Patents

Literature

33results about How to "Protect occupational health" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

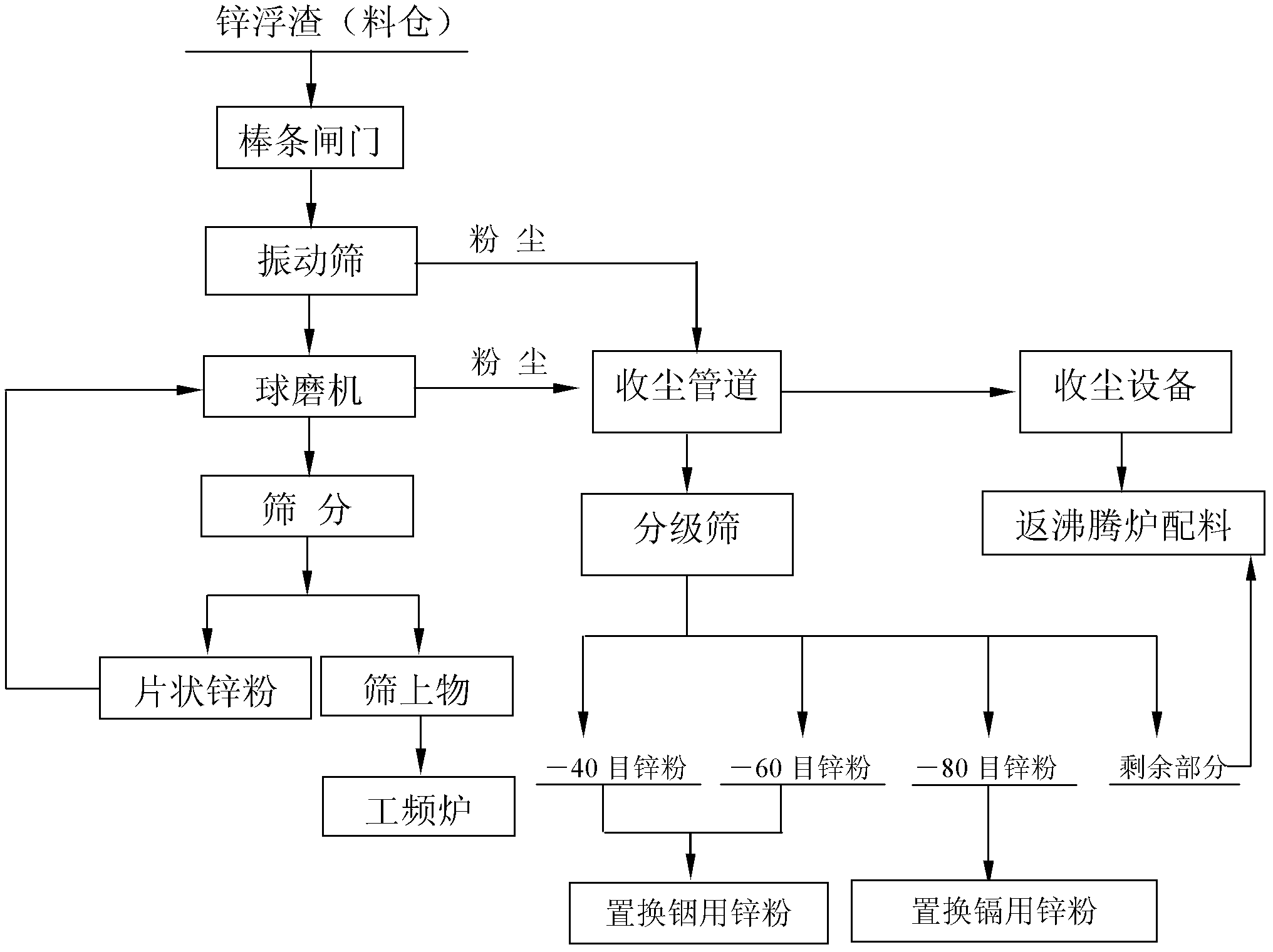

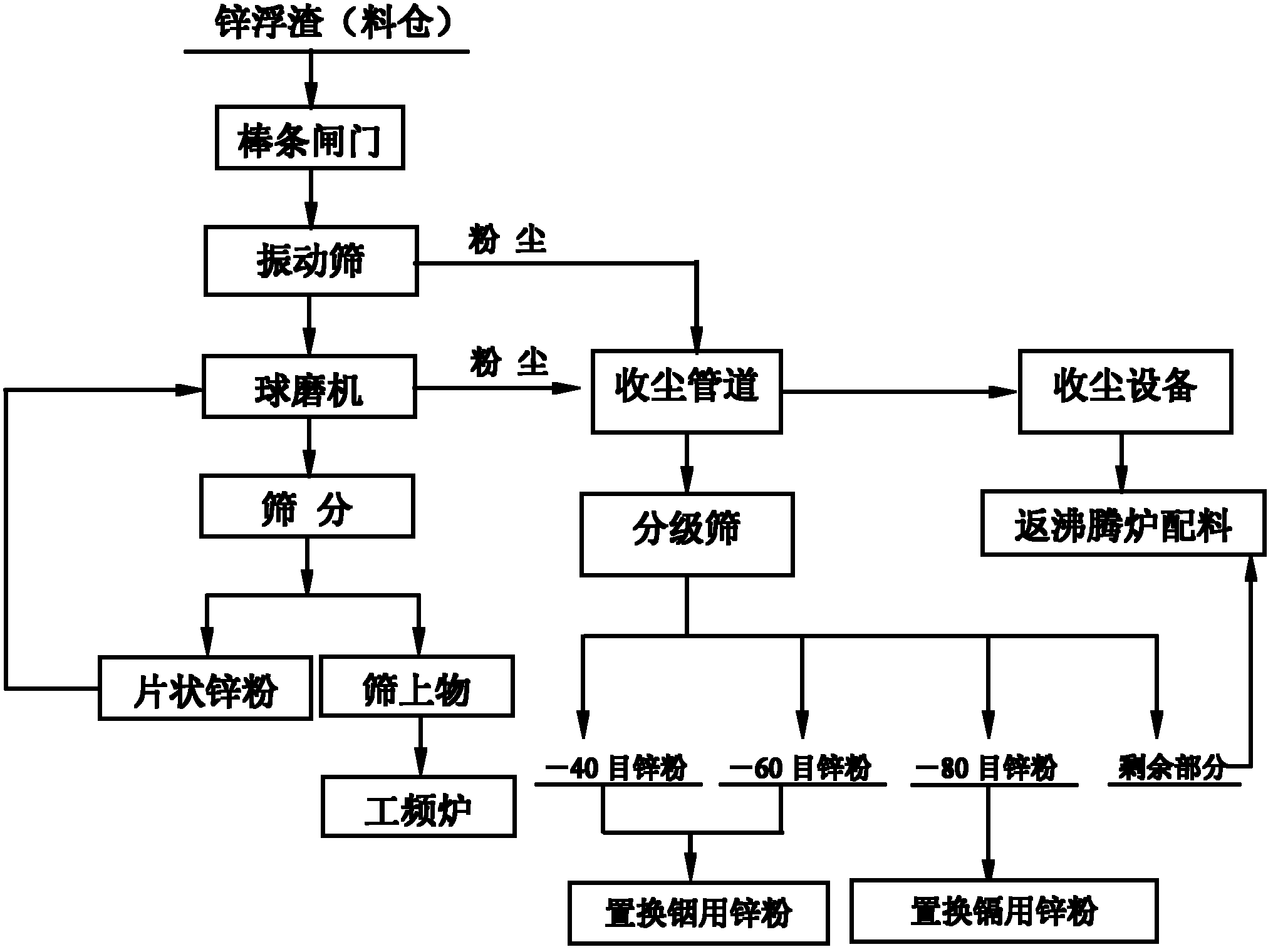

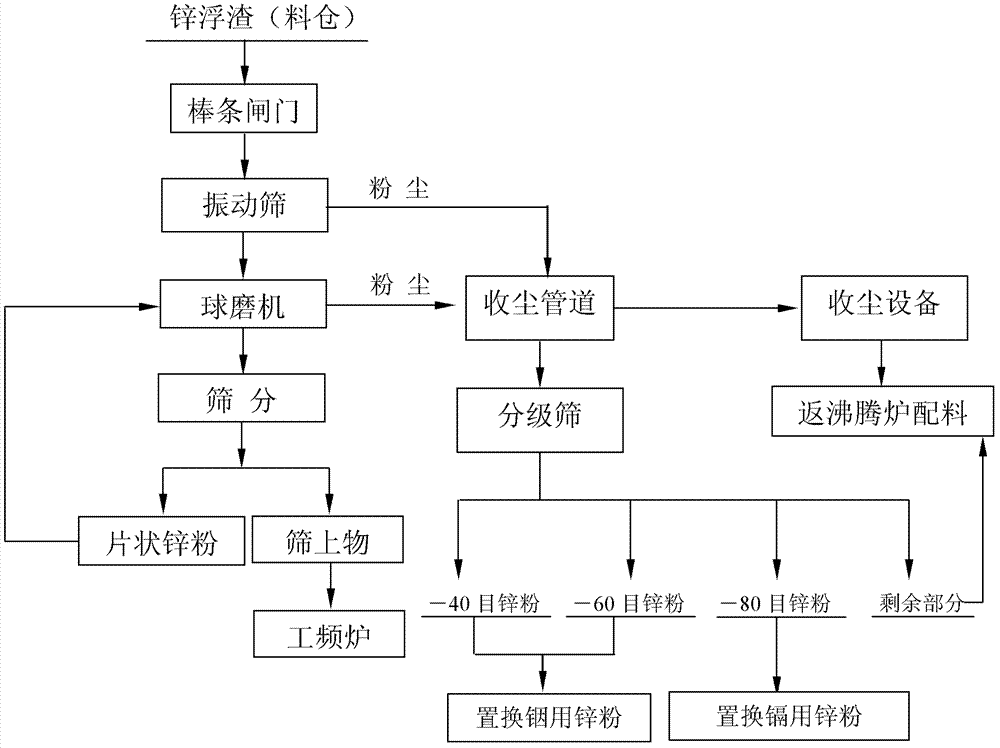

Method for extracting metal zinc powder with different purposes from zinc dross

ActiveCN102423803AReduce manufacturing costAlleviate the problem of high ionsProcess efficiency improvementHydrometallurgyZinc smelting

The invention relates to a method for extracting metal zinc powder with different purposes from zinc dross, in particular to a method for treating zinc dross by adopting ore grinding and dust collection equipment and metallurgical equipment as well as a metallurgical process to obtain metal zinc powder with different particle sizes and different purposes, which belongs to the cross field of the ore grinding and metallurgy technology. The method comprises the following steps: vibrating and crushing the zinc dross, and crushing and screening by using a ball grinding mill; carrying out tertiary screening on collected dust and powder dust of each pipeline; and collecting the dust by using the dust collection equipment. The invention has the advantages that the powder dust is not discharged torealize environmental friendliness; and three kinds of metal zinc powder and two kinds of residues in a return zinc smelting process are obtained only by adopting a physical crushing method, so that the recovery rate of zinc is improved, and the highly-efficient separation and the zero discharge of valuable elements are realized. The invention solves the problem of large quantity of Cl ions generated in a zinc hydrometallurgy process and simultaneously realizes the effects that the whole process is closed together with products, the zinc content of the various zinc powder is more than or equal to 98 percent, and the total recovery rate of the zinc is 99.5-100 percent.

