Quenching clamp of stationary integrated ring

A fixture and integrated technology, used in quenching devices, manufacturing tools, furnaces, etc., can solve problems such as workpiece deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

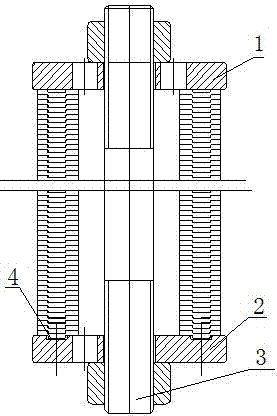

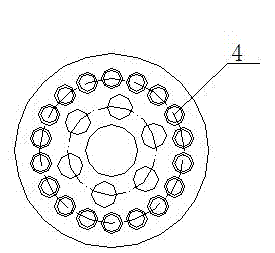

[0014] As shown in the figure: a fixed and fixed ring quenching fixture, including an upper splint 1, a lower splint 2, bolts 3, and a pit 4.

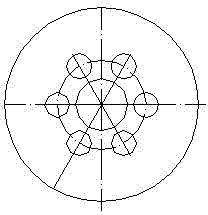

[0015] A through hole is arranged at the center of the upper splint 1 and the lower splint 2, and several through holes are distributed around the central through hole. Pit 4. The dimples 4 are evenly distributed on a central circumference of the lower splint 2 . When quenching and heating, the boss of the product is placed in the lower splint, so that the plane of the product is in contact with the plane of the lower splint, which can effectively reduce thermal deformation; several through holes distributed around the central through hole play the role of heat transfer; tempering The quenched parts are neatly superimposed on the lower splint, and the splint is added, fixed with bolts on the press, and then tempered, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com