On-pile travelling device

A technology of walking device and supporting legs, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc. It can solve the problems of difficulty in adapting to piling requirements, low piling efficiency, and heavy piling equipment, etc., and achieves reduced processing workload and simple structure Reliable, motion-controlled results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

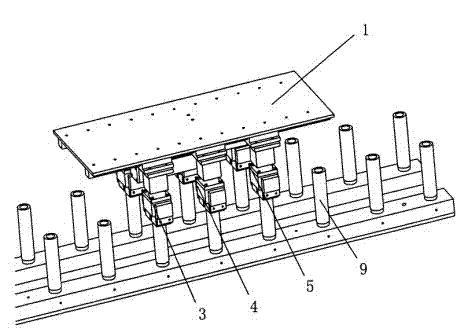

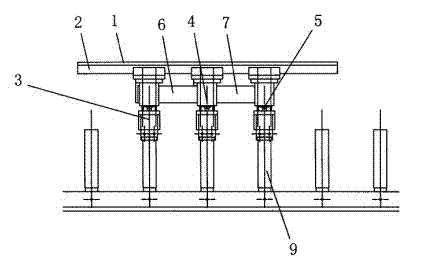

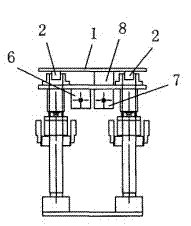

[0024] like Figure 1~5 As shown, a walking device on a pile includes a frame 1, a guide rail 2, a front group of support legs 3, a middle group of support legs 4, a rear group of support legs 5, a front horizontal cylinder 6, a rear horizontal cylinder 7, and a frame connecting plate 8. The support leg 4 of the middle group is fixedly connected with the frame 1 through the frame connecting plate 8, the support leg 3 of the front group is connected with the support leg 4 of the middle group through the front horizontal cylinder 6, and the support leg 4 of the middle group is connected with the rear horizontal cylinder 7 through the rear horizontal cylinder 7. The group of support legs 5 is connected, and the guide rail 2 has two left and right, and is fixed on the frame 1 respectively.

[0025] like image 3 , 4 As shown, the front group of support legs 3, the middle group of support legs 4 and the rear group of support legs 5 are all made up of a left leg 18, a right leg 19...

Embodiment 2

[0028] like Image 6 Shown, front additional group support leg 14 is also provided with in the front of front group support leg 3, front additional group support leg 14 links to each other with front group support leg 3 by front additional cylinder 15; 18. The right leg 19, the leg connecting plate 20, the left slider 21 and the right slider 22 are composed, wherein the left leg 18 and the right leg 19 are respectively fixed at the two ends of the lower side of the leg connecting plate 20, and the left The slide block 21 and the right slide block 22 are respectively fixed on the two ends of the upper side of the leg connecting plate 20 , and are slidably fitted with the guide rail 2 fixed on the frame 1 .

[0029] like Image 6 Shown, also be provided with rear additional group support leg 16 in the back of rear group support leg 5, rear additional group support leg 16 links to each other with rear group support leg 5 by rear additional cylinder 17, rear additional group supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com