Horizontal goniometer for guide beam

A technology of level measuring instrument and guide beam, applied in height/level measurement, measuring device, measuring inclination, etc., can solve the problem of low adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

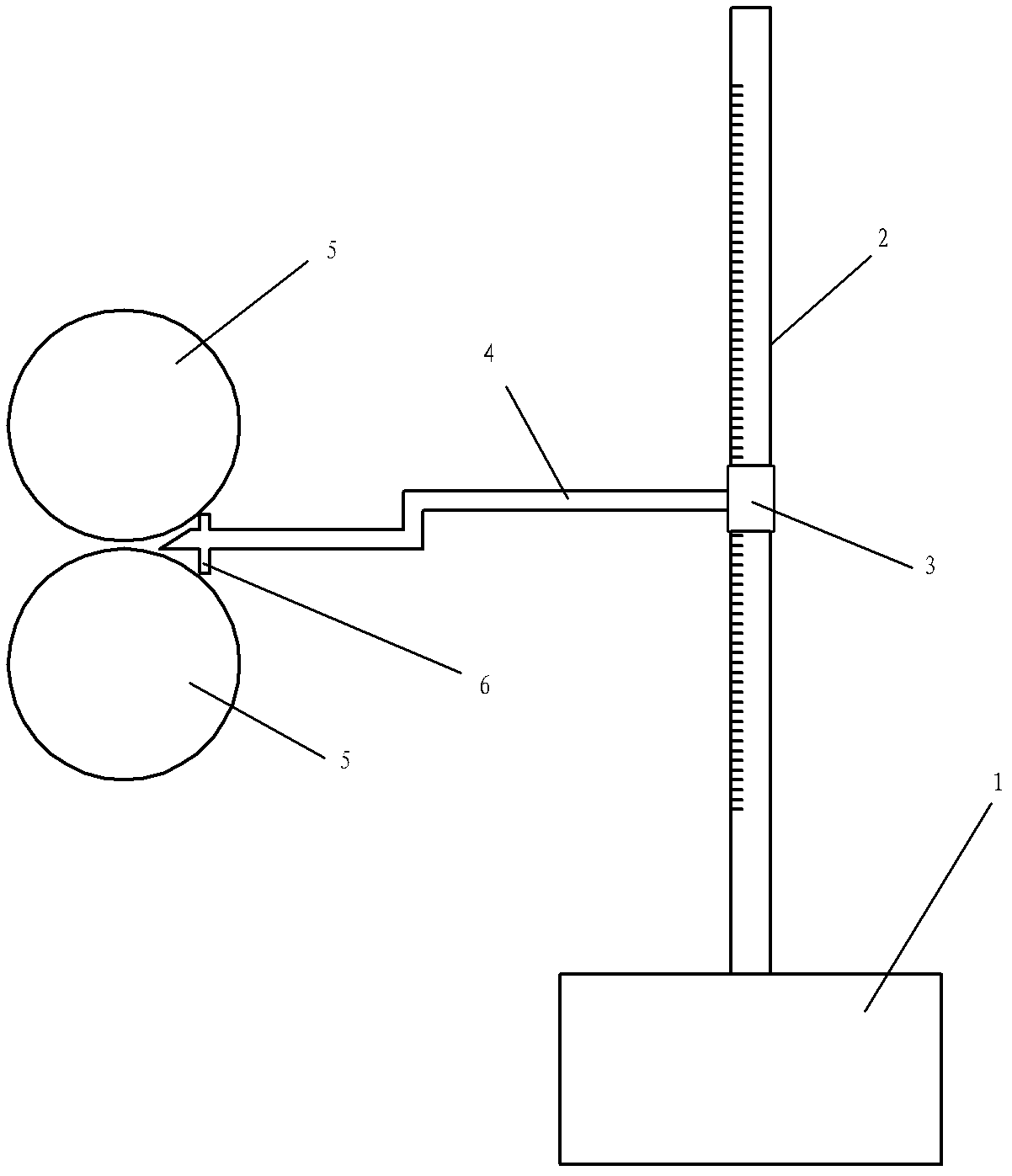

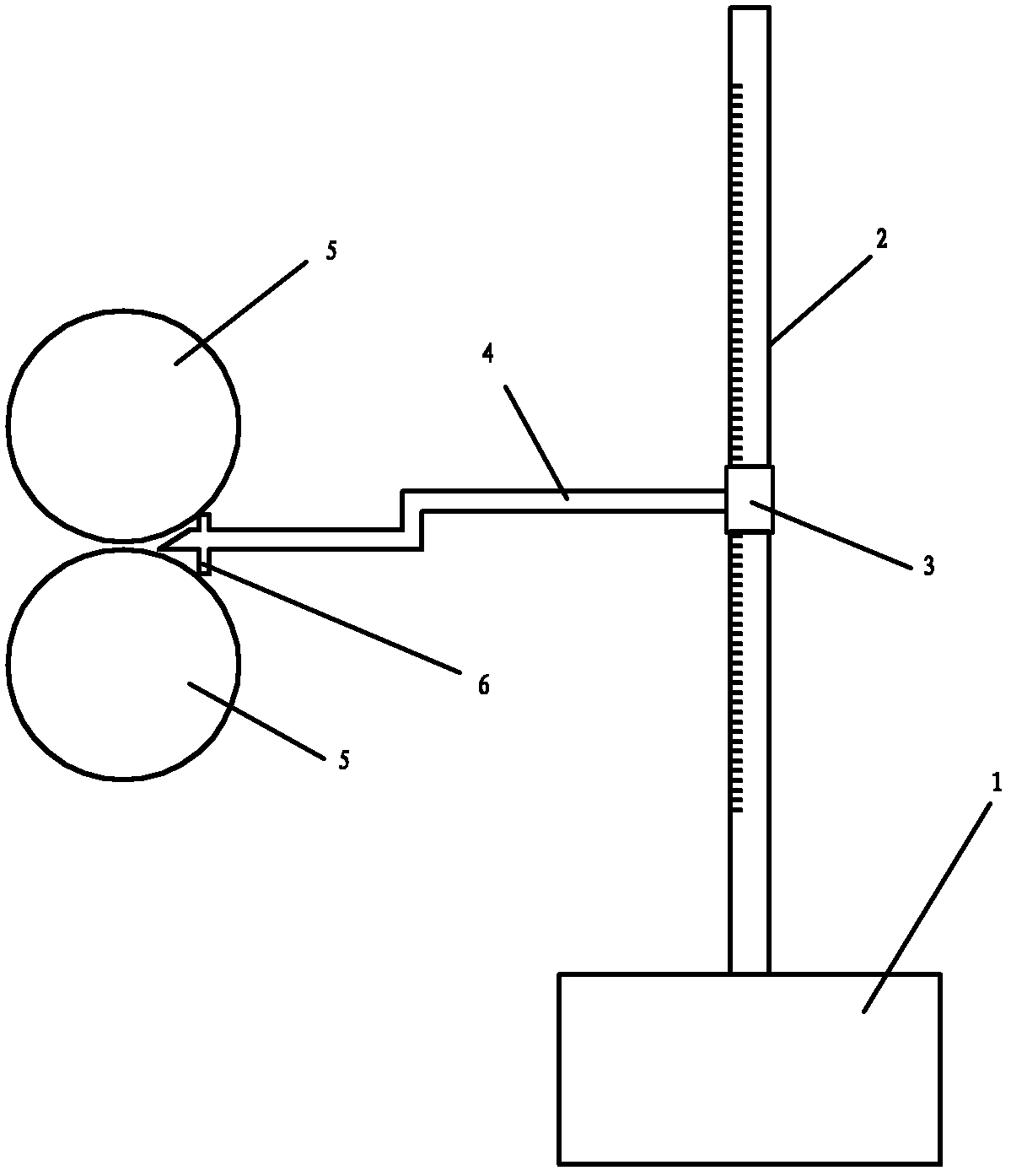

[0006] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. This embodiment includes a base 1, a height gauge 2, a vernier 3 and a probe 4. The height gauge 2 arranged in the vertical direction is fixed on the base 1, and the vernier 3 that can slide and position along the body of the height gauge 2 is set On the body of the height gauge 2, one end of the probe 4 is fixed on the vernier 3, and the length direction of the probe 4 is arranged horizontally. The base 1, the height gauge 2, and the vernier scale 3 can select existing height micrometers.

specific Embodiment approach 2

[0007] Specific implementation mode two: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that it also includes a positioning rod 6, which is fixed on the other end of the probe 4, and the distance between the ends of the positioning rod 6 and the probe 4 is equal. Because the guide beam 5 is a cylinder, when the probe 4 is stretched to the junction of the two guide beams 5, the positioning rod 6 is used to push against the cylindrical surface of a guide beam 5 respectively, which can ensure that the probe 4 is connected to the two guide beams 5. The distance between the guide beams 5 is equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com