Owner:云南云铜锌业股份有限公司

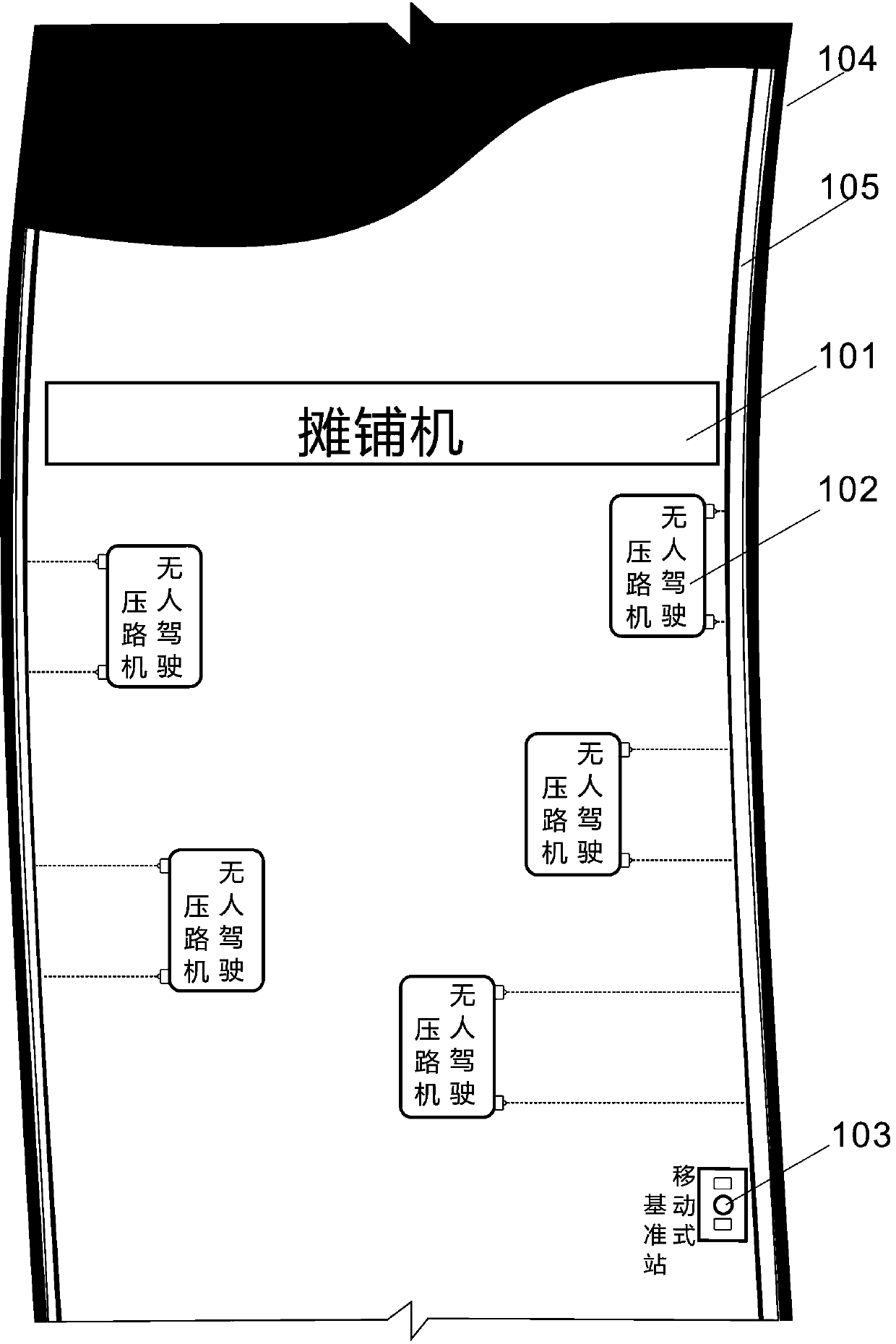

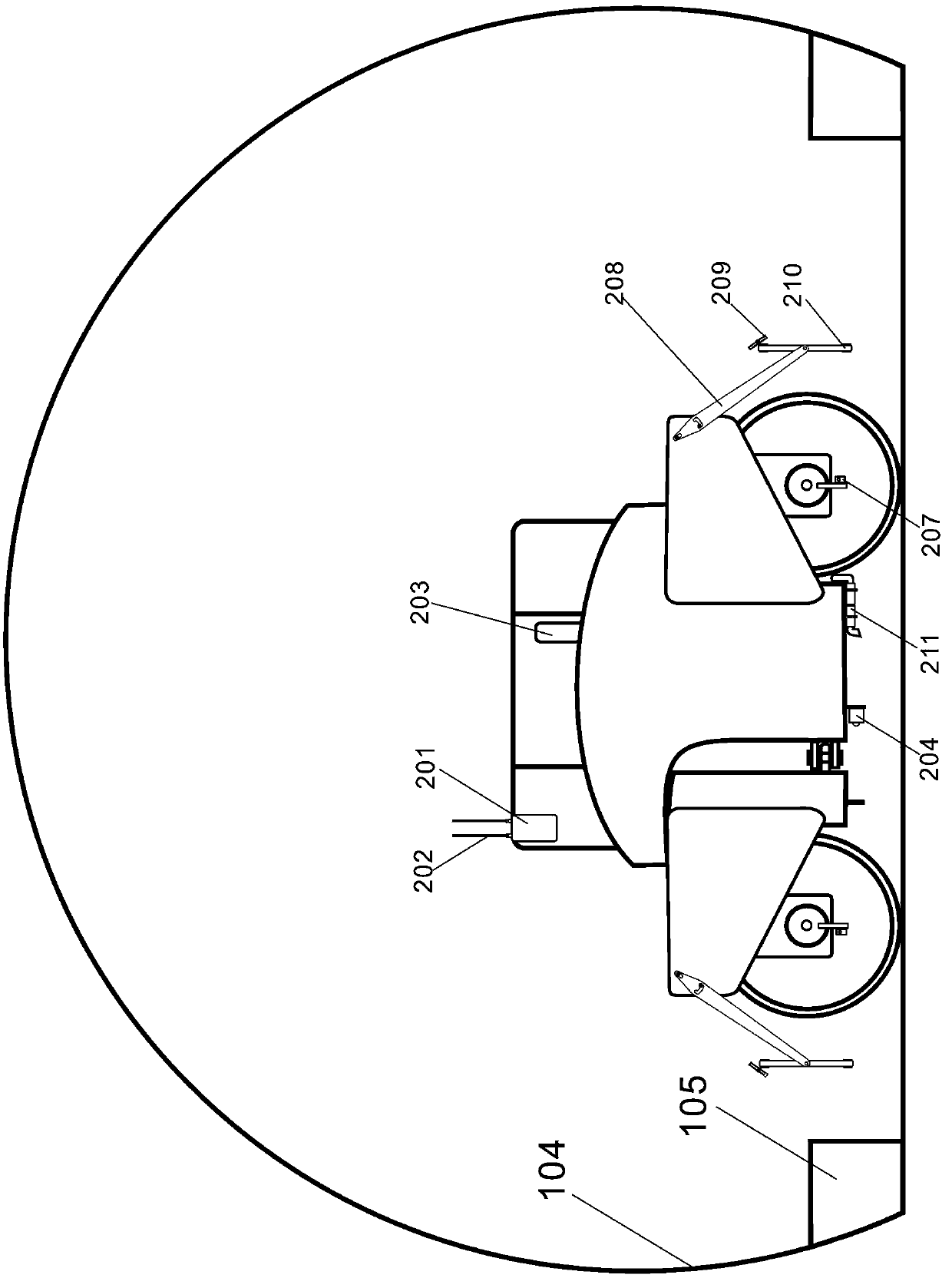

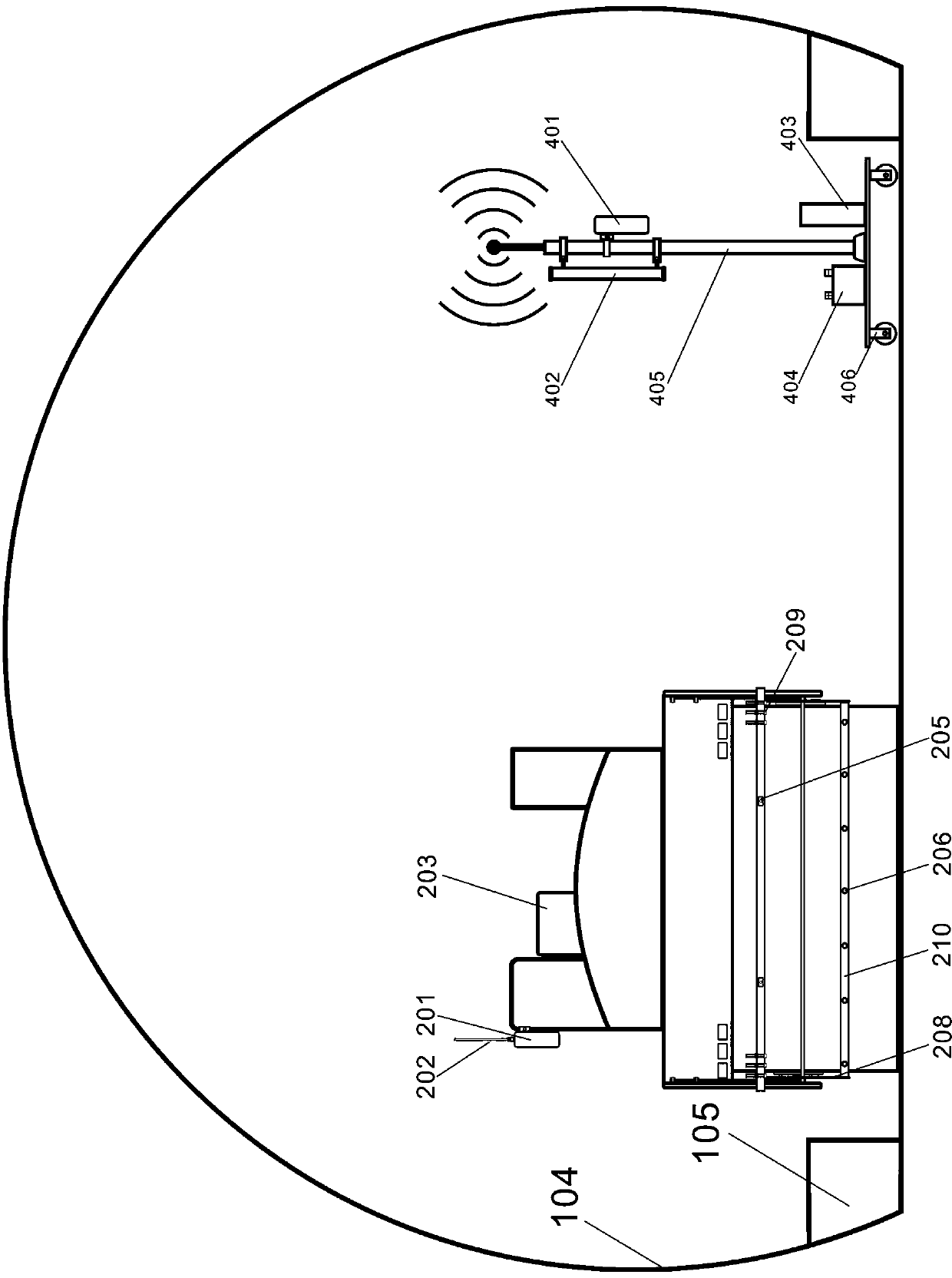

Unmanned road roller rolling system in tunnel without satellite signal

PendingCN110258260ARealize unmanned rolling operationAvoid sufferingRoads maintainenceLaser rangingMicrowave

The invention discloses an unmanned road roller rolling system in a tunnel without a satellite signal. The unmanned road roller rolling system in the tunnel without the satellite signal is characterized in that an unmanned road roller group composed of a plurality of road rollers, a path planning system arranged on a paver, and a mobile reference station form the unmanned road roller rolling system in the tunnel without the satellite signal; lateral laser distance measuring sensors are laterally arranged at the positions of the left side and the right side in front and back of a vehicle body of each road roller in a manner of forming a 90-degree angle with a running direction separately; the sidewall of a drainage ditch in the tunnel is taken as a reference substance, distances between vehicle wheels of each road roller and the sidewall of the drainage ditch are tested through the laser distance measuring sensors arranged on the road roller to set the running track of each amplitude of the road roller; the running of each road roller is controlled through microwave communication, and operating personnel of the road roller are prevented from working under an environment of mixing emitted tail gas and a high-temperature asphalt mixture; and the advantages of effectively protecting the occupational health of the operating personnel of each road roller is realized, avoiding the harm of poisonous and harmful substances to human bodies, and ensuring the rolling quality for an asphalt road surface in the tunnel.

