Efficient gas extraction method for up-and-down combined fracturing area of broken soft low-permeability coal seam well

A technology for coal seam and extraction, which is applied to the field of gas efficient extraction in the upper and lower combined fracturing area of crushed soft and low permeability coal seams, and can solve the problems of small injection and displacement of fracturing pump, difficult equipment handling, and poor coal seam gas extraction effect. , to achieve the effect of reducing gas content and gas pressure, shortening fracturing construction time and cost, and reducing gas drainage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

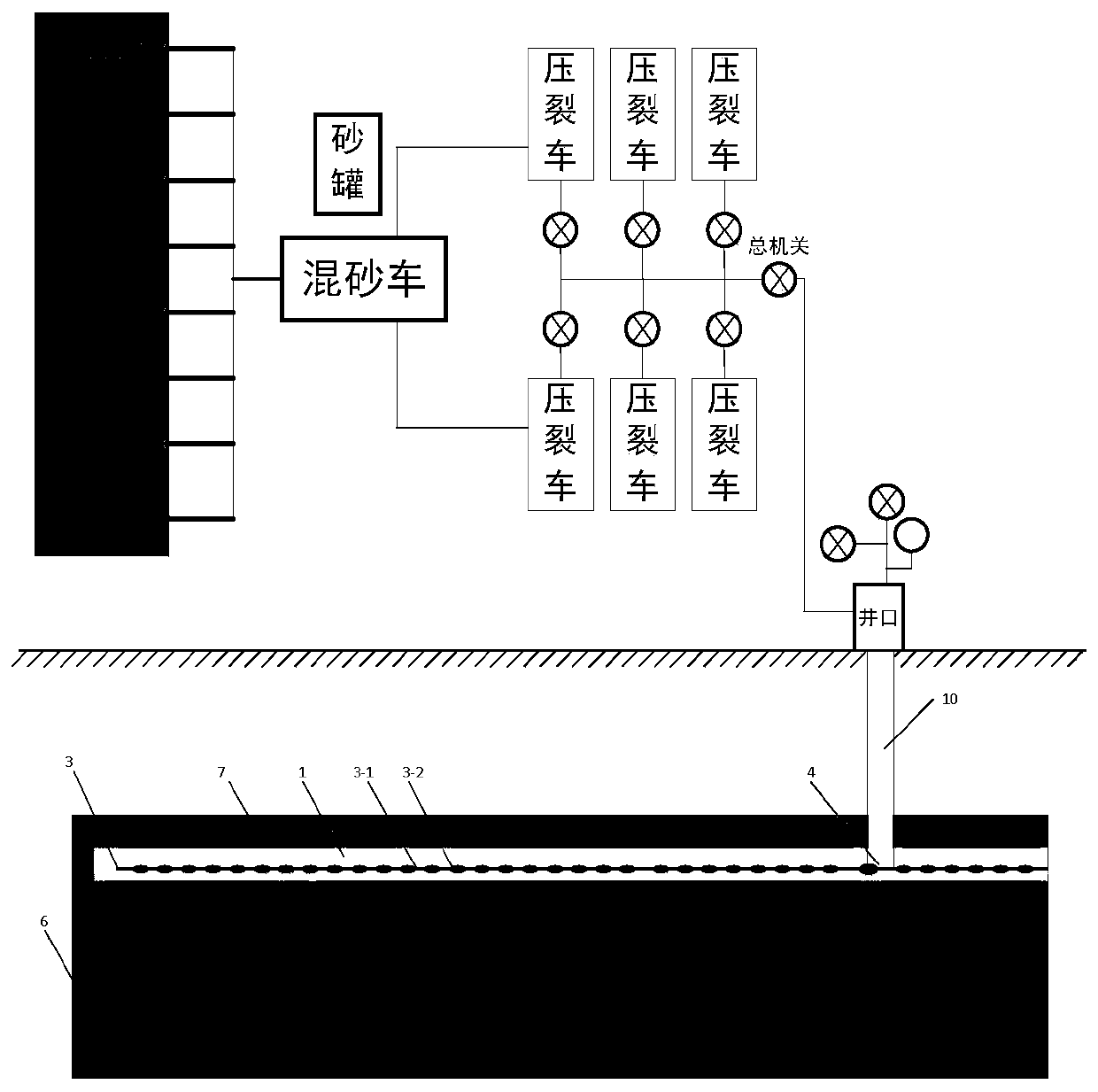

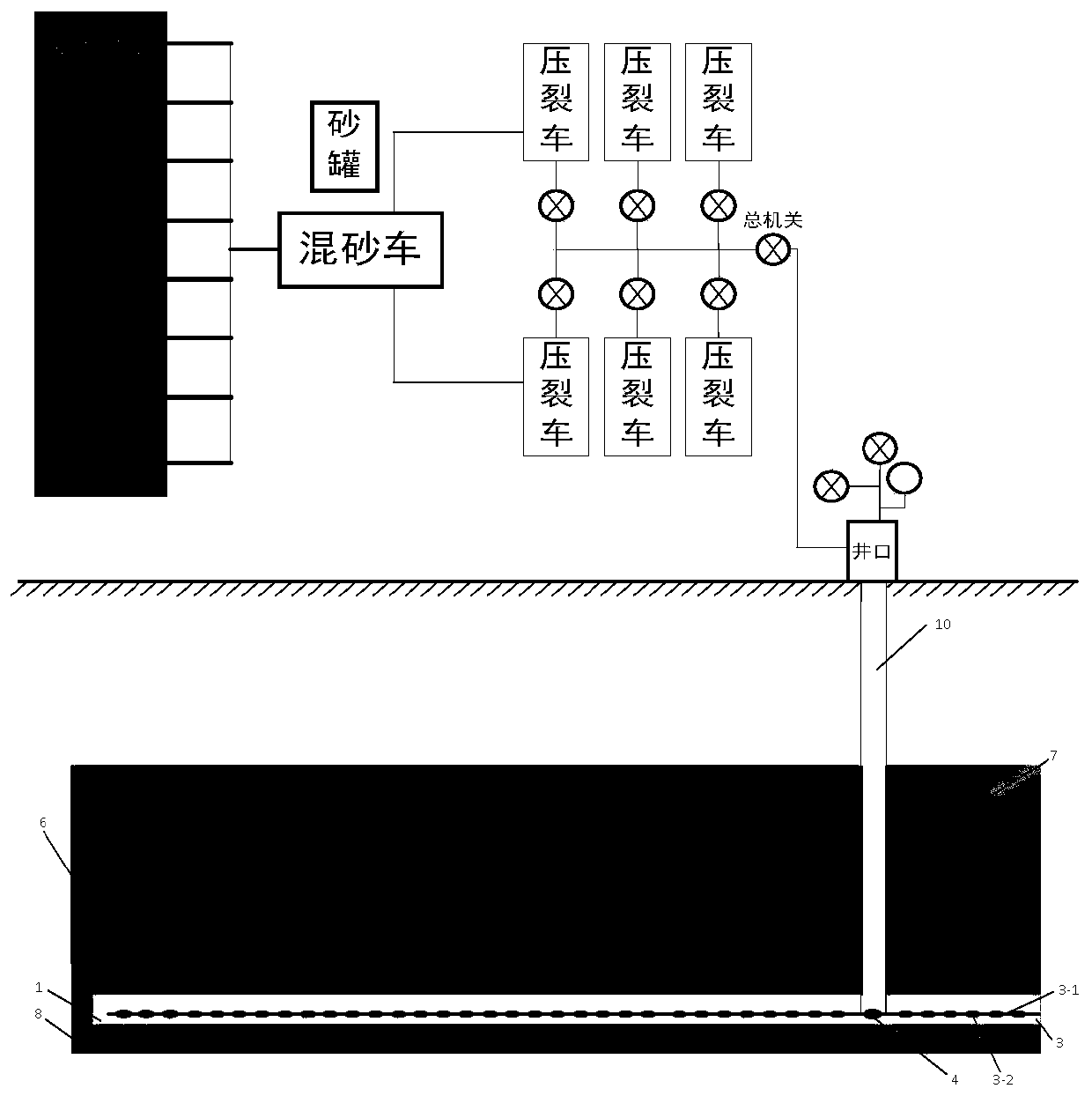

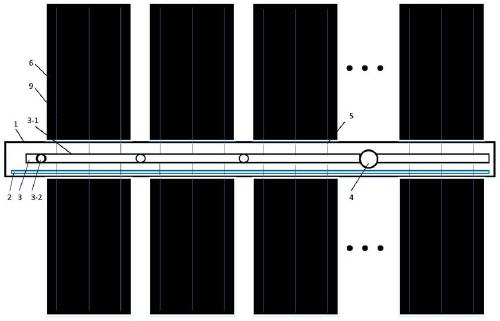

[0033] The high-efficiency gas drainage method in the upper and lower joint fracturing areas of the broken soft low permeability coal seam of the present invention may include the following steps:

[0034] Step 1: Determine the gas drainage target area, form the mining area roadway and the operation roadway 1, and can meet the requirements of the long borehole 9 drilling operation and fracturing construction operation.

[0035] Specifically, in order to meet the requirements of long borehole 9 drilling operations and fracturing operations, the working roadway should generally meet the width of 5m and the height of 4m.

[0036] Step 2: Construct multiple sets of coal seam roof or floor long boreholes 9 to cover the entire gas extraction area.

[0037] Specifically, precise geo-steering technology is used to control the relatively stable dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com