Vertical Zener diode structure and preparation method thereof

A technology of Zener diodes and injection regions, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of clamping circuit reliability, Zener breakdown value drift, product failure, etc., and improve product quality. Reliability, the effect of improving the drift of Zener breakdown value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

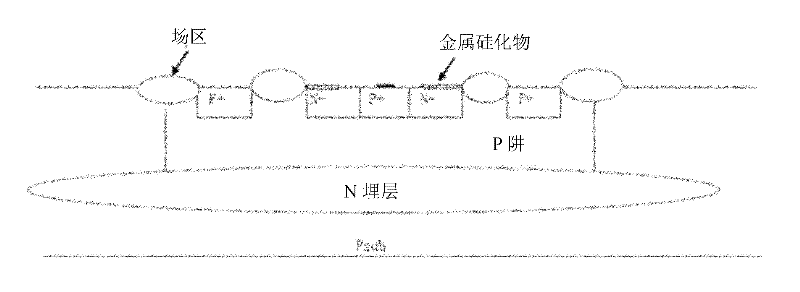

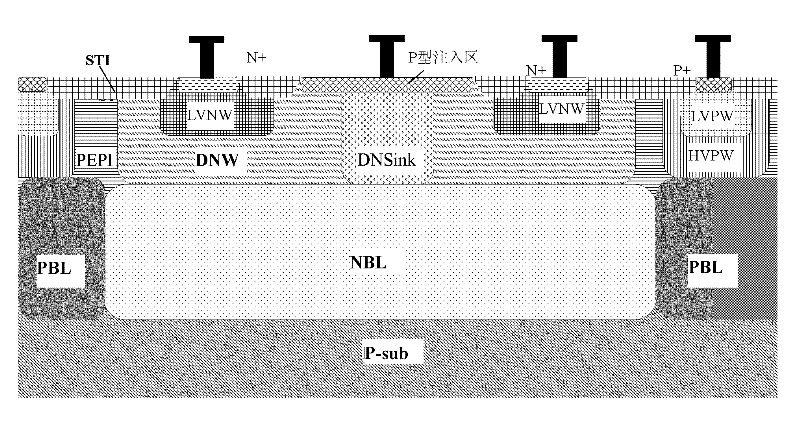

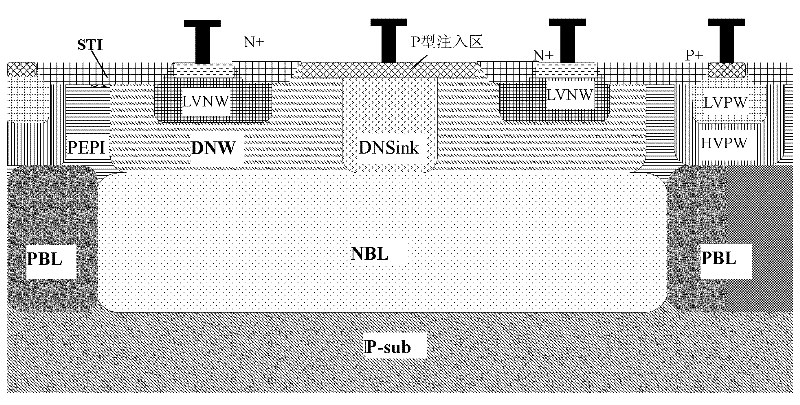

[0016] In the present invention, a vertical zener diode structure is adopted, with a built-in buried PN junction, which can improve the breakdown voltage. The vertical structure from the silicon surface to the bottom is a P-type implantation region (for shallow implantation), and the surface density is 1015 atoms. The order of magnitude per square centimeter; the N-type implantation region (for deep layer implantation), located below the P-type implantation region, has a surface density of 1014 atoms / square centimeter to 1015 atoms / square centimeter; the entire P-type implantation region and N-type implantation region are made in In an epitaxial layer with a deep N well, a dense N-type buried layer can be connected below, and the surface density is on the order of 1015 atoms / cm2. In a preferred embodiment, the vertical depth of the P-type implantation region is greater than or equal to 0.2 microns. In the vertical diode structure of the present invention, the zener breakdown p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com