Power positioning jet-flow spraying type ditcher

A technology for dynamic positioning and trenching machines, which is applied to mechanically driven excavators/dredgers, earthmoving machines/shovels, construction, etc., can solve the problems of low equipment power, large pipeline negative pressure and high cost, and achieve Fast trenching speed, improve efficiency, and enhance the effect of water jet cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in combination with specific embodiments.

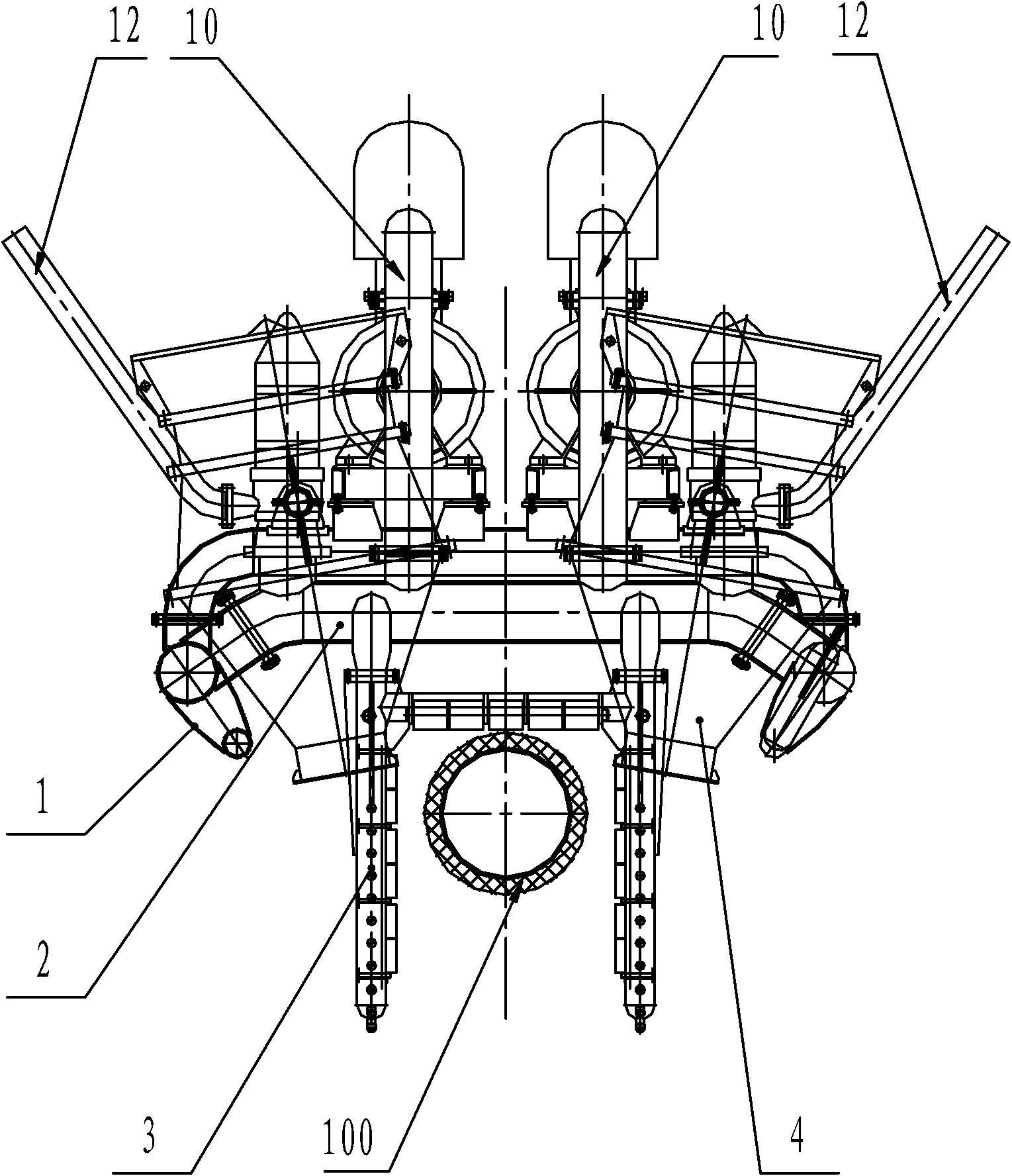

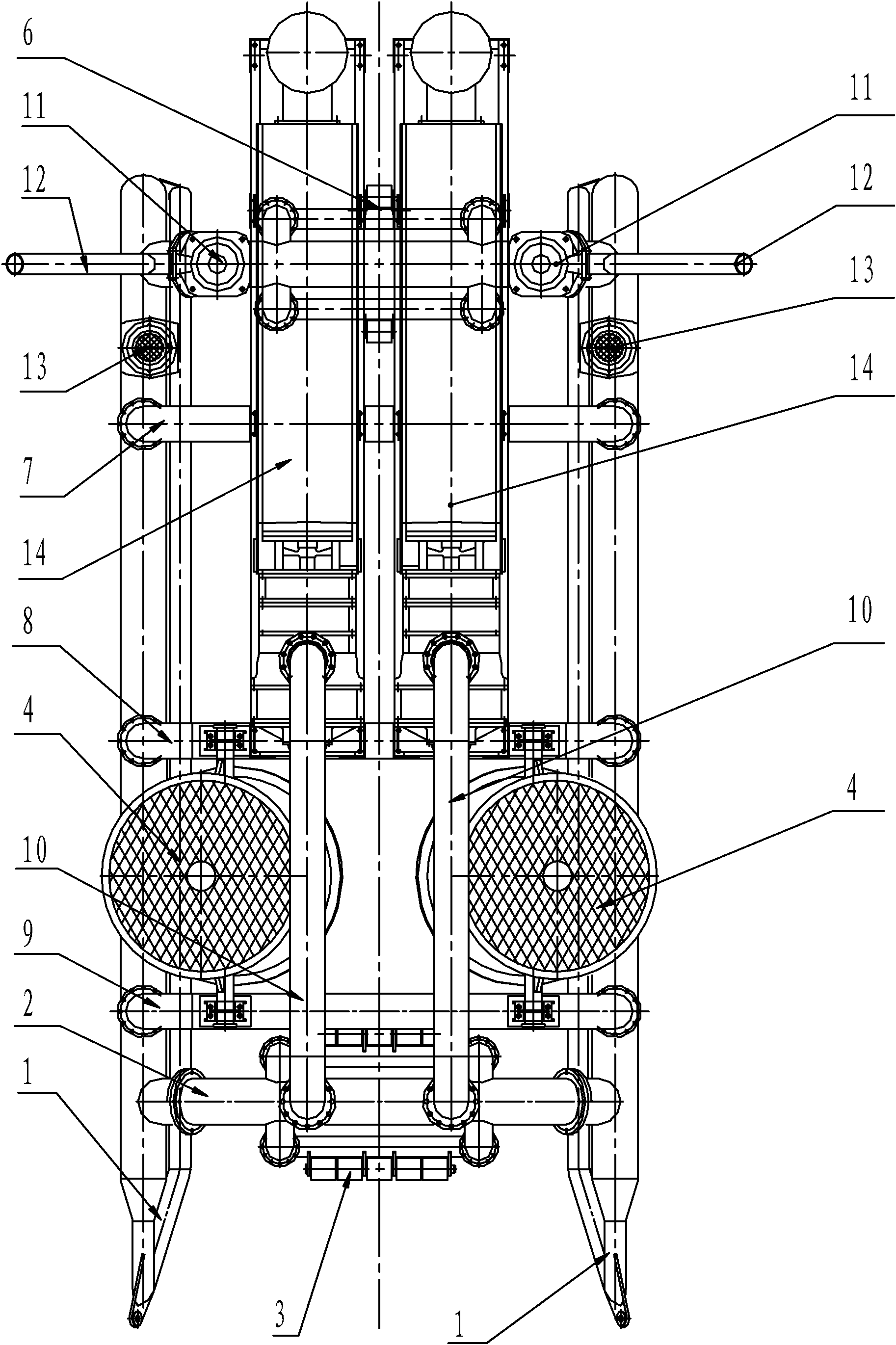

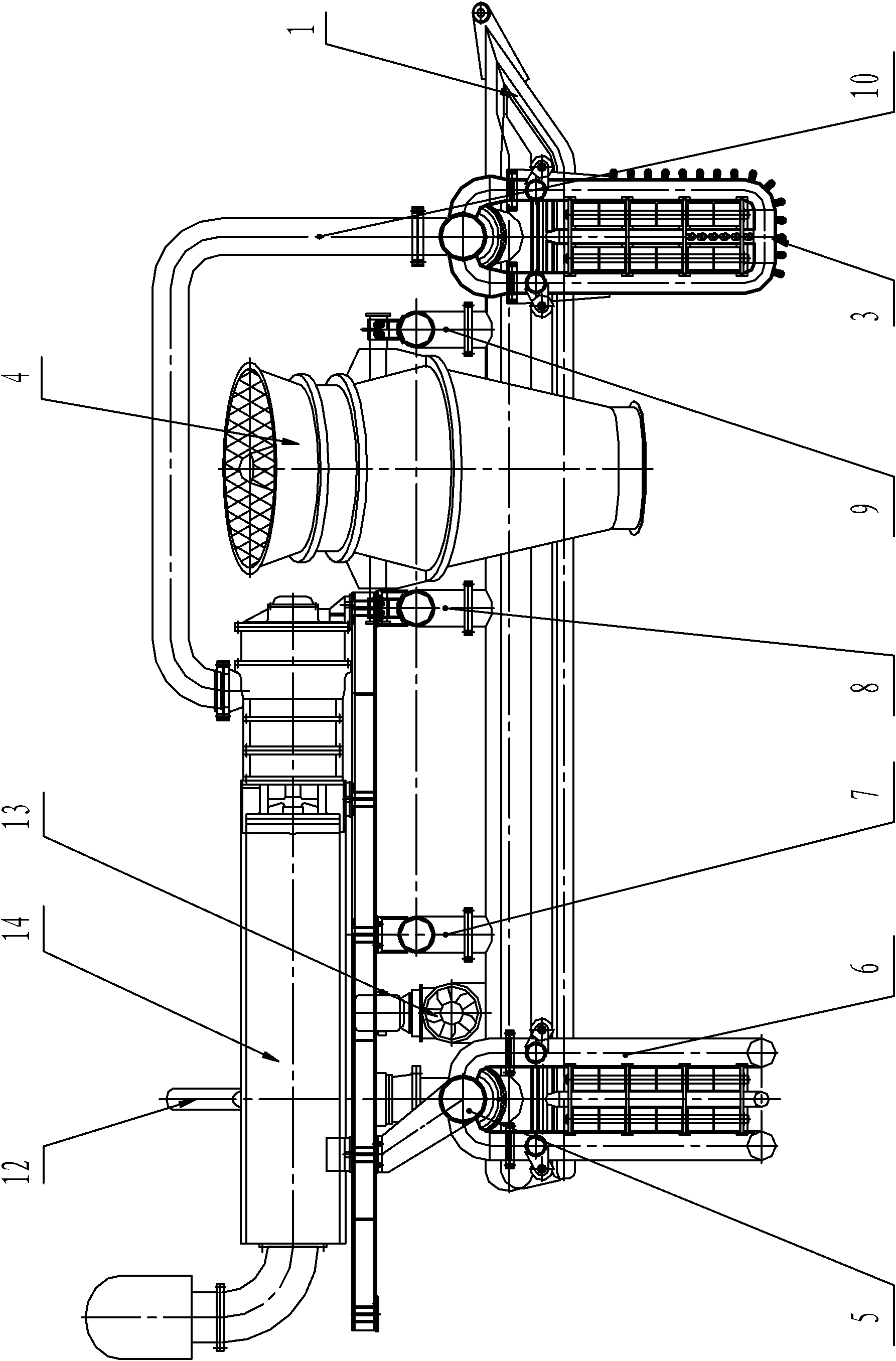

[0036] Such as figure 1 , figure 2 and image 3 As shown, a dynamic positioning jet jetting type trenching machine of the present invention includes a main frame, and the main frame is composed of a front main beam 2 and a rear main beam 5 and is arranged around the front main beam 2 and the rear main beam 5. The skids at both ends constitute, the front sub-beam 9, the middle sub-beam 8 and the tail sub-beam 7, which are all fixed with the skids at both ends, are arranged between the front main beam 2 and the rear main beam 5, that is, the main frame includes There are five beams, all of which are connected to the skids at the left and right ends with bolts through the round flange at the lower part. All are fixed with a thruster 13 in place, and the power supply is respectively transmitted underwater by the low-voltage generator set 62 on board by the power c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com