Weft insertion apparatus in jet loom

A weft insertion device, jet loom technology, used in looms, textiles, textiles, and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

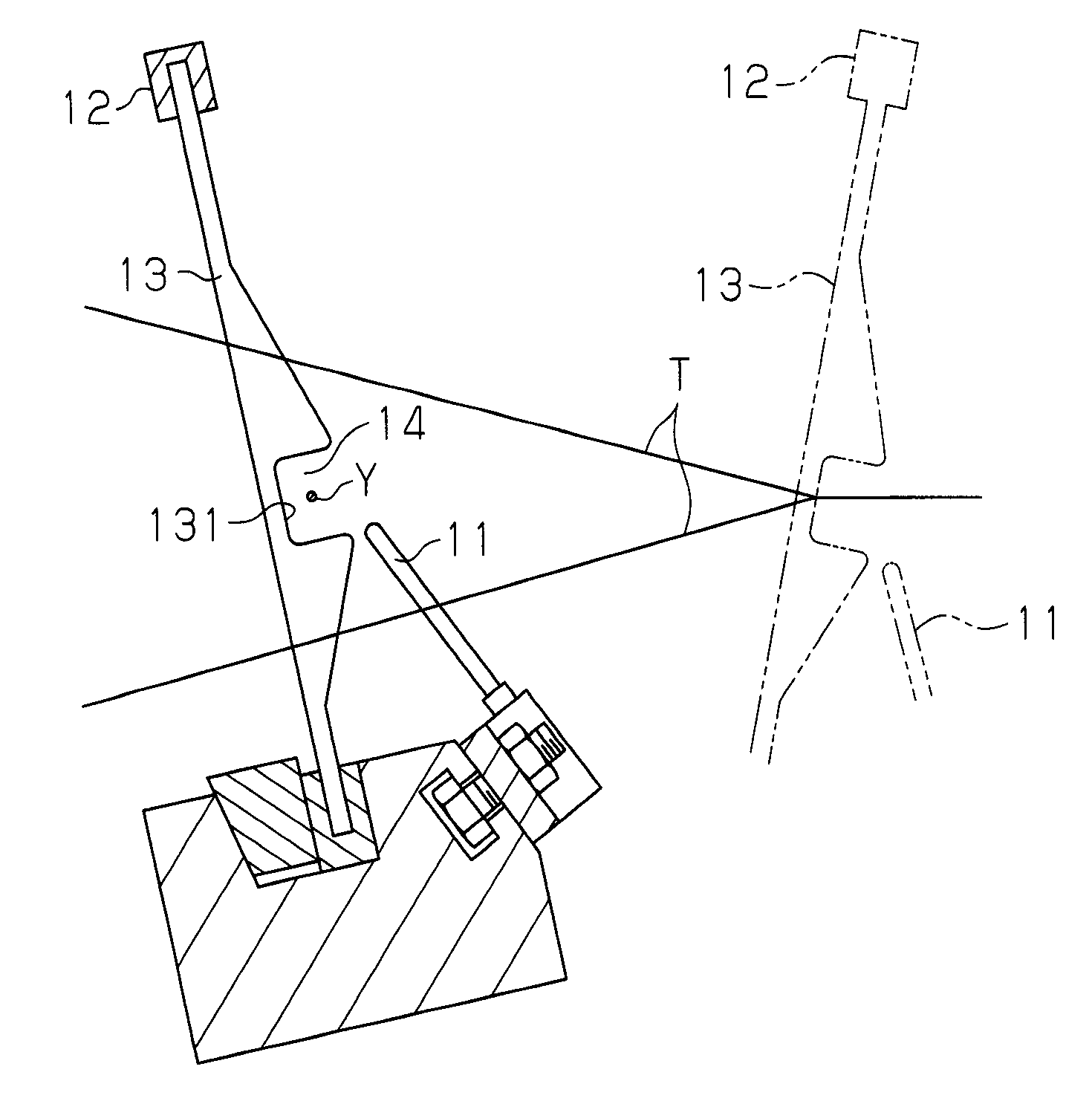

[0037] An embodiment of the present invention will be described with reference to FIGS. 1 to 8 . The overall structure of the weft insertion device including the auxiliary nozzle for weft insertion is the same as that in FIG. 9 .

