Blade profile of sheet-shaped axial flow fan formed by adopting squeezing, pulling and cutting process

A technology of axial flow fan and thin plate type, which is applied in the fields of axial flow fan blade shape and thin plate axial flow fan blade shape, can solve the problems of low cost, many mold consumables, high manufacturing cost, etc. Can not be cut, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail as follows, present embodiment is based on the premise of the technical solution of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following implementation example.

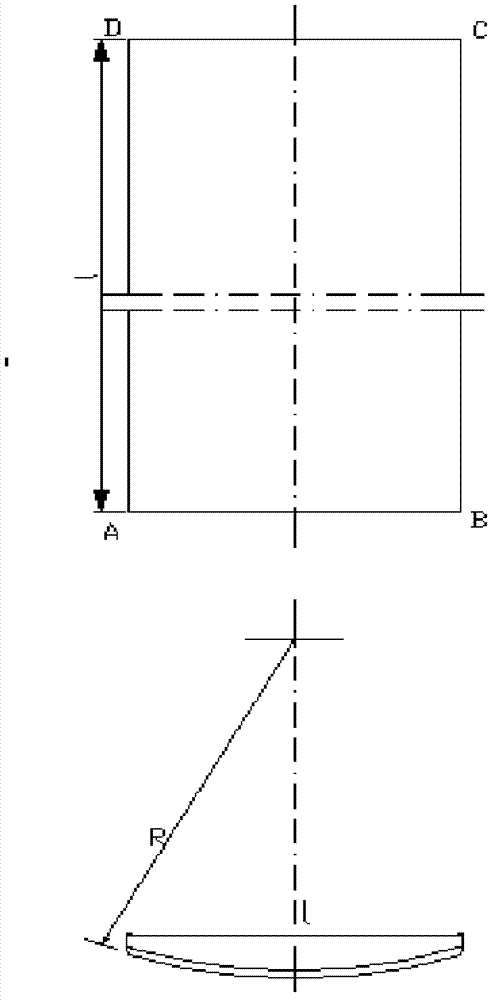

[0016] figure 1 It is the thin-plate axial flow fan blade blank material after extrusion molding.

[0017] The blank ABCD is composed of arc radius R, two parallel sides AD and BC on the left and right of the arc plate, the straight line distance between them is the chord length l, and AD is the length L of the arc plate in the blade length direction, which can be manufactured according to the plan The inner and outer diameters of the blade determine its length.

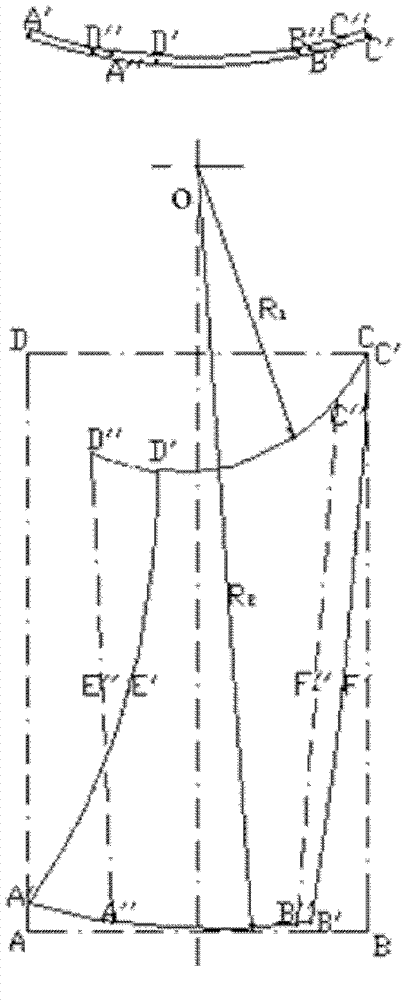

[0018] figure 2 It is the leaf diagram after cutting, and ABCD in the figure is the blank material before cutting.

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com