Ground grooving machine for monitoring equipment manufacturing enterprise modifying

A technology of measurement and control equipment and grooving machine, which is applied in the direction of manufacturing tools, stone processing equipment, working accessories, etc., to achieve the effects of convenient operation, improved grooving efficiency and better chisel effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

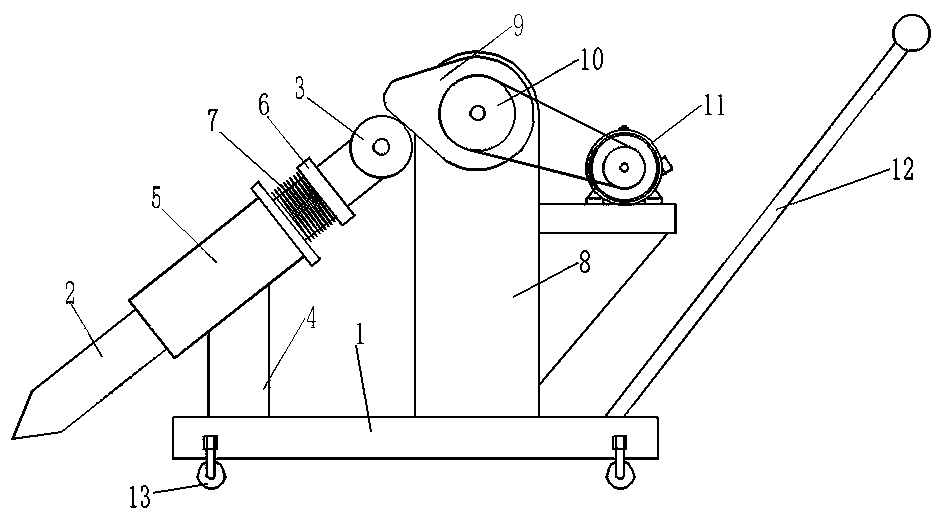

[0008] figure 1 Middle: chassis 1, chisel 2, roller 3, first column 4, guide sleeve 5, fixed plate 6, spring 7, second column 8, cam 9, pulley 10, motor 11, push rod 12, caster 13.

[0009] The ground slotting machine for the transformation of measurement and control equipment manufacturing enterprises includes a chassis 1 and a chisel 2. The chisel 2 is a columnar body. One end of the chisel 2 is a tip. The chassis 1 is fixedly connected with a guide sleeve 5 through the first column 4, the inner wall of the guide sleeve 5 is connected with the cylindrical surface of the chisel 2, and the guide sleeve 5 can slide back and forth along the inner wall of the chisel 5, so The guide sleeve 5 guides the excavation of the chisel. The included angle between the chisel 2 and the ground is 30-45°, and the chisel 2 excavates towards the inclined direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com