Owner:SICHUAN CHUANJIAO ROAD & BRIDGE +1

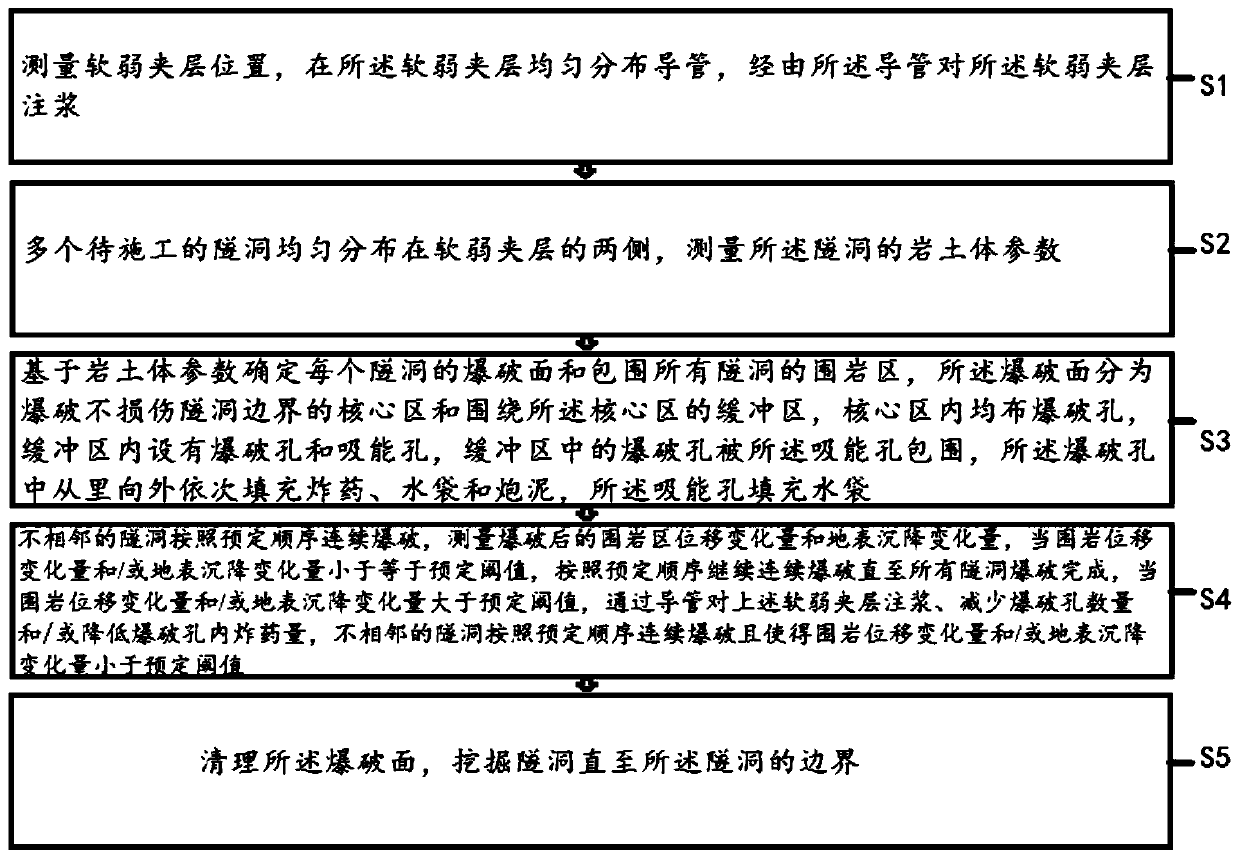

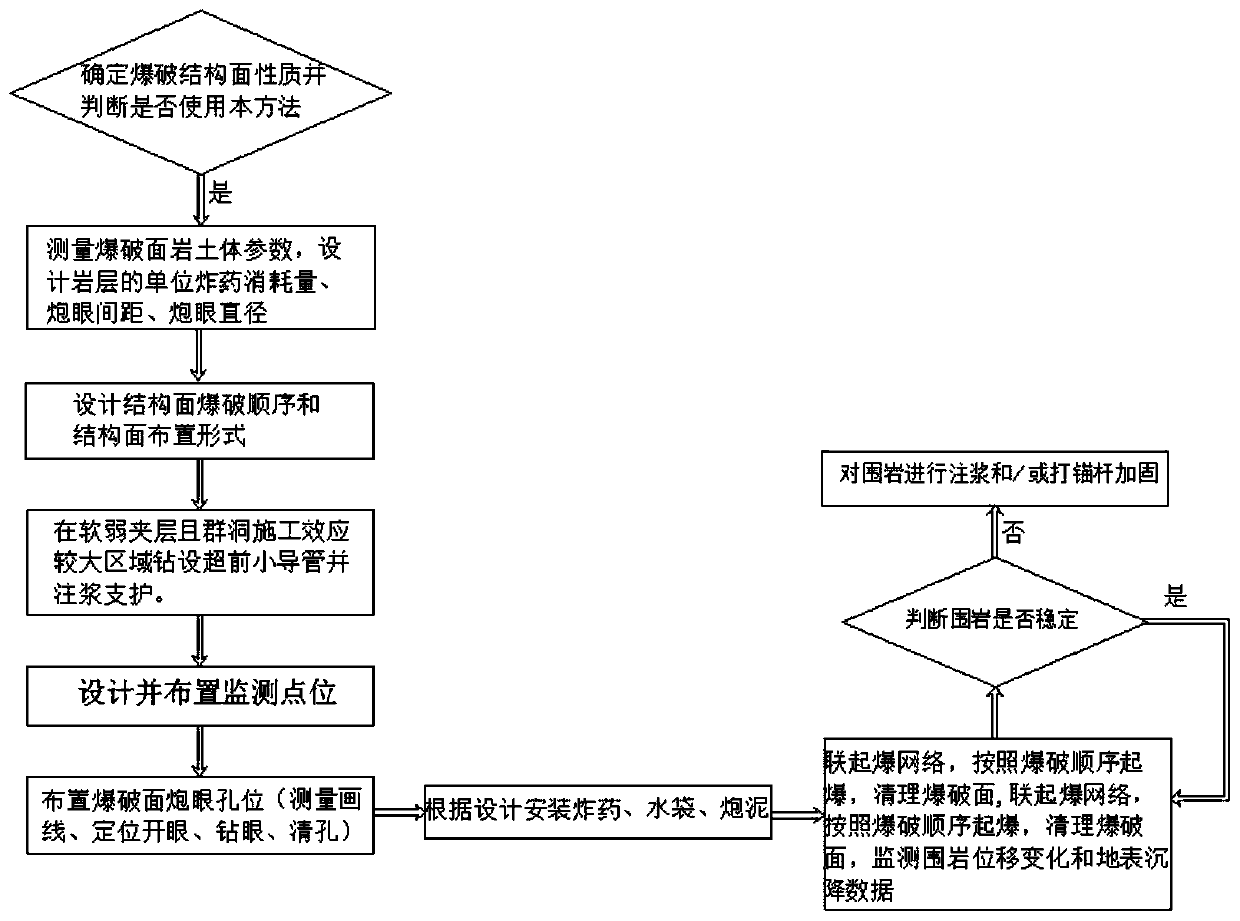

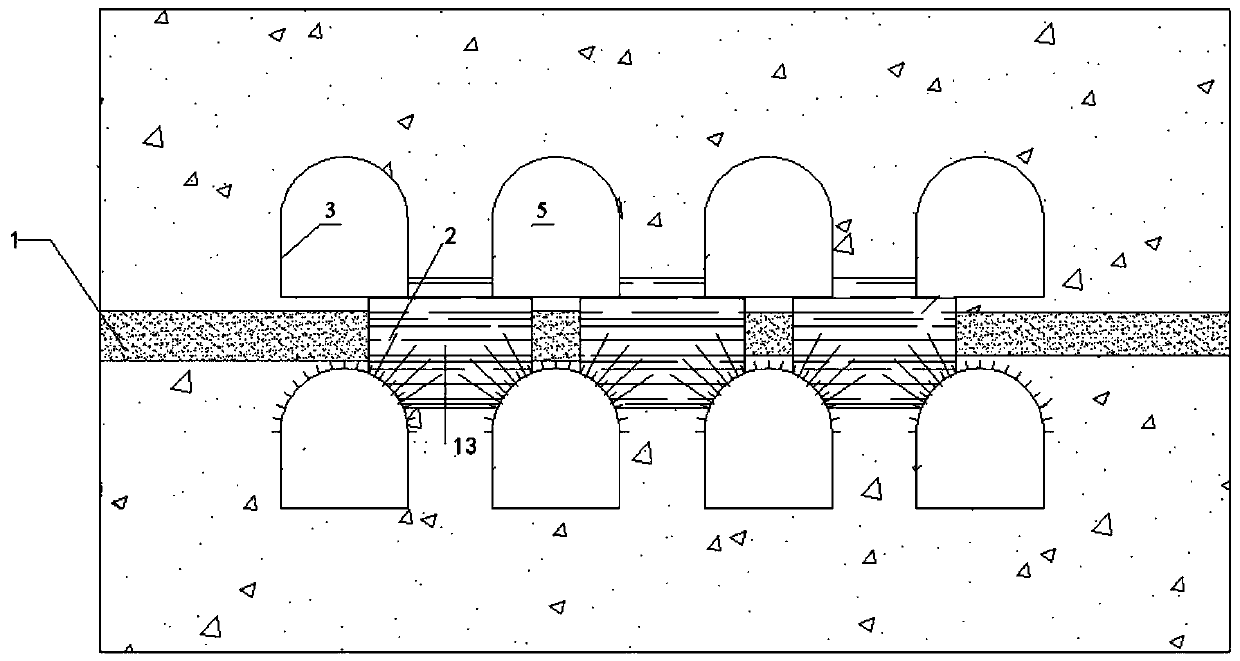

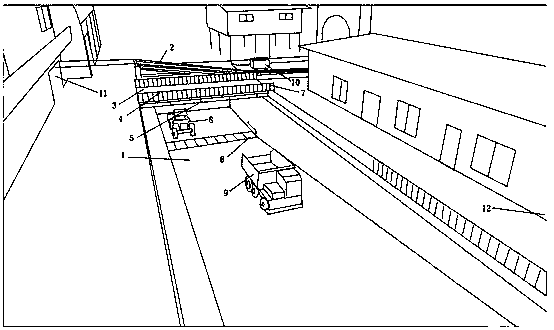

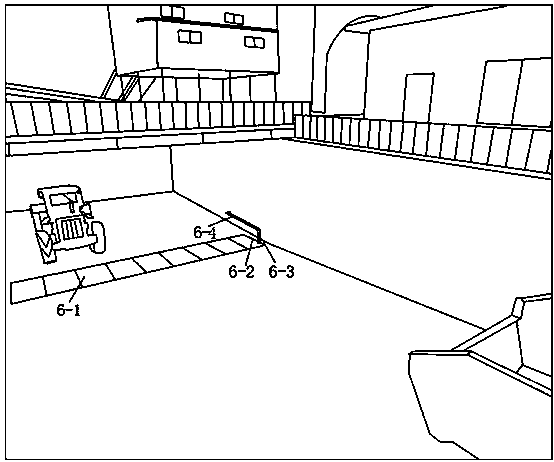

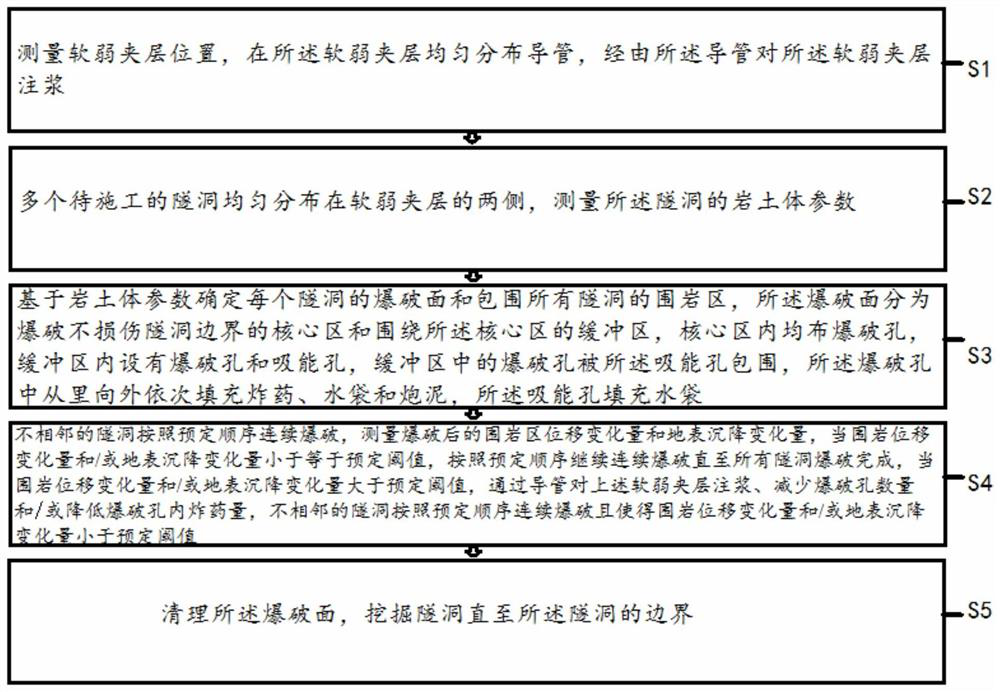

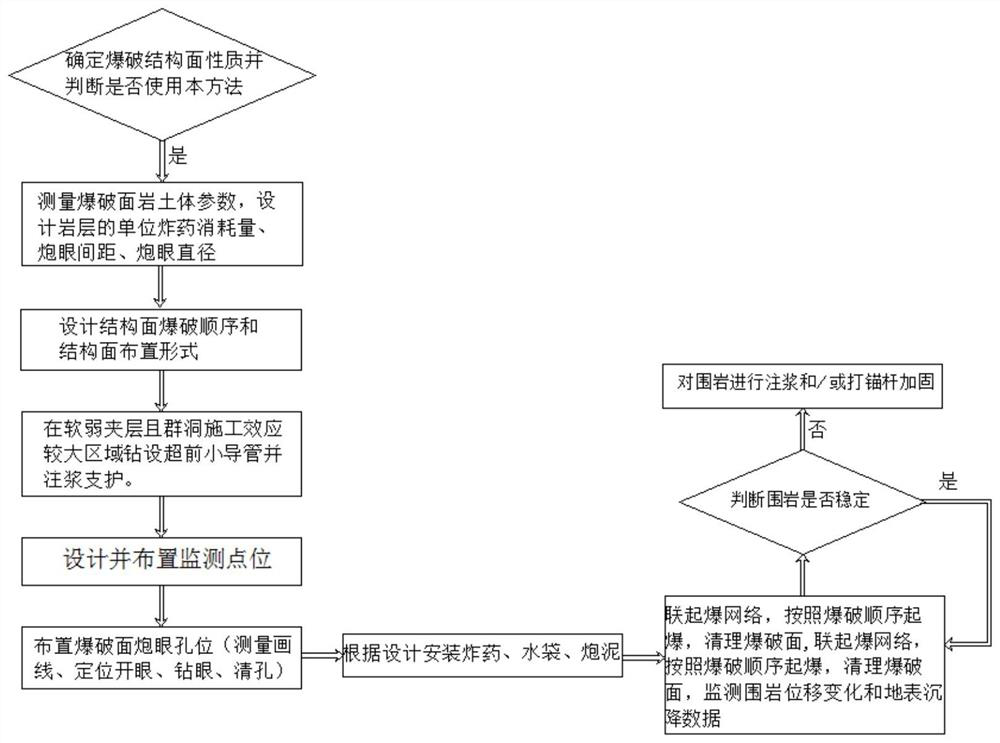

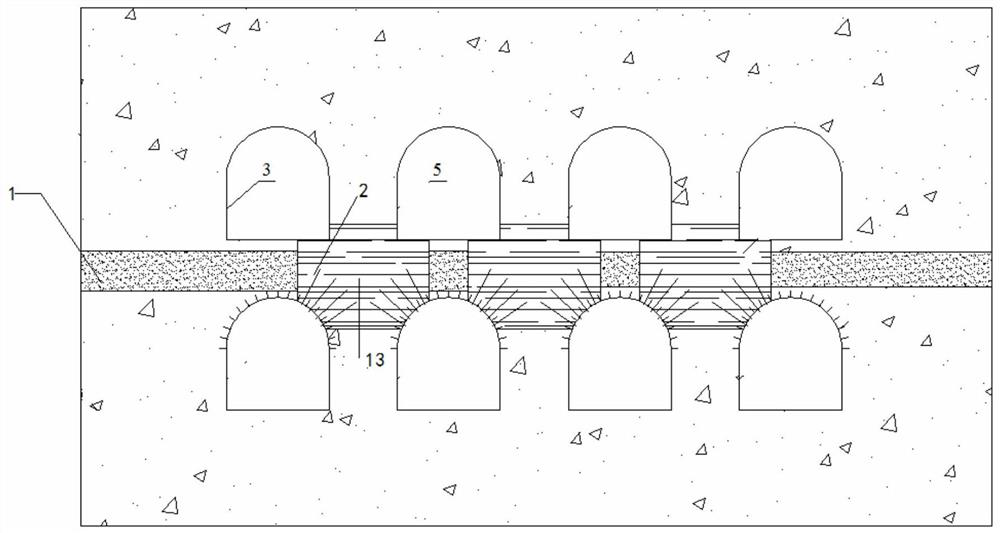

Multi-tunnel construction method based on soft interlayer

ActiveCN109737840AControl disturbanceConstruction safetyBlastingTunnelsEnergy absorptionEarth surface

The invention discloses a multi-tunnel construction method based on a soft interlayer. The method comprises the following steps of measuring the position of the soft interlayer, and uniformly distributing guide pipes on the soft interlayer, grouting the soft interlayer through the guide pipes to form a grouting area; uniformly distributing a plurality of tunnels to be constructed on the two sidesof the soft interlayer, measuring the rock and soil mass parameters of the tunnels;uniformly distributing blast holes in a core area, arranging blast holes and energy absorption holes in a buffer area, wherein the blast holes in the buffer area are surrounded by the energy absorption holes; continuously blasting the non-adjacent tunnels according to a preset sequence until all the tunnels are exploded, wherein when the displacement change amount of the surrounding rock and / or the change amount of the surface subsidence is larger than a preset threshold value, grouting is carried out on the soft interlayer through the guide pipes, the number of the blast holes is reduced and / or the amount of explosives in the blast holes is reduced, continuously blasting the non-adjacent tunnels according to a preset sequence, and enabling the displacement change amount of the surrounding rock and / or the surface settlement change amount is smaller than a preset threshold value.

