Centrifugal wind wheel, manufacturing method thereof and centrifugal fan with centrifugal wind wheel

A technology of centrifugal wind wheel and wheel cover, which is applied to components, mechanical equipment, machines/engines, etc. of elastic fluid pumping devices, which can solve the problems of complex design, reduced enterprise competitiveness, and high development costs, and achieve reduction The effects of processing manufacturing costs, improving air flow, and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

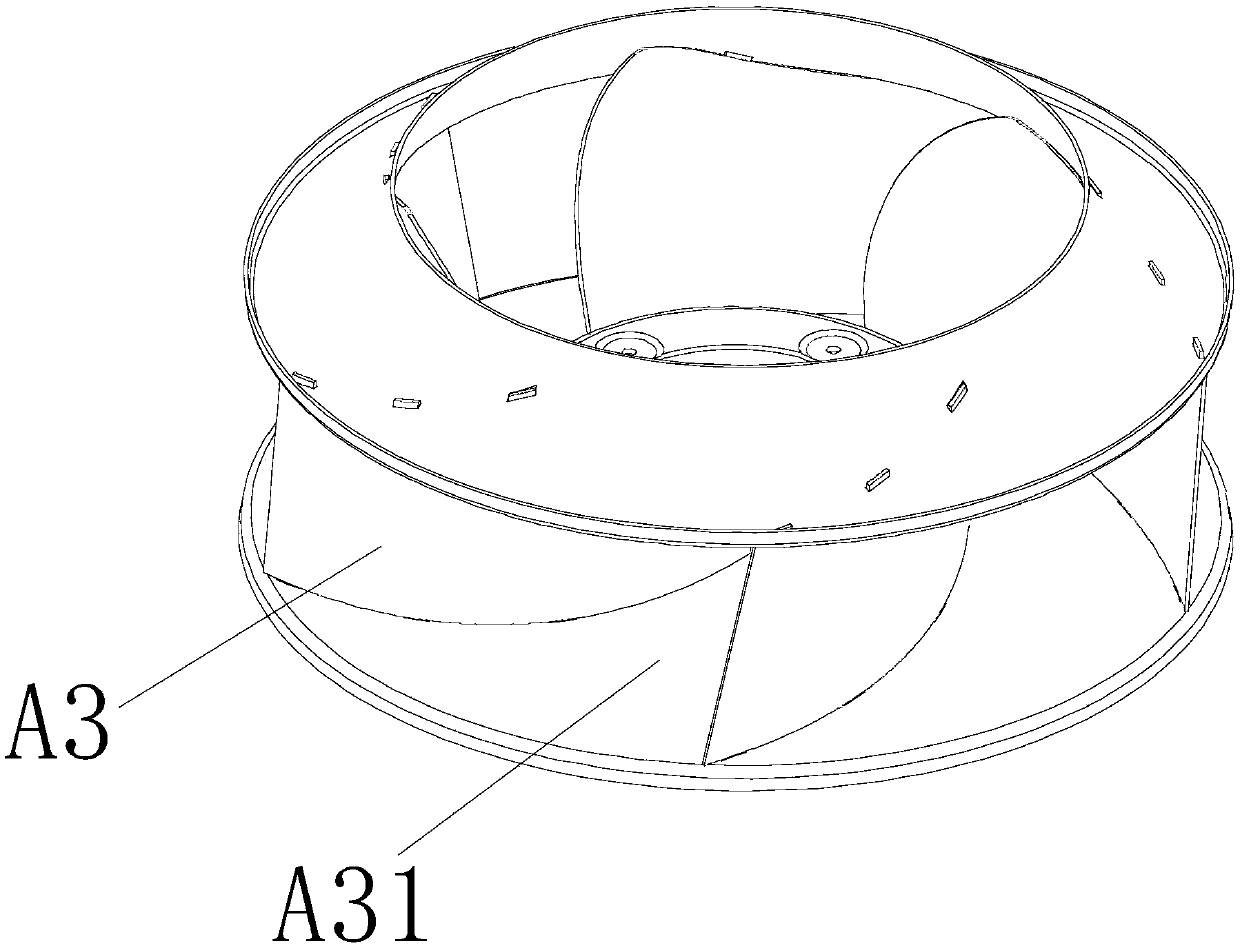

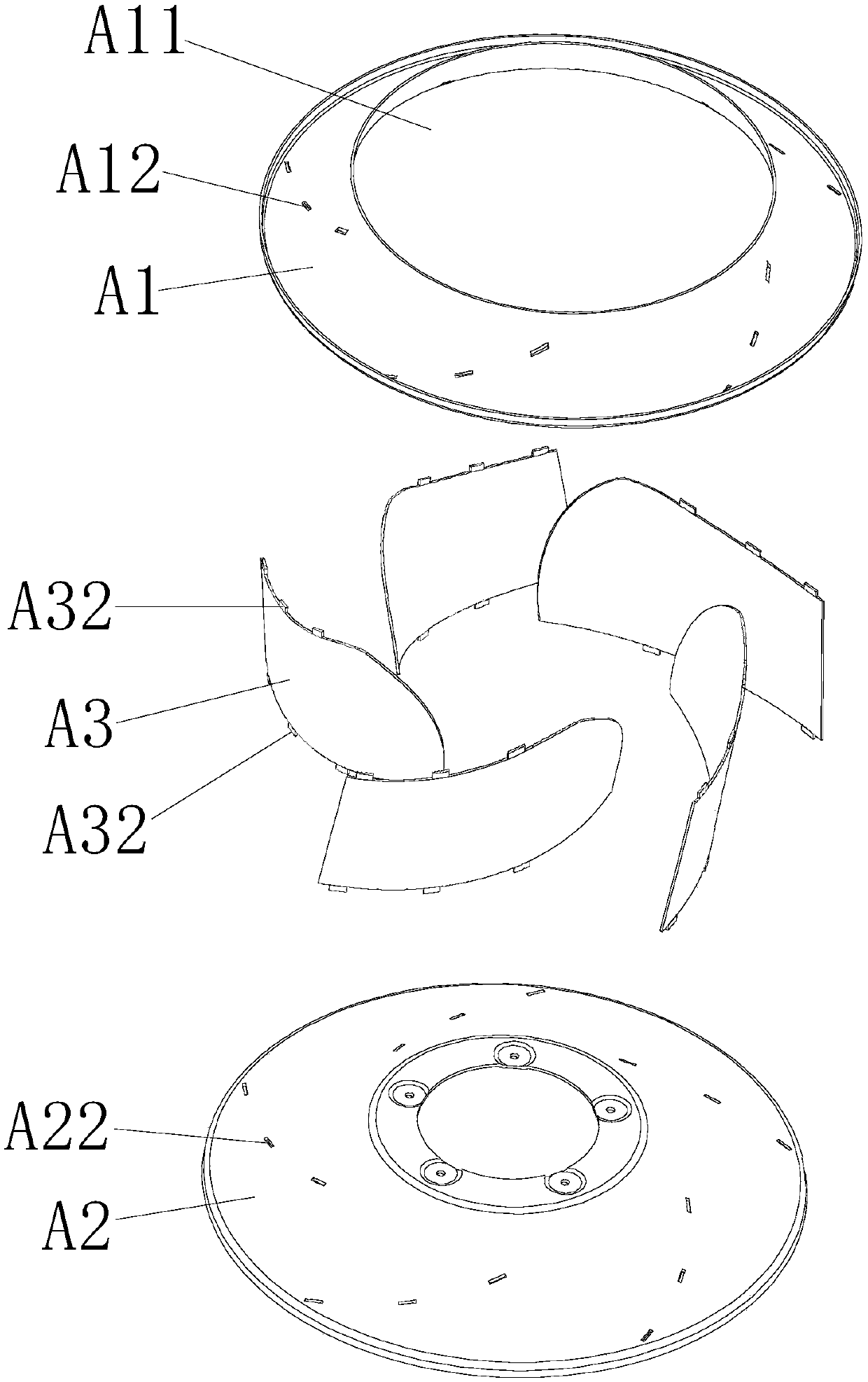

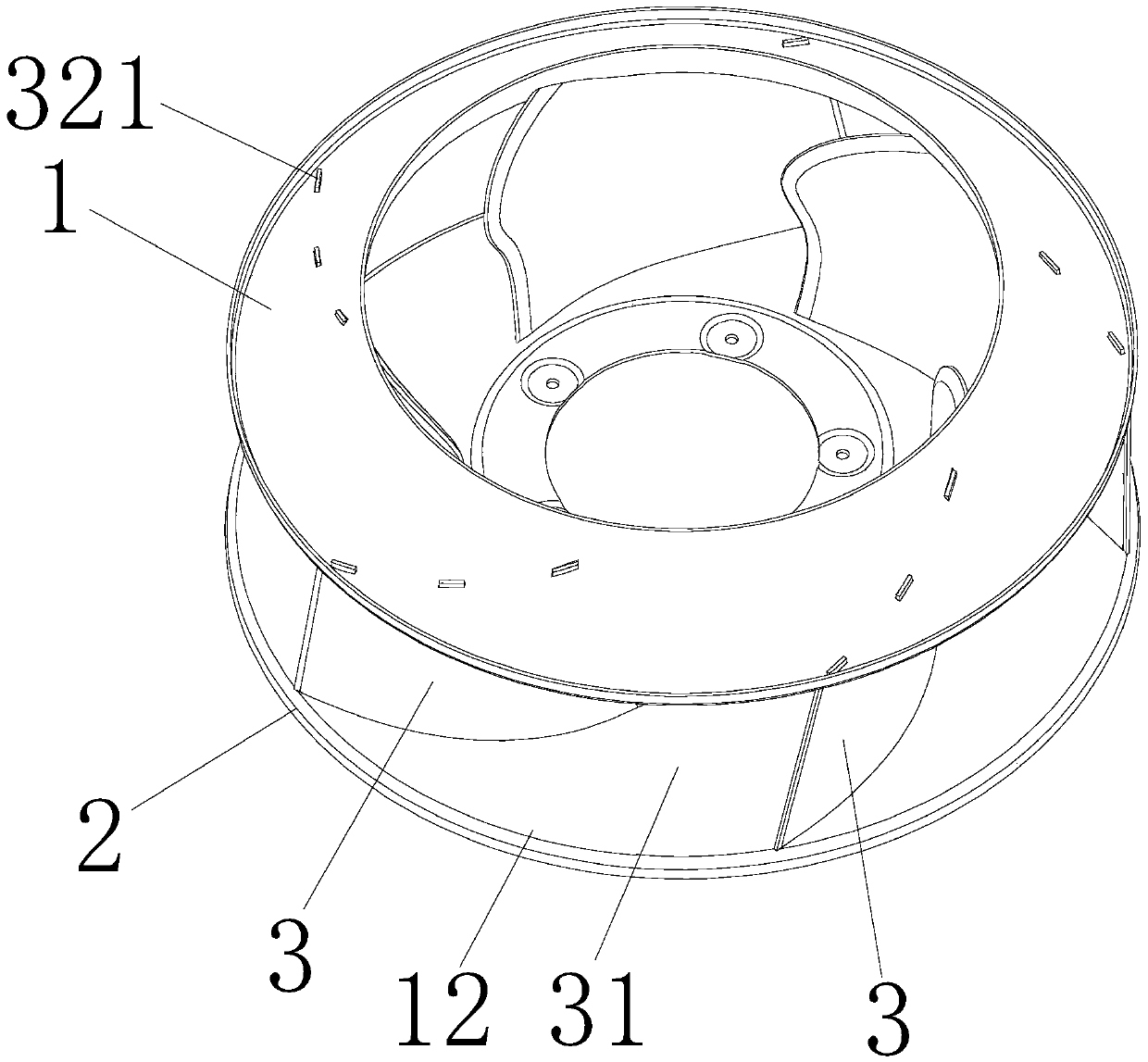

[0074] Such as Figure 3 to Figure 9 As shown, this embodiment is a centrifugal wind wheel, including a wheel cover 1 made of sheet metal, a wheel disc 2 made of sheet metal, and several wind blades 3 made of composite materials installed between the wheel cover 1 and the wheel disc 2 , the wheel cover 1 is provided with an air inlet 11, the center