Stamping automatic plate alignment table

A technology for centering table and sheet metal, used in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of long centering time, can not meet the requirements of blank centering speed, etc., to improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

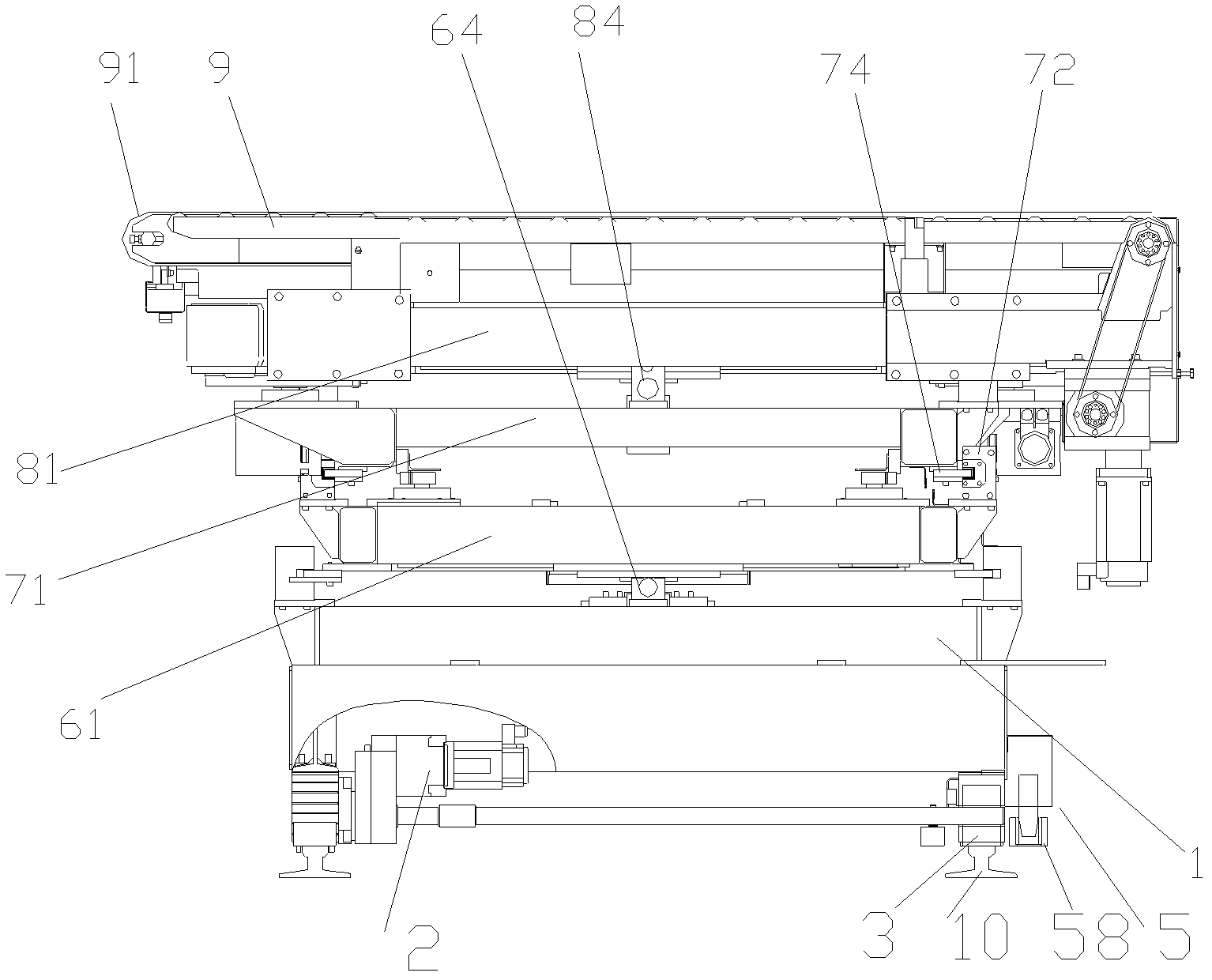

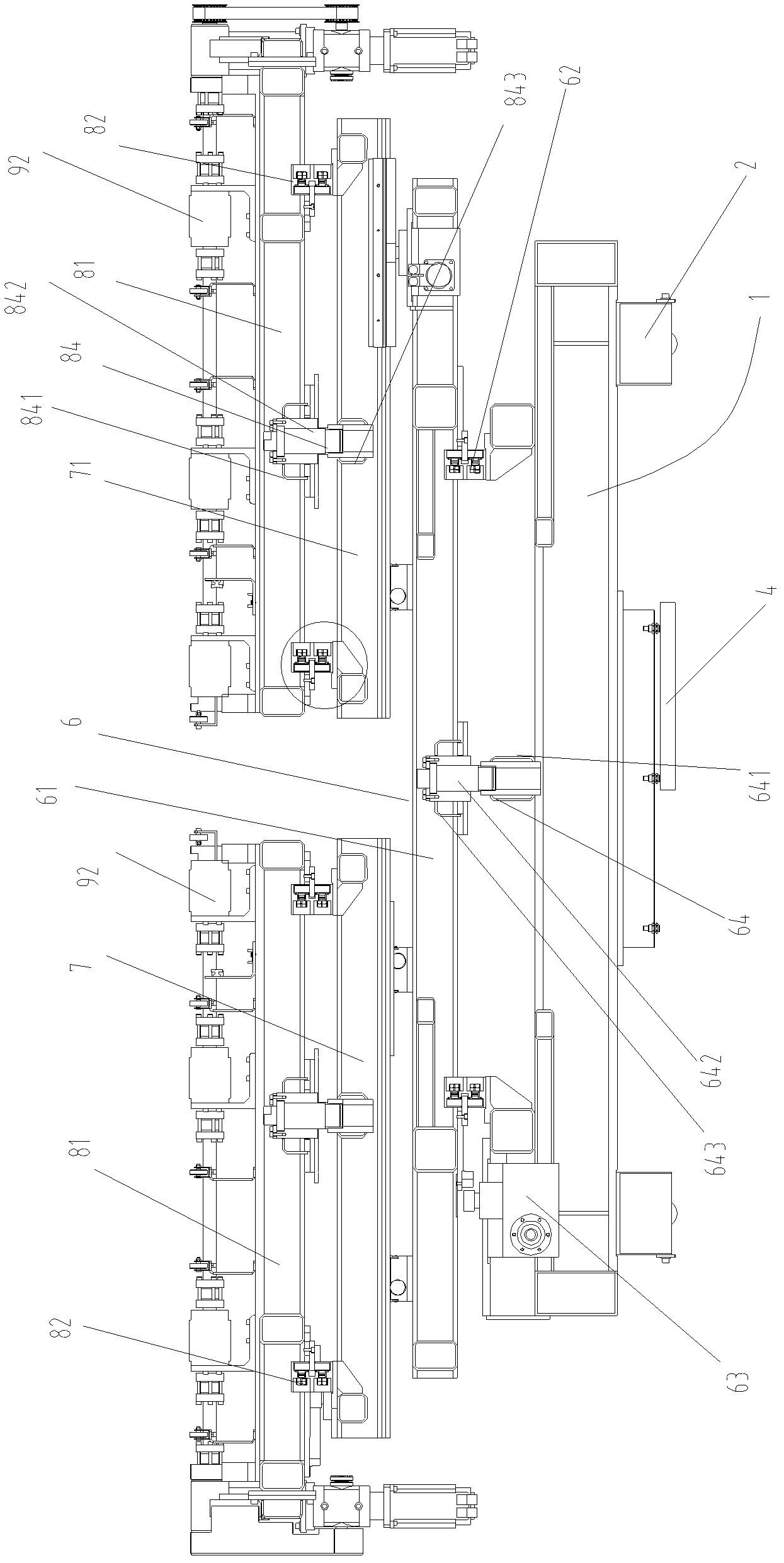

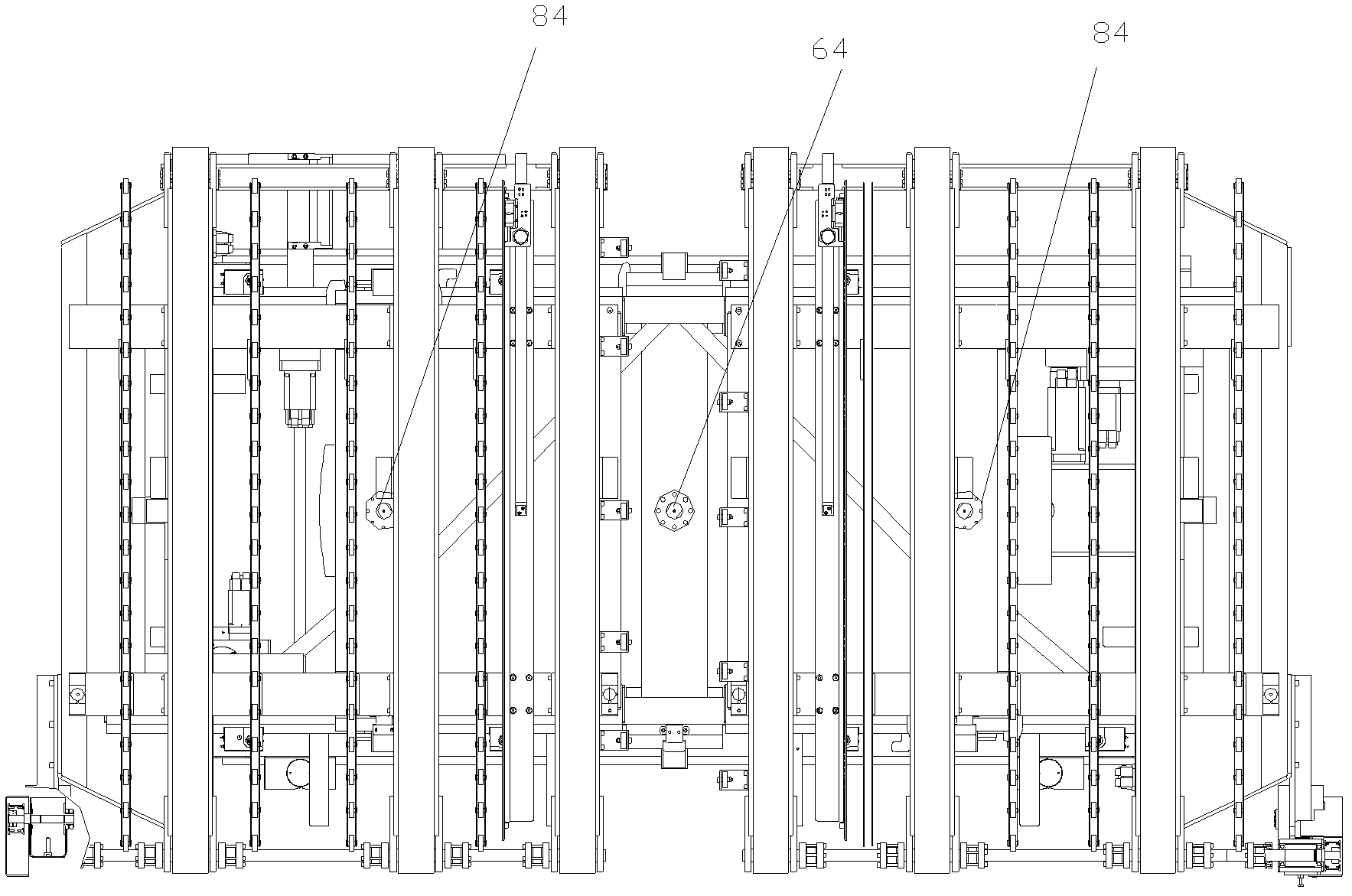

[0072] Such as Figure 1-3 As shown, the sheet metal centering platform shown in the present invention includes a frame base 1 composed of profiles, and a traveling mechanism is arranged under the frame base 1, wherein the traveling mechanism includes a servo motor 2, a supporting and traveling traveling wheel 3 and a proximity switch 4. The top of the frame base 1 is provided with an integral rotating frame 6, the top of the integral rotating frame 6 is provided with two parts of the horizontal moving frame 7, and the top of the two parts of the horizontal moving frame 7 is respectively provided with a single rotating frame 8, and the two parts are single An electromagnetic sheet material conveyor belt 91 and supporting rollers 92 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com