Owner:中建华东投资有限公司 +2

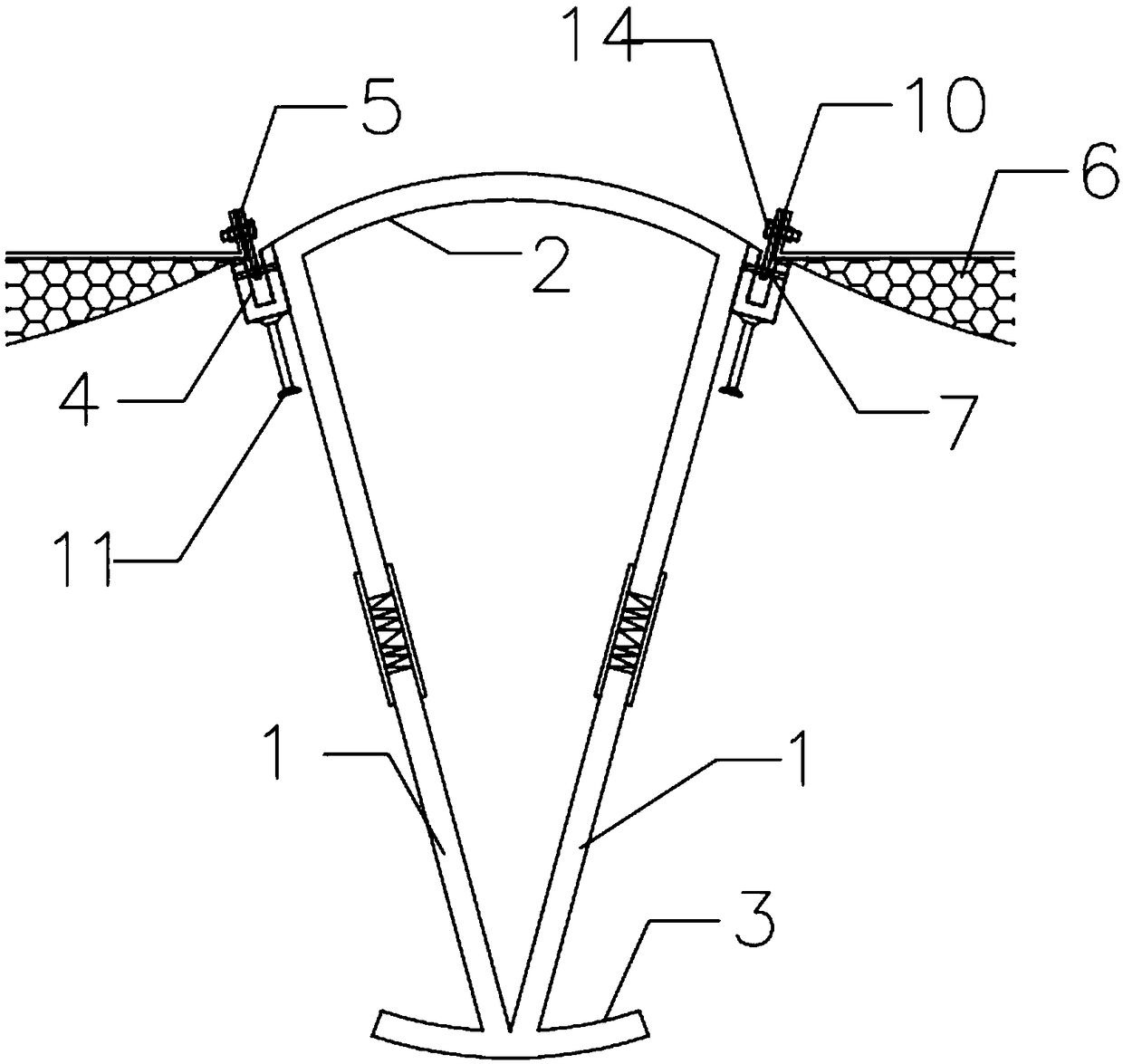

Foundation pit breast board supporting and sealing structure and construction method thereof

The invention discloses a pit breast board supporting and sealing structure and a construction method thereof. The pit breast board supporting and sealing structure comprises drilling injection piles,breast board anchoring and positioning devices and a breast board; the breast board anchoring and positioning devices are vertically fixed on a rebar cage at intervals; each breast board anchoring and positioning device comprise support brace rods, a large arc brace rod and a small arc brace rod; U-shaped grooves are fixed on two sides of the support brace rods; a steel plate sealing belt is arranged in each U-shaped groove; the breast board is provided with a body; two ends of the body are bent upwards and form bending edges; and the bending edges of the breast board are separately connectedto the steel plate sealing belts in the U-shaped grooves on the injection piles on the two sides and form a breast sealing edge jointly with the injection piles on the two sides. The earth-among-pilebreast board disclosed by the invention is convenient to assemble and disassemble and is easy to operate; the breast board can baffle soil and can also baffle water and prevent permeation; foundationpit supporting time can be shortened; on-site construction speed can be enhanced; besides, the tool-type breast board can be used repeatedly, so that cost is reduced; and the construction cost is lowered.

