Method for extracting metal zinc powder with different purposes from zinc dross

A technology for zinc scum and metal zinc, applied in the field of metal zinc powder, can solve problems such as unrealized industrialization, and achieve the effects of protecting occupational health, saving production costs, and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

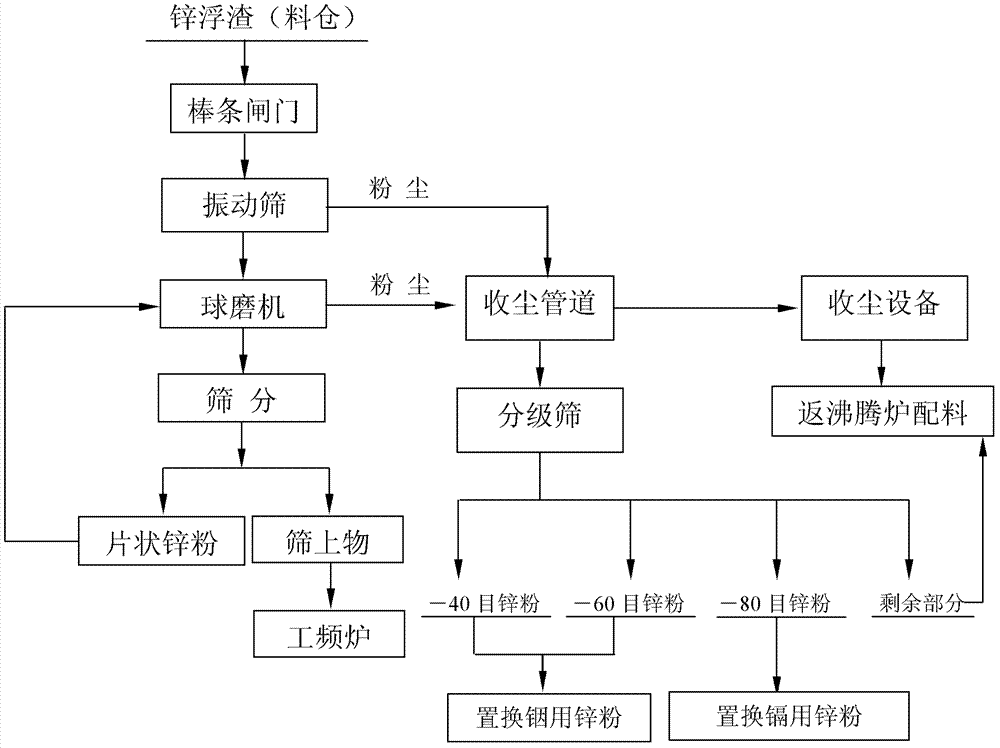

Image

Examples

Embodiment 1

[0022] Take 200kg of zinc scum (the main chemical composition is: Zn is 84.48%, F is 0.017%, Cl is 0.079%), the particle size range is ≤3mm, and it is naturally cooled to room temperature. The cooled zinc scum is continuously fed Slowly pour into the silo. 99-100% of the zinc scum in the silo passes through the bar screen and enters the closed linear vibrating screen. The coarse particles screened by the vibrating screen enter the ball mill. All are imported into the dust collection pipeline. After the coarse particles are firstly ground by the ball mill and screened by the grid sieve once, the part under the sieve is returned to the ball mill for the second crushing, and the part under the second sieve is returned to the ball mill for the third crushing, according to crushing----screening ----Return material for cycle operation. All the sieve parts are returned to the zinc smelting process to use the power frequency furnace for remelting and recycling. All the dust generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com