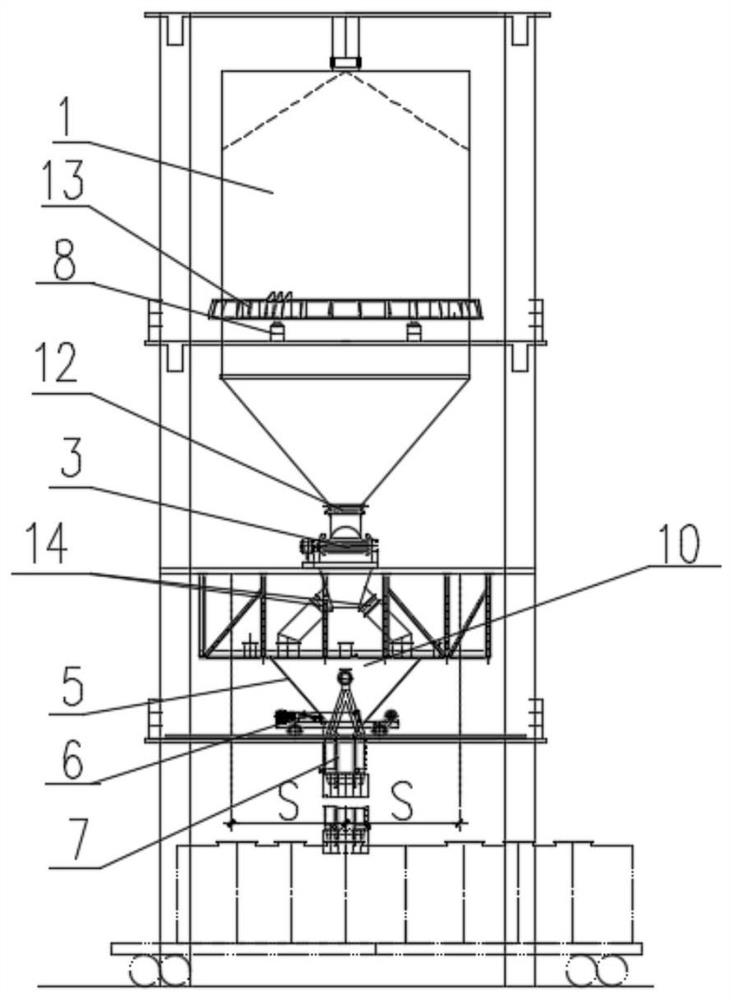

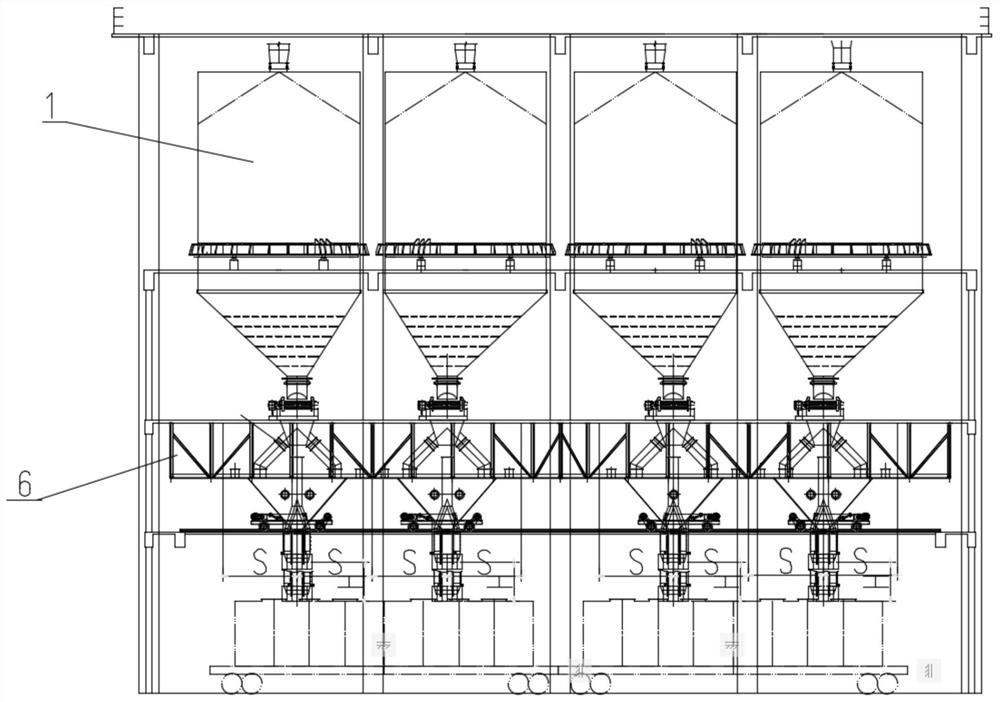

[0035] like Figures 1 to 2 , the silo 1 of the container bulk device is not rigidly connected to the structural frame, and there is a skirt 13 on the surface of the silo 1. The load sensor 8 that can measure the weight of the silo 1 in real time is installed under the skirt 13. The load sensor 8 can measure the weight of the silo 1 in real time and feed it back to the controller 9. The accuracy of the load sensor 8 is ±0.5%. There is a discharge valve 12 at the bottom of the silo 1 , and the discharge valve 12 is an electric valve or a pneumatic valve, which is connected with the controller 9 . The cone angle of silo 1 can be adjusted according to the fluidity of the material. In general, in order to ensure smooth material feeding, the cone angle of silo 1 should be greater than 38°; for limestone, cement clinker, etc., the cone angle of silo 1 is within Above 45°; for coal materials, the cone angle of silo 1 is above 60°; for cement with better fluidity, the cone angle can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com