Owner:CHINA FIRST METALLURGICAL GROUP

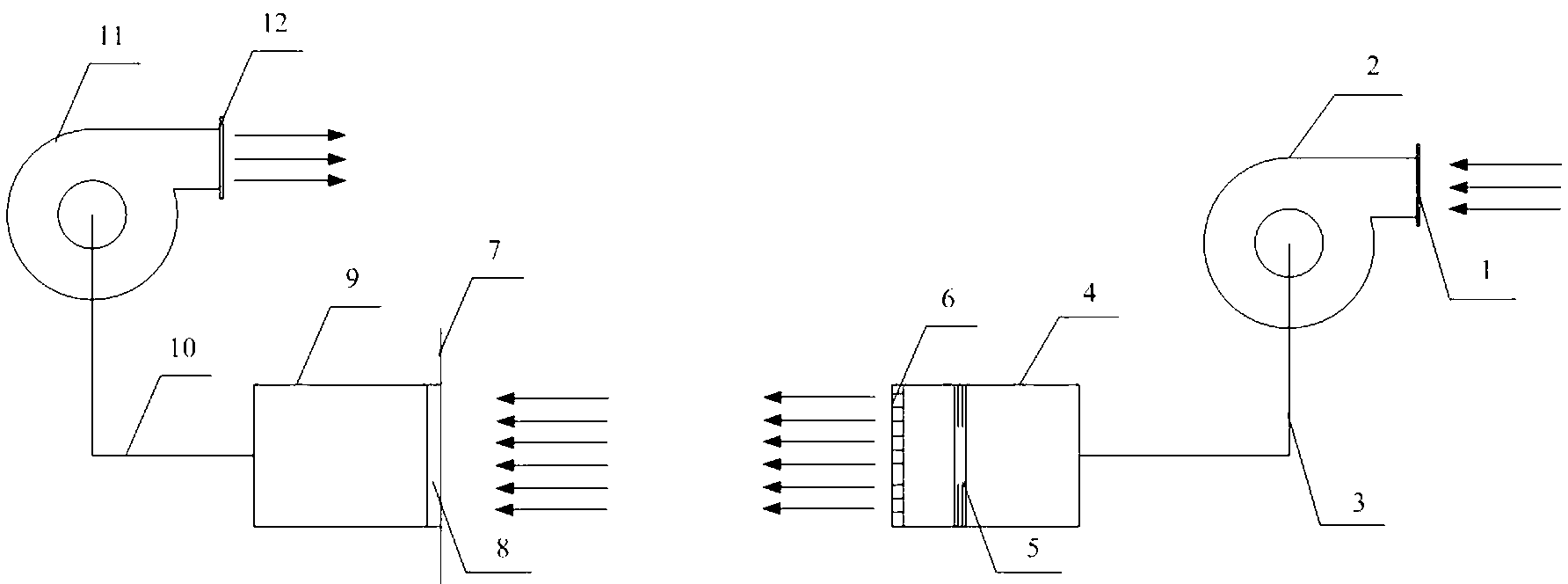

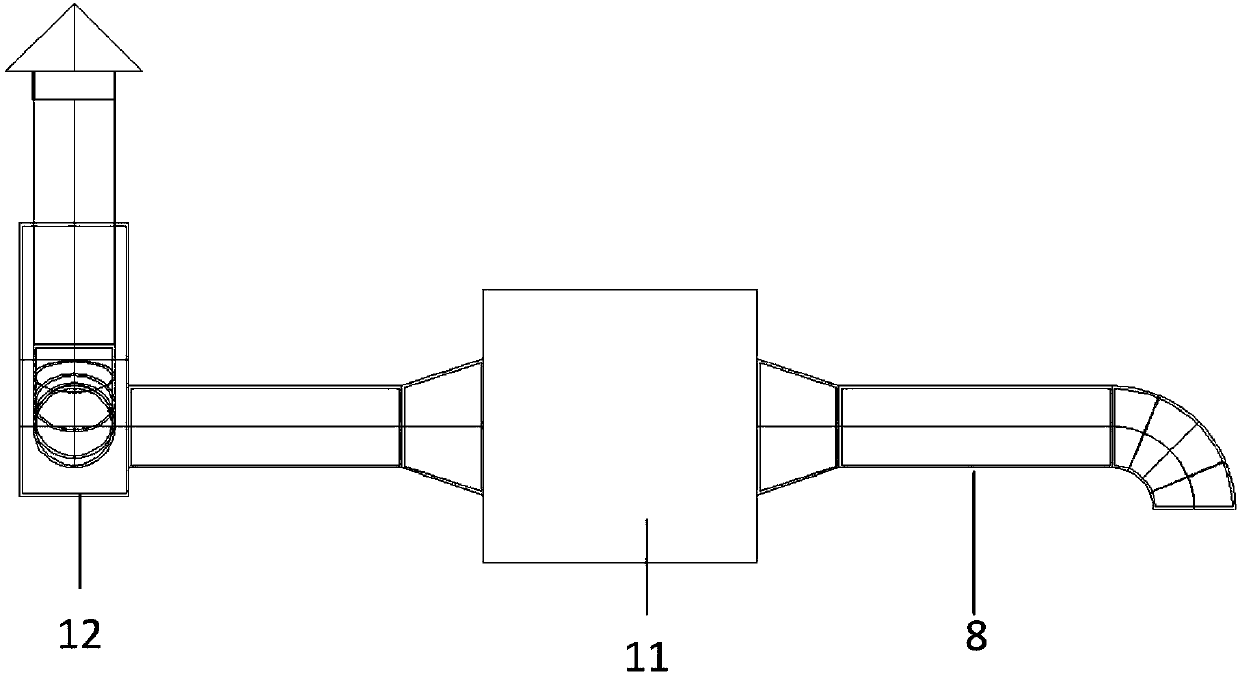

Ventilating device

InactiveCN102937318ALarge range of controlSimple structureLighting and heating apparatusVentilation systemsPulp and paper industryExhaust pipe

The invention discloses a ventilating device. The ventilating device comprises an air supply fan, an air supply pipe, an exhaust fan and an exhaust pipe. The ventilating device is characterized by further comprising an air-supply static pressure box and an exhaust static pressure box, wherein an air outlet of the air supply fan is connected with an air inlet of the air-supply static pressure box by the air supply pipe; and an air outlet of the exhaust static pressure box is connected with an air inlet of the exhaust fan by the exhaust pipe. The ventilating device disclosed by the invention has the advantages that the structure is simple, the cost is low, the industrial pollution is controlled by utilizing air jetting, the control range of pollutants is large, the capture efficiency is high, the purposes of effectively controlling industrial pollution and protecting the occupational health are achieved, and simultaneously the energy is furthest saved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

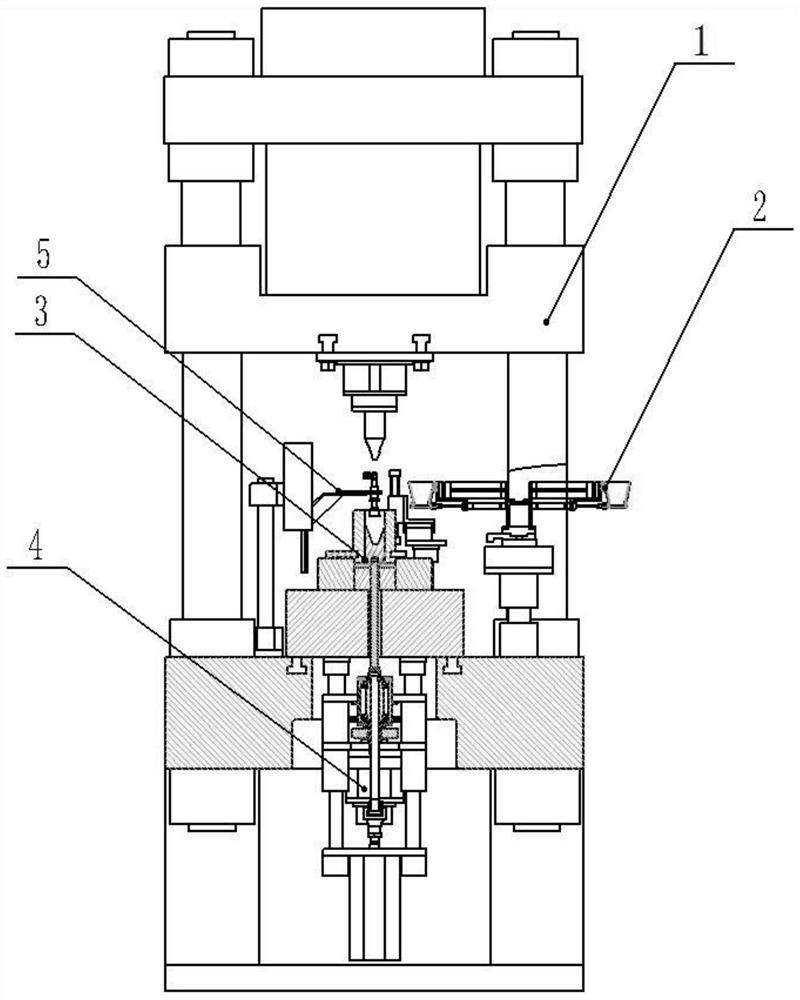

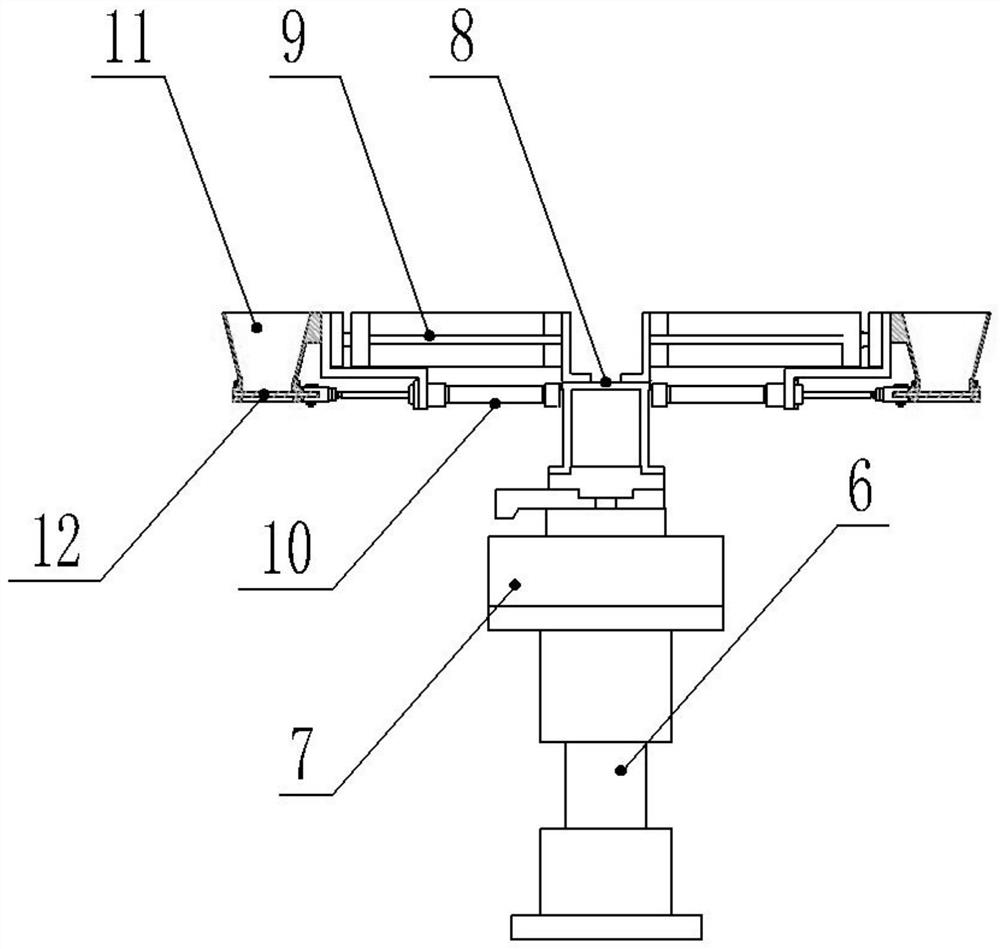

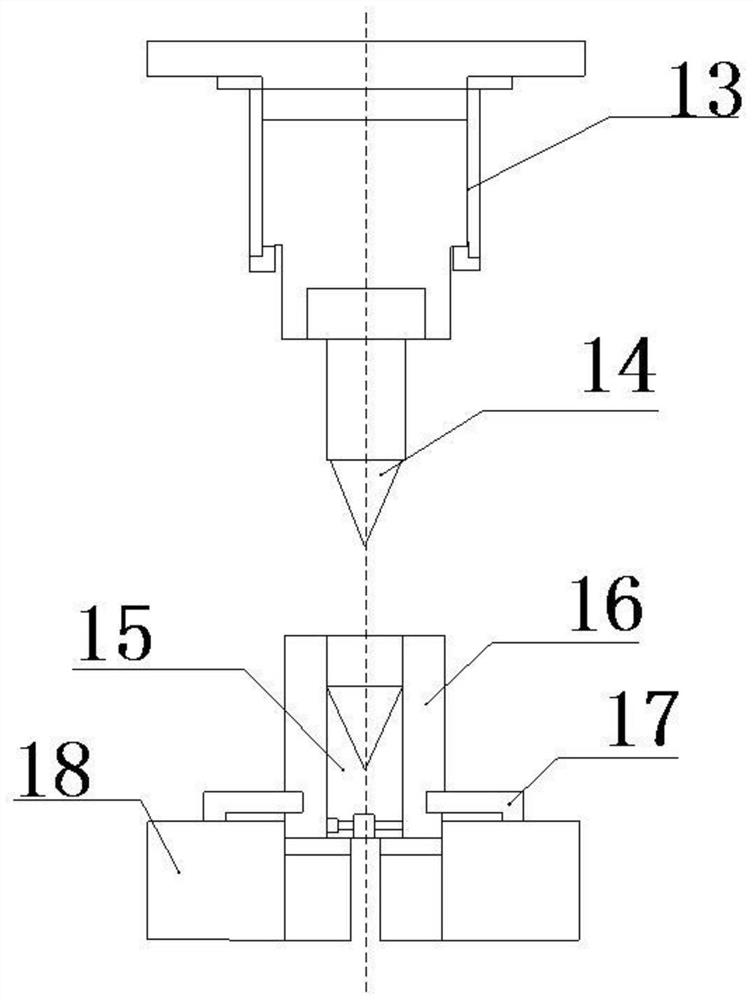

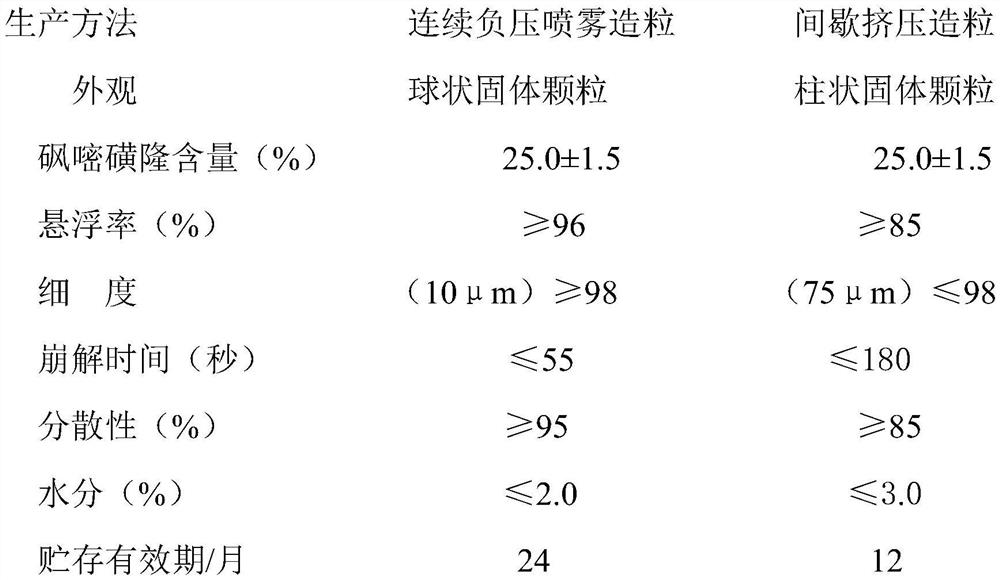

Automatic spinning forming device for powder liner

PendingCN112139490AEasy to replaceEasy to take outTurbinesOther manufacturing equipments/toolsSpinningMetal powder

The invention provides an automatic spinning forming device for a powder liner. The automatic spinning forming device comprises a four-column hydraulic machine, a powder feeding assembly, a die assembly, a powder spinning die retreating assembly and a liner taking assembly, wherein the die assembly is mounted in the right center of a workbench of the four-column hydraulic machine, the powder spinning die retreating assembly is mounted below the die assembly and is connected with the die assembly through a connecting rod, and the powder feeding assembly and the liner taking assembly are mountedon the two sides of the workbench correspondingly. According to the automatic spinning forming device for the powder liner, when powder liner spinning forming production is conducted, the powder feeding assembly feeds raw material metal powder into the die assembly, the powder spinning die retreating assembly drives the metal powder to rotate, punch forming is conducted after powder spinning, after pressing is completed, the powder spinning die retreating assembly retreats from a die, and the liner is taken out through the liner taking assembly; and in the whole production process, automaticand continuous production of the powder liner spinning forming procedure is achieved, the production efficiency is improved, the labor intensity of personnel is greatly reduced, the safety risk is reduced, noise pollution is reduced, and occupational health of the personnel is protected.

