An aerosol generator capable of simulating diesel engine exhaust particle flow

An aerosol generator and particle flow technology, which is applied in the direction of gas/steam and solid mixing, dissolution, colloid chemistry, etc., can solve the problem of single concentration adjustment means, achieve the effect of wide concentration range, expanded concentration range, and economical device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

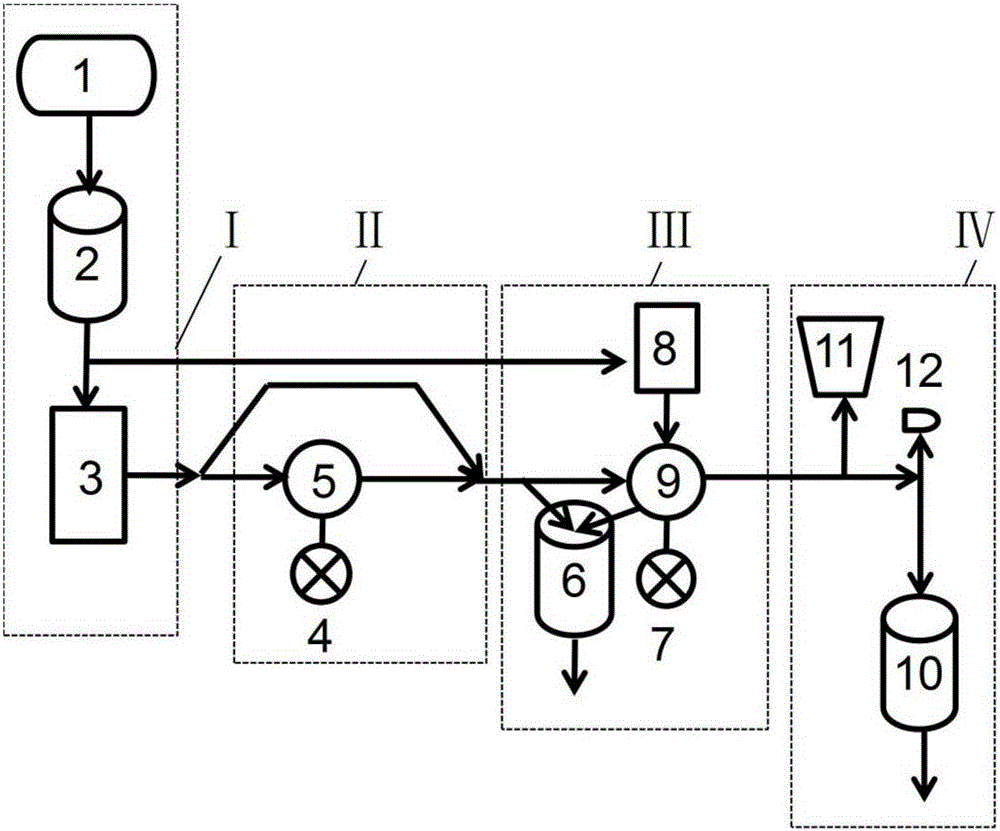

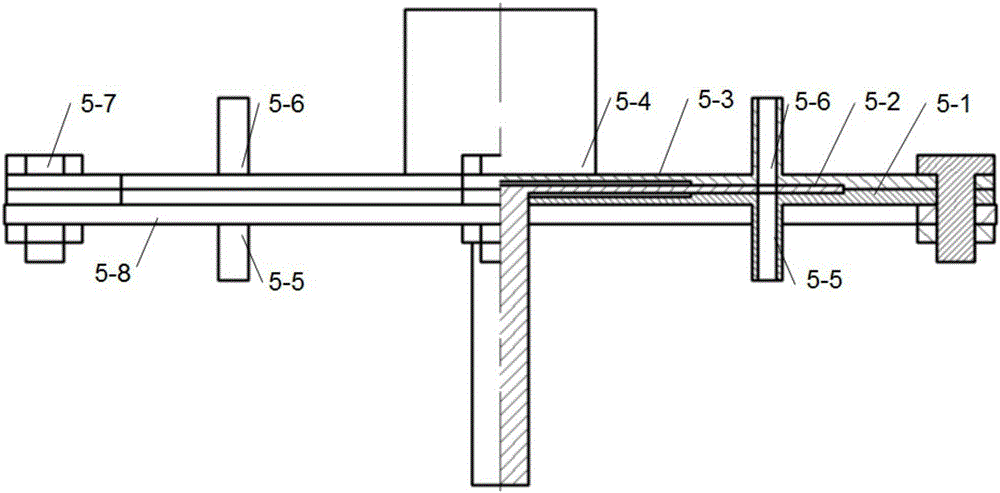

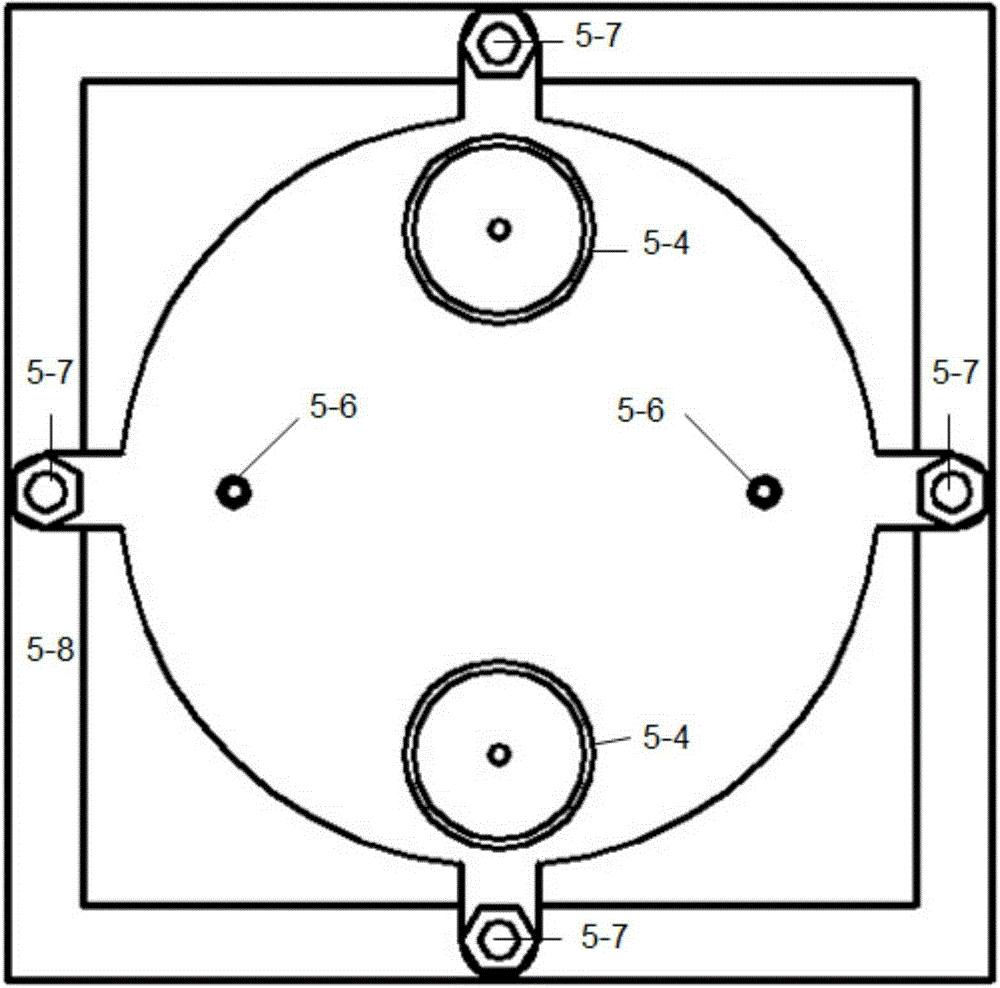

[0030] see figure 1 , the aerosol generator includes an air intake section, an aerosol generation section, an aerosol dilution section and a sampling section; the air intake section is used to provide stable and adjustable clean air, including an air compressor, an air filter, a quality Flow meter; the aerosol generation section is used to provide aerosol with stable concentration and quantitative quantity, including the base frame, rotating motor, and aerosol generation part, wherein the aerosol generation part includes a support plate, a turntable, a compression plate and a particle supply part The aerosol dilution section is used to dilute the aerosol to the required concentration in a certain proportion, including the base frame, rotating motor, mass flow meter, aerosol dilution part, DPF, wherein the aerosol dilution part includes a support plate, a turntable, a press Tight disk; the sampling section is used to provide collection, including DPF, concentration monitoring u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com