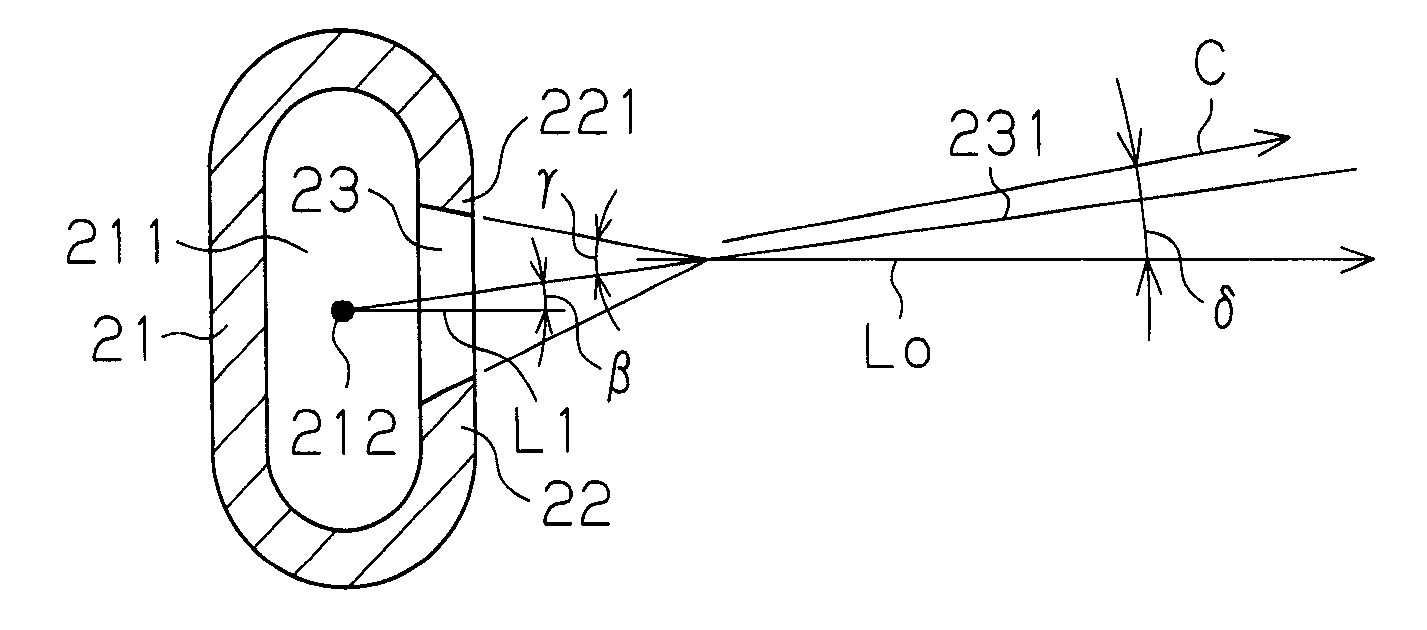

[0038] FIG. 1( a ) is a front view of a part of the auxiliary nozzle 21 for weft insertion and a part of the deformed reed 12 . Fig. 1(b) is a sectional view of Fig. 1(a) taken along line 1b-1b. FIG. 2( a ) is a side view of the tip of the auxiliary nozzle 21 . The tip of the auxiliary nozzle 21 is rounded or arcuate when viewed along the weft insertion direction Lo. Fig. 2(b) is a cross-sectional view of Fig. 2(a) taken along line 2b-2b. Figure 2(c) is a cross-sectional view of Figure 2(b) taken along line 2c-2c.

[0039] A single auxiliary nozzle 21 is provided in the figure. However, as the person skilled in the art realizes, each auxiliary nozzle 21 may be positioned for every certain number of reed teeth 13 in a weft thread arrangement.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com