Owner:CHINA SOUTH IND GRP AUTOMATION RES INST

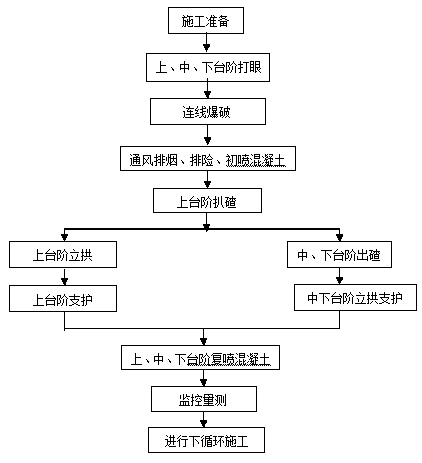

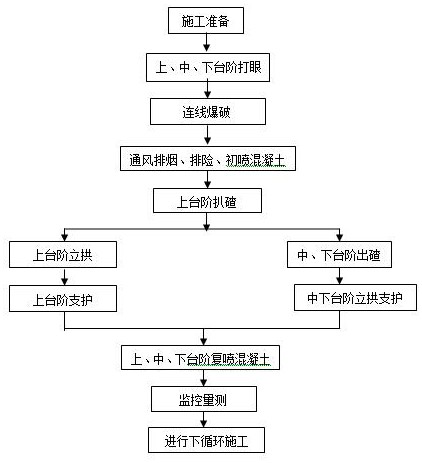

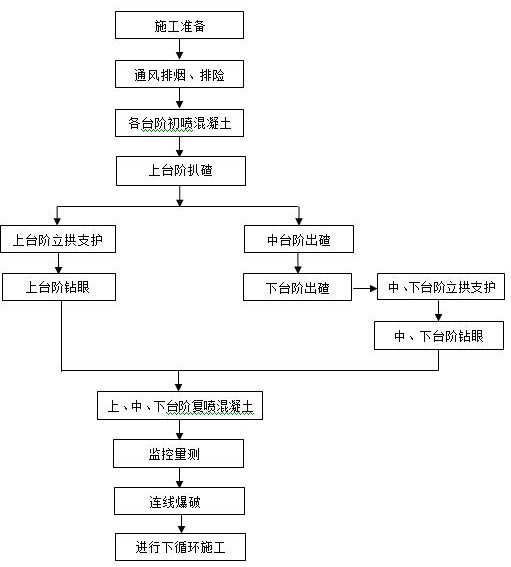

Tunnel excavation construction organization method based on three-bench method

ActiveCN110259459AEfficient constructionImprove excavation construction progressUnderground chambersTunnel liningWorkloadConstruction scheduling

The invention provides a tunnel excavation construction organization method based on a three-bench method. The tunnel excavation construction organization method is innovated, operation groups are arranged mixedly, the workload of each bench operation is adjusted, the construction time required by each working procedure is comprehensively considered, so that workers, operation task load and the operation time of each working procedure are matched, a construction organization mode combining a flow-line operation with a parallel operation is formed, the tunnel single excavation cycle operation time constructed by the three-bench method can be effectively shortened, and the excavation construction progress is improved.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

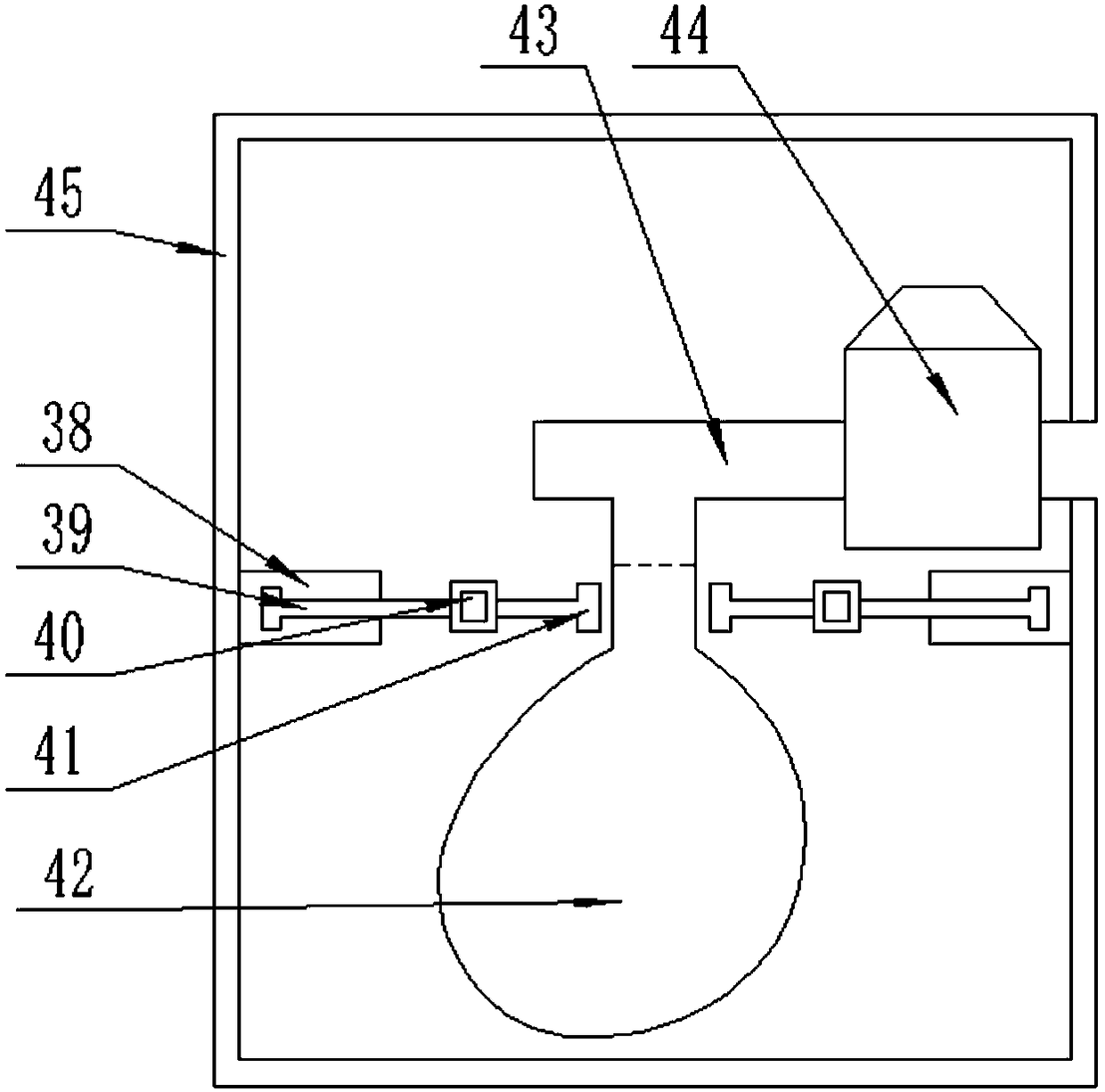

Concentrated feed waste gas treatment device

PendingCN107469619ASolve pollutionInhibited DiffusionGas treatmentDispersed particle separationSpray nozzleWaste collection

The invention relates to a concentrated feed waste gas treatment device. The device comprises a gas collecting pipe, an air inlet pipe, a purifying device, an air outlet pipe and an exhaust opening which are arranged in sequence, wherein a booster fan and a treatment chamber are arranged on the air outlet pipe, and the booster fan is positioned above the treatment chamber; the discharge opening of the treatment chamber is provided with a solid outlet and a gas outlet, a waste collection tank is connected with the lower side of the solid outlet, and the gas outlet is connected with a dust collector; the outlet of the dust collector is connected to the air outlet pipe under the treatment chamber; a catalyzing device is arranged in the purifying device, a liquid spray tank is formed in the side of the purifying device and comprises a first spray nozzle connected with the tail end of the air inlet pipe and a second spray nozzle connected to the front end of the air outlet pipe; pressure sensors are arranged on the first and second spray nozzles; sensitive signals of the pressure sensors are conducted to a controller of the liquid spray tank; and the controller is used for controlling start and close and openness of the first and second spray nozzles.

Owner:ANHUI TIANLONG FEED

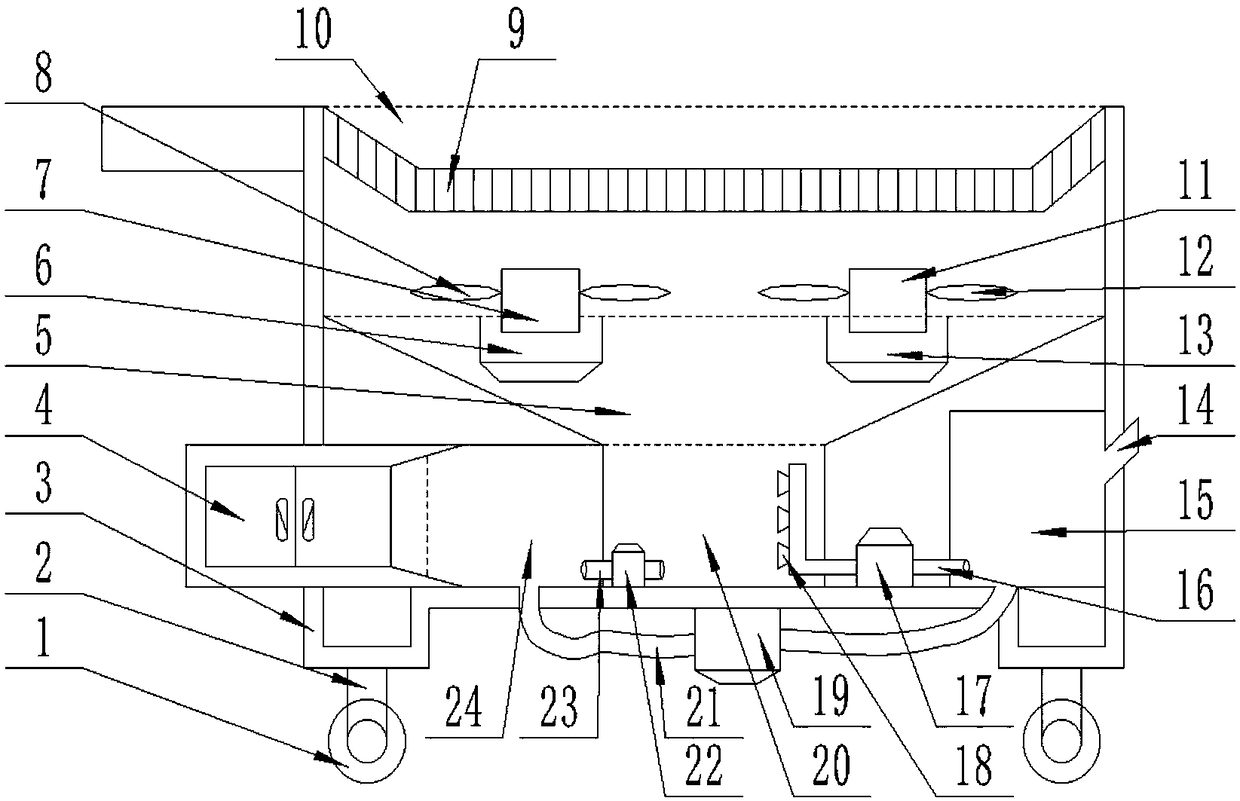

Dust collection vehicle for production workshop

InactiveCN108379979AEasy to cleanProtect hygieneCombination devicesWrapper twisting/gatheringHydraulic cylinderHeat conducting

The invention discloses a dust collection vehicle for a production workshop. The dust collection vehicle comprises universal wheels, universal wheel supporting rods, a machine frame, a collecting device, a ventilating chamber, a first motor, a first fan connecting rod, a first fan, a first filtering net and a dust inlet. The universal wheels are arranged at the bottom of the dust collection vehicle to realize a high moving capability, the fan is driven by the motor to suck air, the air enters a spraying chamber, dusts fly over the sky, water in a water tank is pumped through the water pump, issprayed, enters a solid-liquid separation device, and is precipitated by the bottom filtering net, the superfluous liquid returns to the water tank, a hydraulic cylinder pushes a push plate in orderto push solids to a left solid outlet, a hairbrush can clean the inner wall, the solids enter the collecting device, are pumped into a thickened plastic bag through an air pump, and are inwardly pushed through two side cylinders, and an electric heater drives a heat conducting rod to generate heat in order to thaw and bind the mouth of the thickened waste bag in order to form sealing, so the dustscan be conveniently cleaned.

