Absorption-compression-type dual-purpose second species heat pump system

A heat pump system, compression technology, applied in lighting and heating equipment, fluid circulation arrangements, refrigeration components, etc., can solve the problems of reduced heating temperature rise, affecting the scope of application, and poor technical and economic performance, etc., to achieve flexibility The effect of adjustment, good adjustment, and large application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

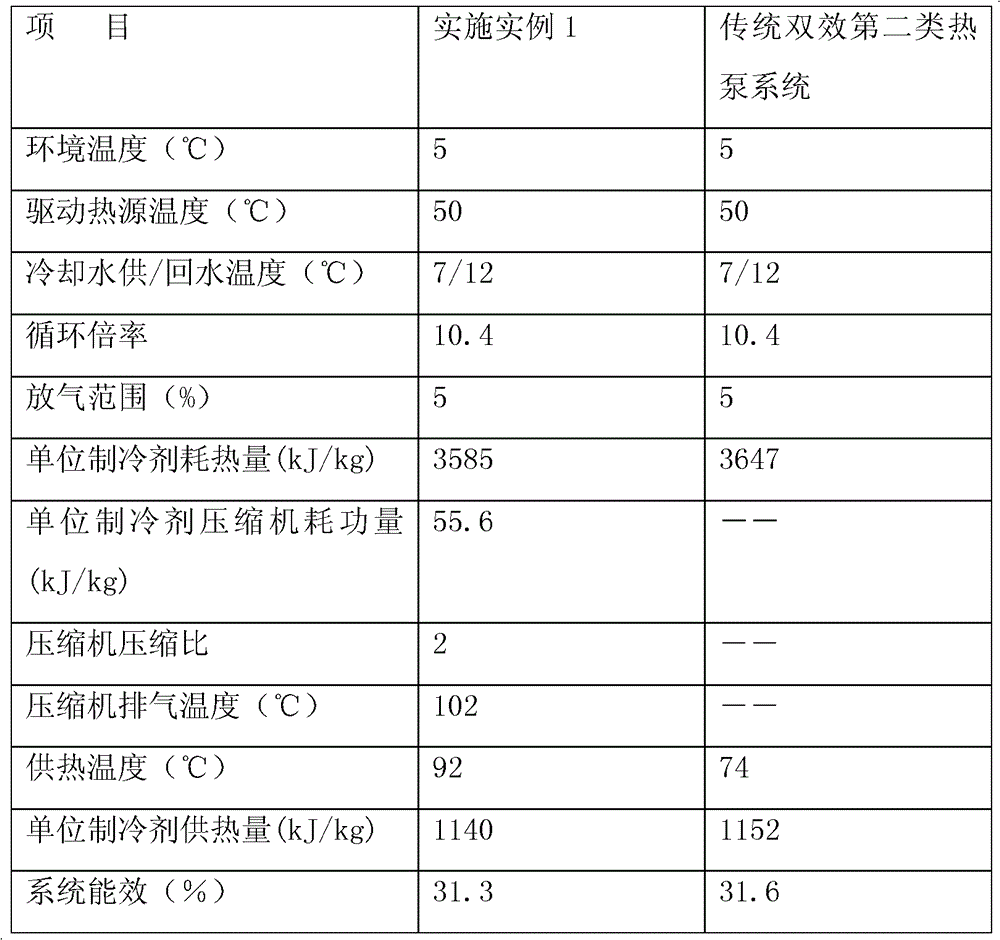

Embodiment 1

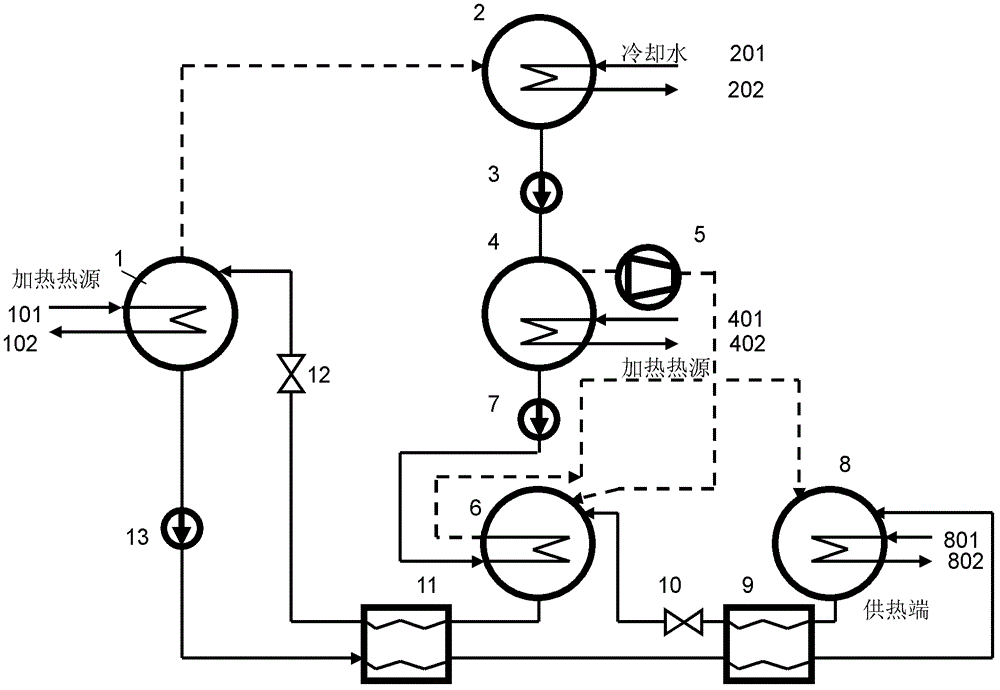

[0035] Embodiment 1, figure 1 An absorption-compression double-effect second-type heat pump system is given, which is composed of a refrigerant pipeline system and a solution pipeline system; the refrigerant pipeline system includes a condenser 2, a first refrigerant pump 3, and an evaporator 4 , compressor 5, second refrigerant pump 7; solution pipeline system includes generator 1, second absorber 6, first absorber 8, first solution heat exchanger 9, first throttling element 10, second The solution heat exchanger 11, the second throttling element 12 and the solution pump 13; the compressor 5 is an inverter compressor.

[0036] The gaseous refrigerant outlet of the generator 1 is connected to the gaseous refrigerant inlet 2 of the condenser, the liquid refrigerant outlet of the condenser 2 is connected to the first refrigerant pump 3, and the first refrigerant pump 3 is connected to the liquid refrigerant inlet of the evaporator 4, The gaseous refrigerant outlet of the evapor...

Embodiment 2

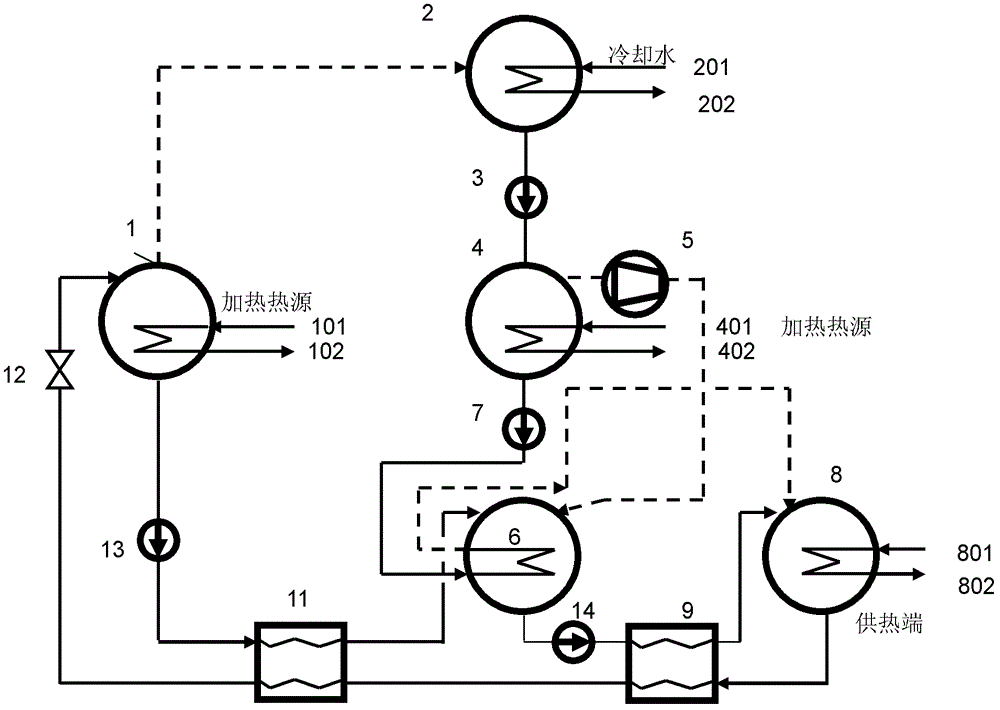

[0051] Embodiment 2, figure 2 Another absorption-compression double-effect heat pump system of the second type is given, which is composed of a refrigerant pipeline system and a solution pipeline system;