of the wheel disc 2 is provided with a motor installation position 21, an air duct 31 is formed between two adjacent wind blades 3, and an air duct 31 is formed at the end of the air duct 31. The tuyere 12 is characterized in that: the plurality of wind blades 3 made of composite materials include a metal frame 32 and a plastic shell 33 installed on the metal frame 32, and the upper and lower ends of the metal frame 32 are respectively connected to the wheel cover 1 and the wheel disc 2 Together, the thickness H of the plastic shell 33 is varied to improve air flow, the plastic shell 33 and the metal frame 32 are injection molded in...

Embodiment 2

[0105] Such as Figure 10 to Figure 15 As shown, this embodiment is a further improvement on the basis of Embodiment 1. The plastic shell 33 only wraps part of the skeleton main body 320 at the air inlet 11, and the rest of the skeleton main body 320 is exposed.

[0106] The thickness of the middle part 332 of the plastic shell 33 is the largest, the thickness from the air inlet end 331 to the middle part 332 gradually changes from small to large, and the thickness from the middle part 332 to the air outlet end 333 gradually changes from large to small. The outer thickness of the plastic shell can be changed in equal thickness or unequal thickness, and the maximum thickness can be realized at any radius on the blade in the gas flow channel.

Embodiment 3

[0108] A centrifugal fan, comprising a centrifugal wind wheel, a motor and a volute, the volute is provided with a second cavity capable of accommodating the centrifugal wind wheel, the volute includes an air inlet and an air outlet, and the air inlet and the air outlet The tuyeres are respectively communicated with the second cavity, and the centrifugal wind wheel is installed on and driven by the motor, and the centrifugal wind wheel is the centrifugal wind wheel described in any one of the first embodiment or the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com