Owner:覃树强

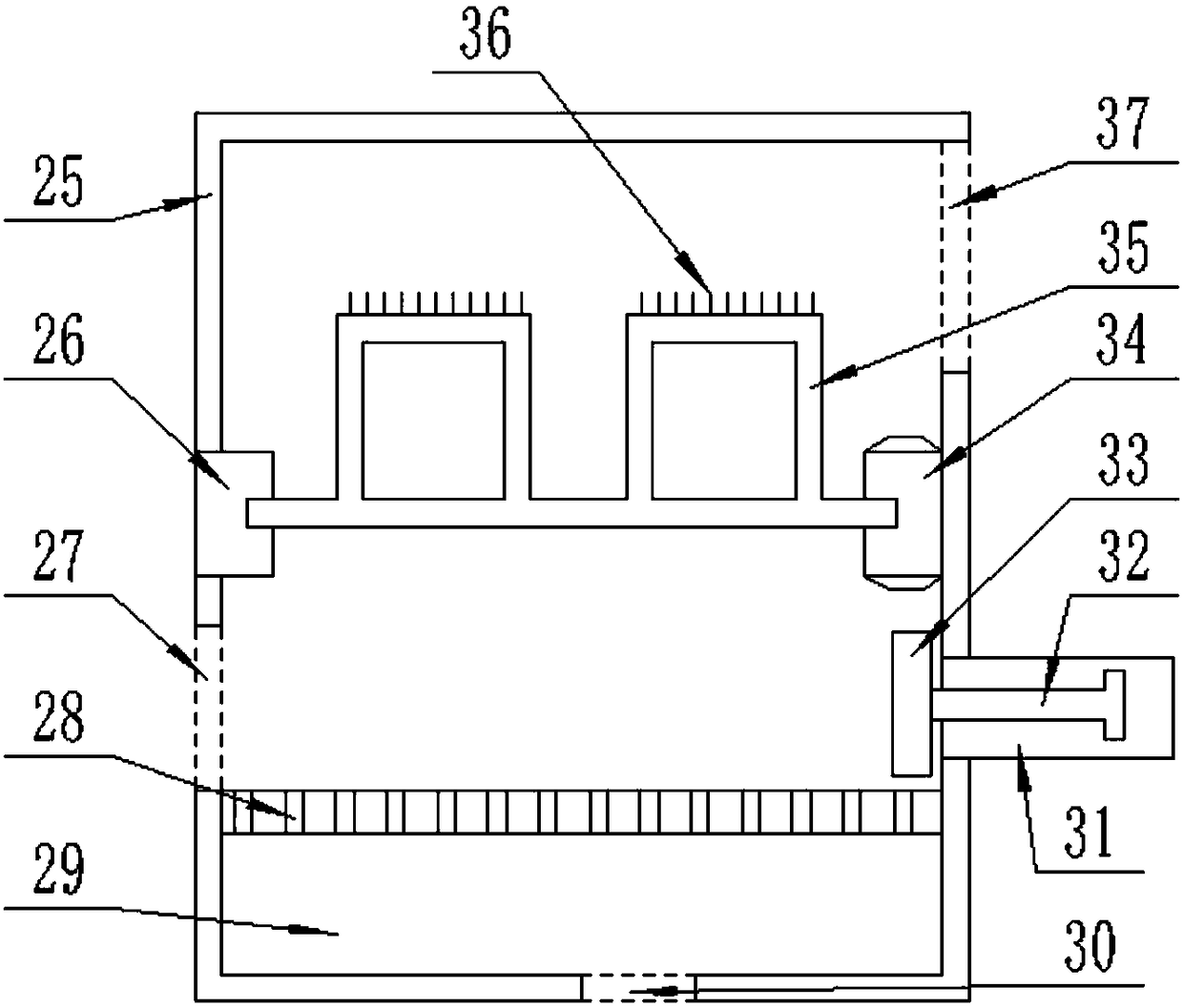

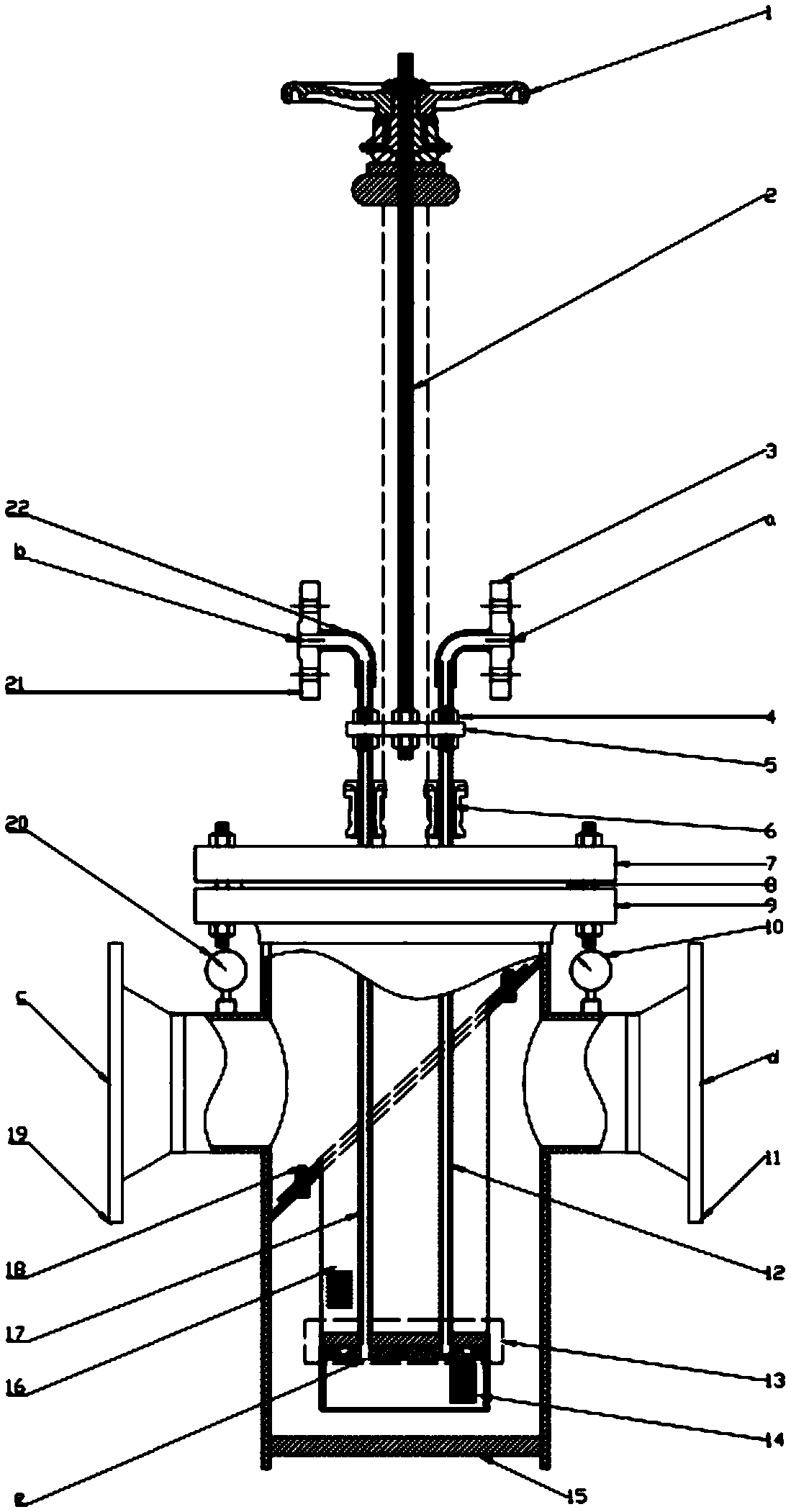

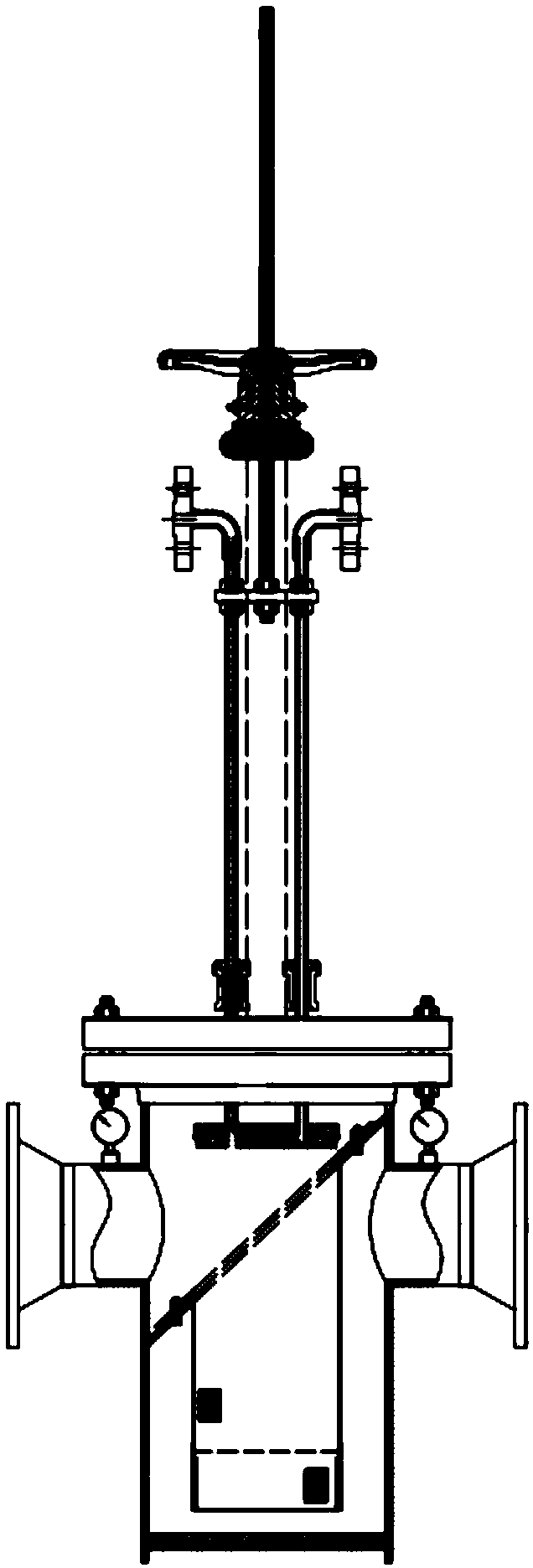

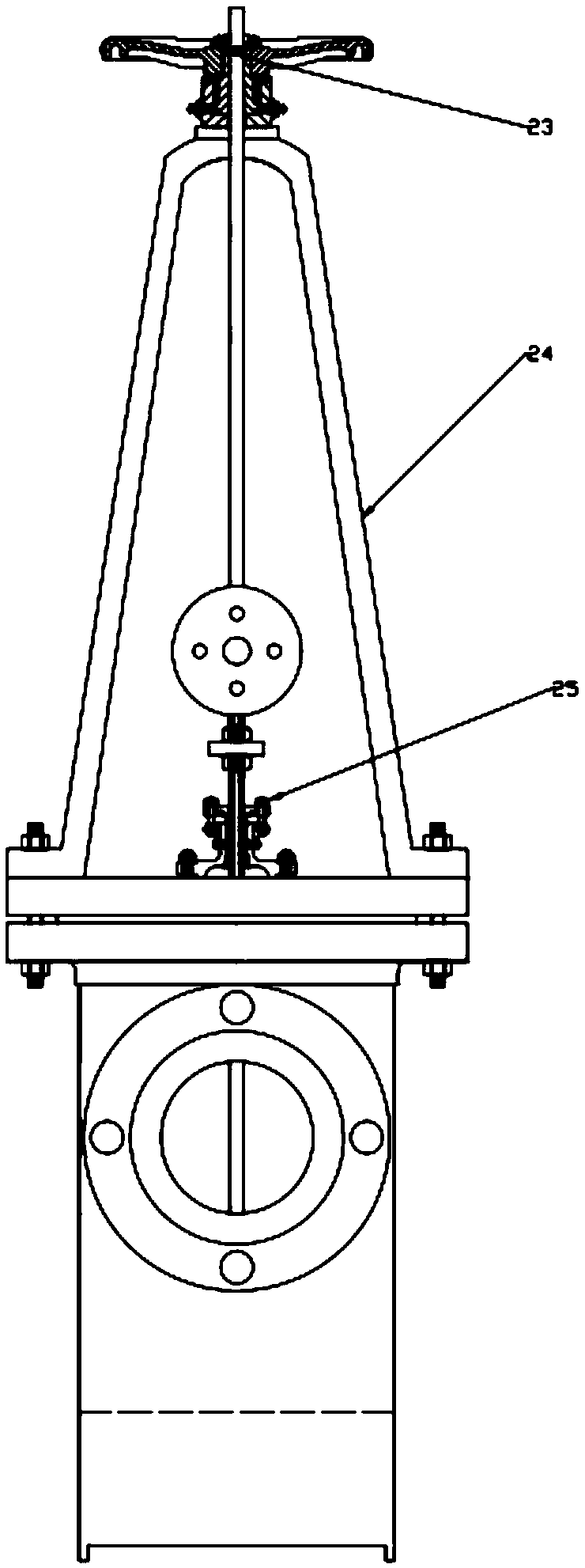

Online cleaning basket filter for high-concentration formaldehyde pipeline in production technology of trioxymethylene