[0052] The refrigerant pipeline system includes a condenser 2, a first refrigerant pump 3, an evaporator 4, a compressor 5 and a second refrigerant pump 7; the solution pipeline system includes a generator 1, a second absorber 6, a first absorber 8, the first solution heat exchanger 9, the second solution heat exchanger 11, the second throttling element 12, the solution pump 13 and the additional solution pump 14; the compressor 5 is an inverter compressor.

[0053] The gaseous refrigerant outlet of the generator 1 is connected to the gaseous refrigerant inlet of the condenser 2, the liquid refrigerant outlet of the condenser 2 is connected to the first refrigerant pump 3, and the first refrigerant pump 3 is connected to the liquid refrigerant inlet of the evaporator 4, Th...

Embodiment 2

[0060] Implementation Example 2 The circulation process of the refrigerant piping system under the winter working conditions is the same as that of the implementation example 1, except that the circulation of the solution piping circulation system is the lithium bromide concentrated solution flowing out from the solution outlet of generator 1 (t=40°C, ζ =51.8%) is pressurized by the first solution pump 13 to become the re-cooled liquid under the working pressure of the second absorber 6, and the re-cooled liquid flows into the second solution heat exchanger 11, and is carried out with the lithium bromide solution from the first absorber 8 After heat exchange, after being heated (81.8°C), it flows into the second absorber 6. After absorbing the refrigerant vapor, the concentration of lithium bromide solution decreases (t=79.4°C, ζ=49.3%), and then the solution exits from the second absorber 6 It flows out and is pressurized to the working pressure of the first absorber 8 by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com