Method and equipment for preparing semi-solid metal slurry/blank with current

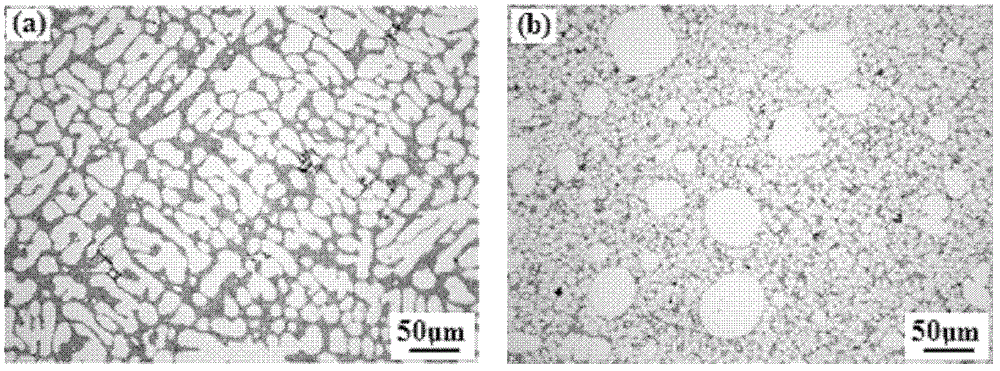

A semi-solid metal and billet technology, which is applied in the field of metal materials and metallurgy, can solve the problems that limit the progress of semi-solid forming technology, the life of the stirring rod is low, and it is easy to introduce inclusions, so as to achieve large market promotion value and reduce phase change activation. Can achieve uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

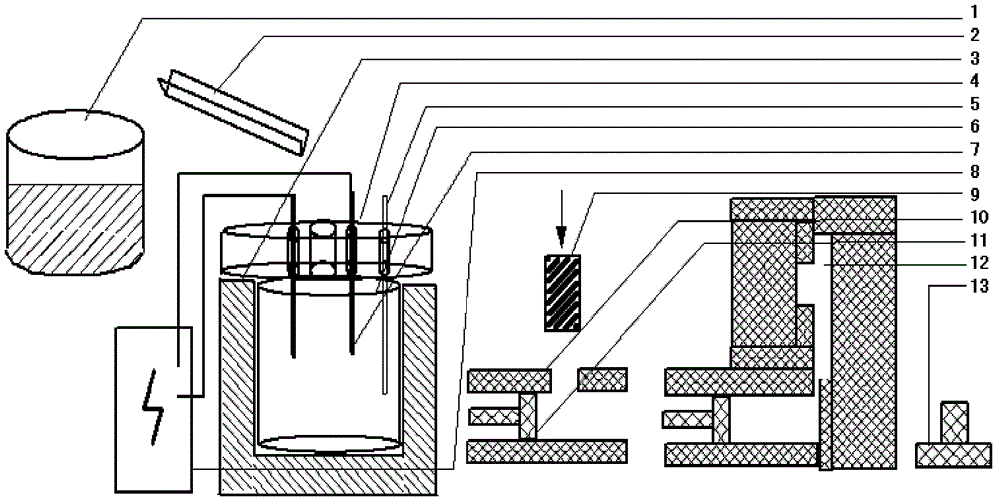

[0042] ZL101 aluminum alloy liquidus temperature T L =585.5℃, solidus temperature T S = 515.8°C. First, the alloy is melted in a resistance furnace, refined with hexafluoroethane at 650°C, left to stand for 15 to 30 minutes, then skimmed, refined into a semi-solid metal slurry / billet mother liquor 9, placed in the mother liquor crucible 1, and the temperature is controlled at In the range of 595°C to 615°C.

[0043] use figure 1 The process flow and equipment shown. Pour the semi-solid metal slurry / billet mother liquor 9 into the launder 2, and under the action of gravity, the semi-solid metal slurry / bill mother liquor 9 flows into the heat preservation crucible 6 by itself, and completes the cooling process in the launder 2, and the heat preservation crucible 6 is placed In the holding furnace 3, the temperature of the mother liquor is controlled within the range of 560°C to 580°C.

[0044] The current treatment device 7 adopts a direct current of 10A to conduct current ...

Embodiment 2

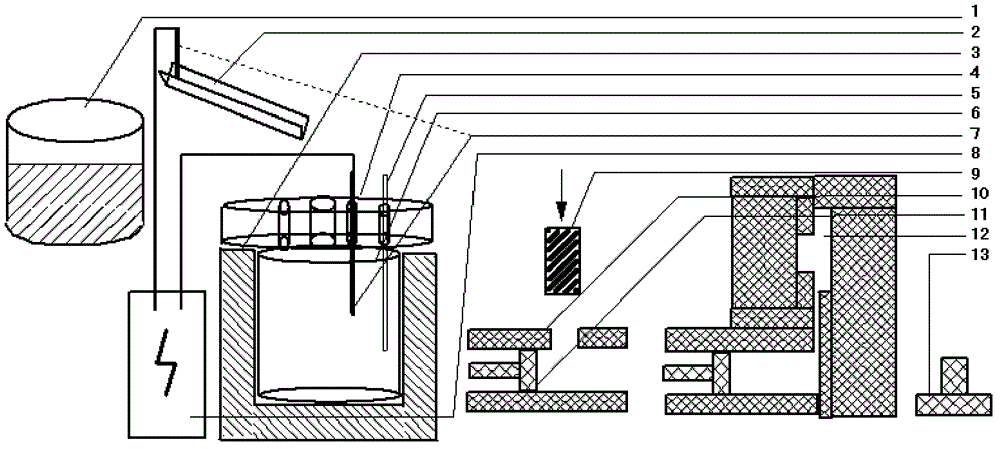

[0048] A390 aluminum alloy liquidus temperature T L =615.6℃, solidus temperature T S = 567.5°C. First, the alloy is melted in a resistance furnace, refined with hexafluoroethane at 720°C, left to stand for 15 to 30 minutes, then skimmed, refined into a semi-solid metal slurry / billet mother liquor 9, placed in the mother liquor crucible 1, and the temperature is controlled at In the range of 635°C to 655°C.

[0049] use figure 2 The process flow and equipment shown. Pour the semi-solid metal slurry / billet mother liquor 9 into the launder 2, and under the action of gravity, the semi-solid metal slurry / bill mother liquor 9 flows into the heat preservation crucible 6 by itself, and completes the cooling process in the launder 2, and the heat preservation crucible 6 is placed In the holding furnace 3, the temperature of the semi-solid metal slurry / billet mother liquor 9 is controlled within the range of 610°C to 630°C.

[0050] One electrode of the current processing device 7...

Embodiment 3

[0054] Liquidus T of AZ91D magnesium alloy L =595℃, solidus temperature T S = 470°C. First the alloy is melted in a resistance furnace, made of 2% SF 6 +CO 2 Protect, refine with JDMJ refining agent at 740°C, stand still for 10-30min, then carry out bottom removal and slag skimming, and refine into semi-solid metal slurry / billet mother liquor 9, place in mother liquor crucible 1, and semi-solid metal slurry / bill mother liquor The temperature of 9 is controlled within the range of 615°C to 635°C.

[0055] use figure 1 The process flow and equipment shown. The mother liquor is poured into the launder 2, under the action of gravity, the mother liquor flows into the heat preservation crucible 6 by itself, and the cooling process is completed in the launder 2. The holding crucible 6 is placed in the holding furnace 3, and the temperature of the mother liquor is controlled within the range of 590°C to 620°C.

[0056] The current treatment device 7 uses an alternating current ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| solidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com