Device and method for positioning sensing element of displacement sensor

A displacement sensor and sensing element technology, applied in measuring devices, instruments, etc., can solve the problems of reducing industrial production efficiency, reducing the one-time pass rate of sensing element installation and positioning process, and increasing measurement error, so as to improve the process level and production efficiency , Improve the first pass rate and reliability, and improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

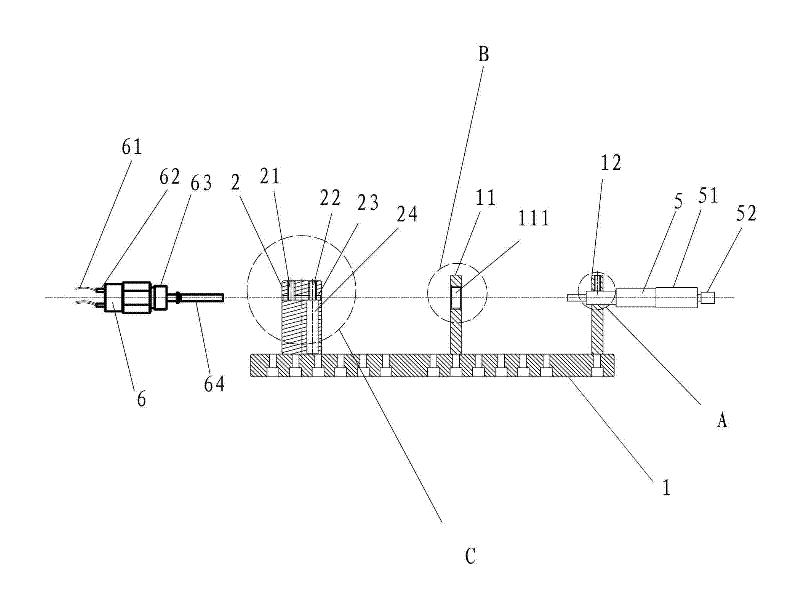

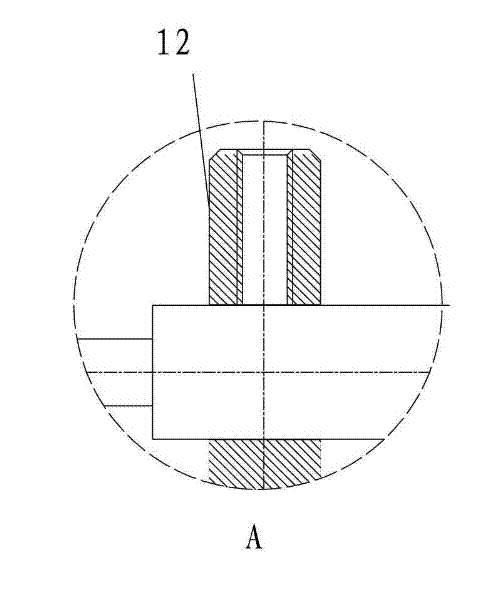

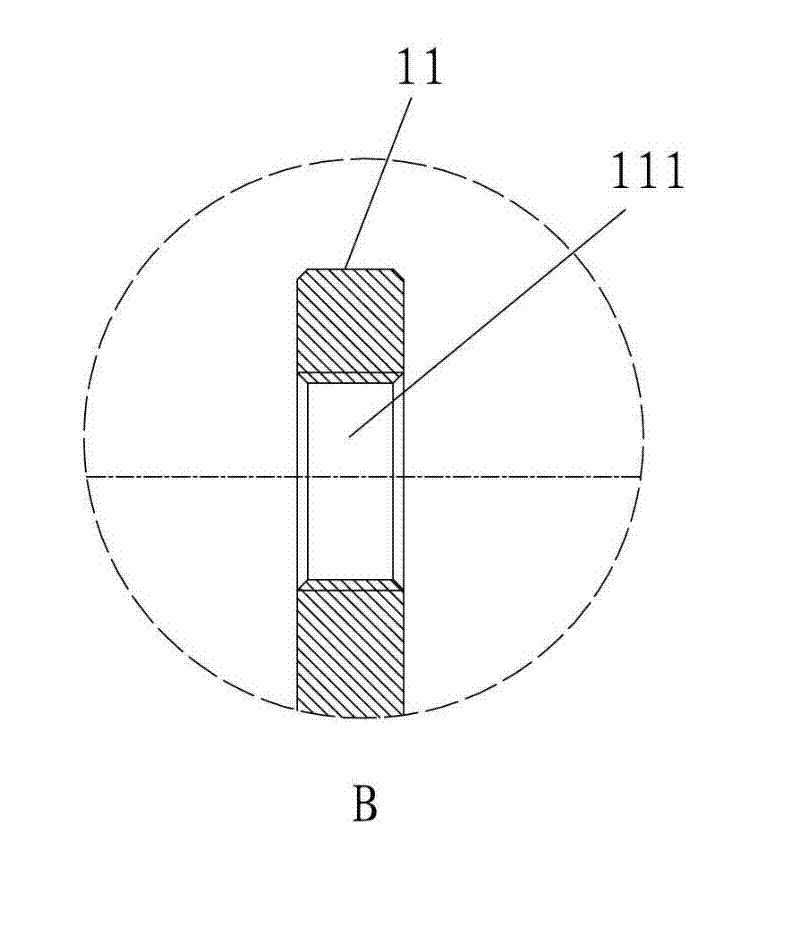

[0018] refer to Figure 1 to Figure 4 , a positioning device for a displacement sensor inductive element of the present invention, which includes a base 1, on which a lead fixing frame 2, a sensor fixing plate 11 and a measuring instrument fixing plate 12 are vertically arranged from left to right, The base 1 is integrally cast with the sensor fixing plate 11 and the measuring instrument fixing plate 12, and the base 1 is molded by one-time casting, the process is simple, and the operation is convenient. A displacement measuring instrument is welded in the through hole of the measuring instrument fixing plate 12 for accurately setting the installation position of the sensing element 62 . The sensor fixing plate 11 is drilled with a screw hole 111 for installing the sensor (inductive element to be installed), so that the sensor 6 to be installed with the inductive element can be installed on the base 1 conveniently, quickly and simply; The lead wire fixing frame 2 is fixedly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com