ActiveCN109173408AEffectively predict working statusExtended service lifeMembrane filtersFiltration separationHigh concentrationWorkload

The invention discloses an online cleaning basket filter for a high-concentration formaldehyde pipeline in the production technology of trioxymethylene. The basket filter comprises a basket filter body, a scraping jet cleaner, a hollow cleaning support rod I, a hollow cleaning support rod II, a hand wheel, a transmission rod and a transmission force distribution plate; a sealing cover is arrangedat the upper open end of the basket filter body, the hollow cleaning support rods I and the hollow cleaning support rod II respectively vertically go through the sealing cover and are connected with the scraping jet cleaner, the top ends of the hollow cleaning support rod I and the hollow cleaning support rod II are located at the upper part of the sealing cover and are respectively connected withthe lower end of the transmission rod through the transmission force distribution plate, the upper end of the transmission rod is connected with the hand wheel, and the hand wheel is located at a power support at the upper part of the sealing cover. The basket filter can realize online cleaning at any time without affecting the running of a system, and also can realize closed cleaning in order toeffectively control the pollution of toxic and harmful media to the environment and the occupational health of operators. The basket filter prolongs the overhaul period to one year or above in orderto greatly reduce the workload of the operators.

Owner:YANKUANG GRP CO LTD

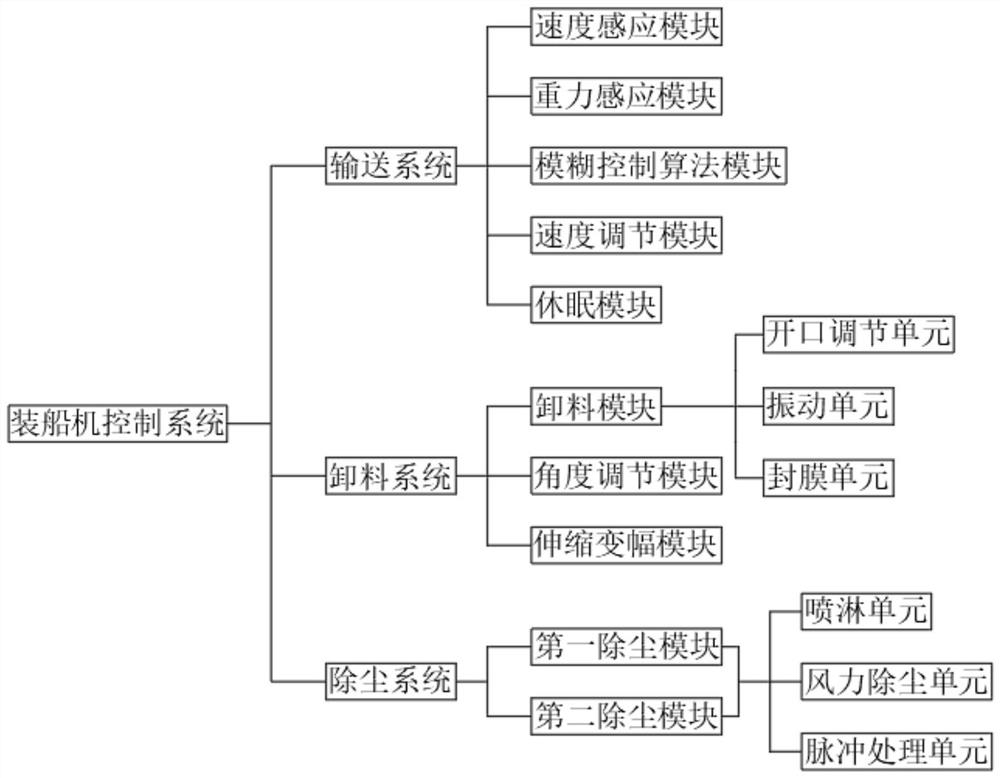

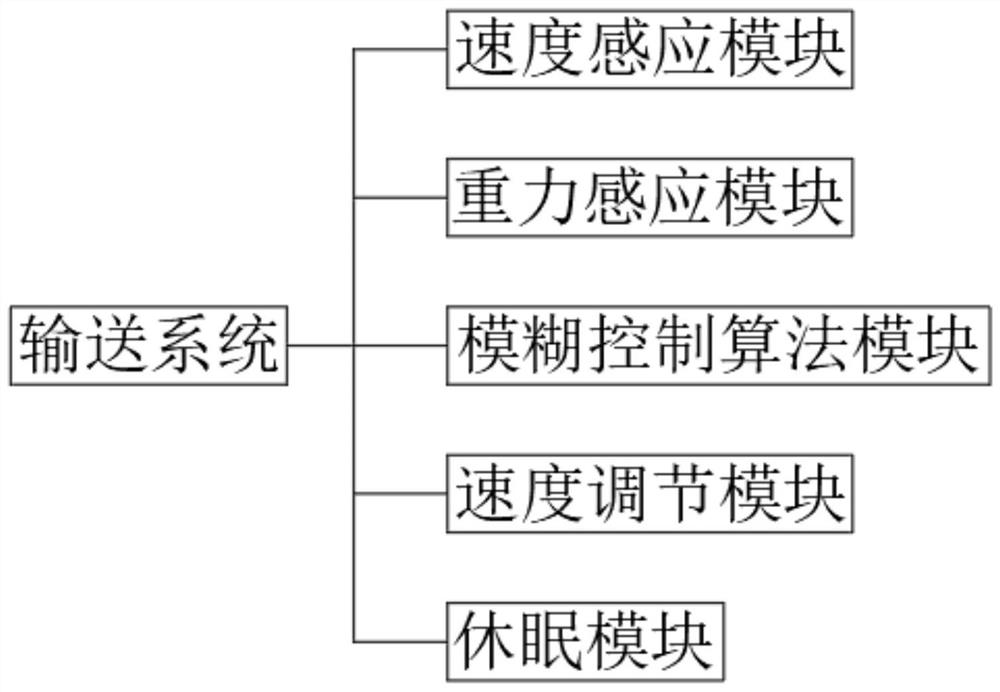

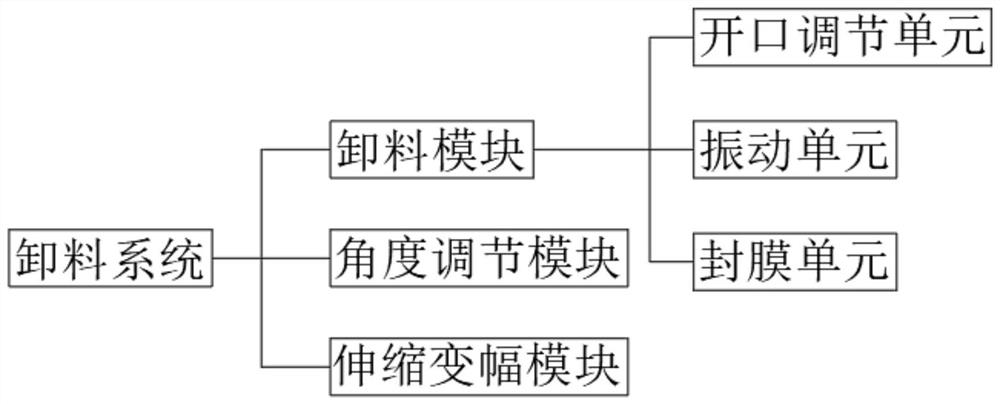

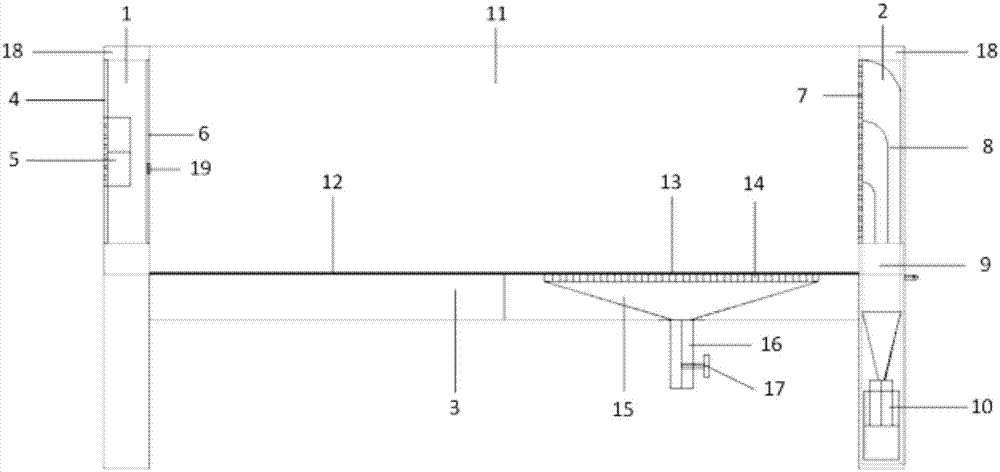

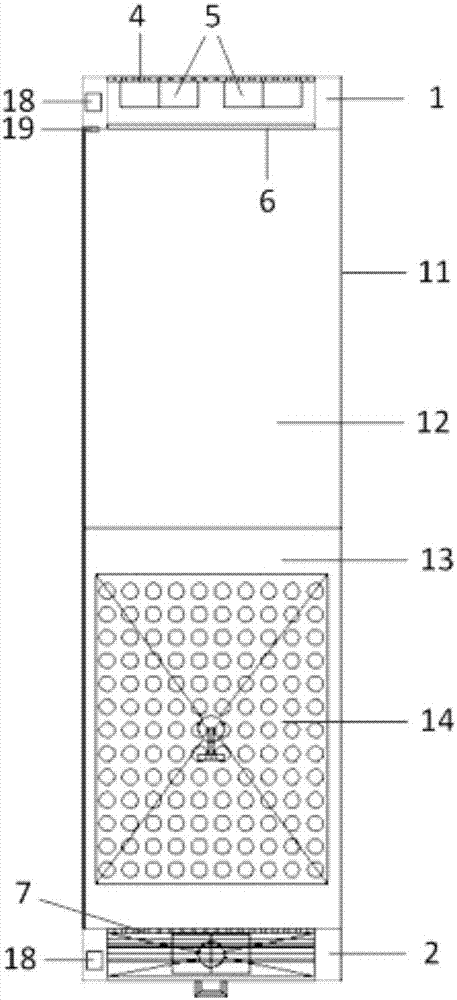

Automatic environment-friendly telescopic variable-amplitude ship loader control system

PendingCN114516552AProtect occupational healthReduce secondary loading and unloadingControl devices for conveyorsLoading/unloadingControl systemDust control

The invention relates to the technical field of ship loader control, and discloses an automatic environment-friendly telescopic variable-amplitude ship loader control system which comprises a conveying system, an unloading system and a dust removal system. The conveying system adopts belt type conveying equipment, and a conveying speed and load fuzzy controller model is constructed by adopting a fuzzy algorithm by modeling factors influencing the system energy consumption of the belt type conveying equipment. Through cooperative use of the conveying system and the unloading system, after a conveying vehicle reaches an unloading position, unloading is started to be conducted into the unloading hopper, the unloading hopper is conveyed to a designated cabin position through the feeding mechanism, and automation of the ship loading process is achieved; in the whole unloading process and the ship loading process, field operation of operators is not needed, and the occupational health of the operators is greatly protected; meanwhile, due to automatic operation in the whole process, a large amount of labor cost is saved for a wharf operation mechanism; secondary loading and unloading on site are reduced, production efficiency is improved, loading and unloading cost is reduced, and the purposes of environmental protection, safety, energy conservation and easy operation are mainly achieved.

Owner:江苏祥瑞港机设备有限公司

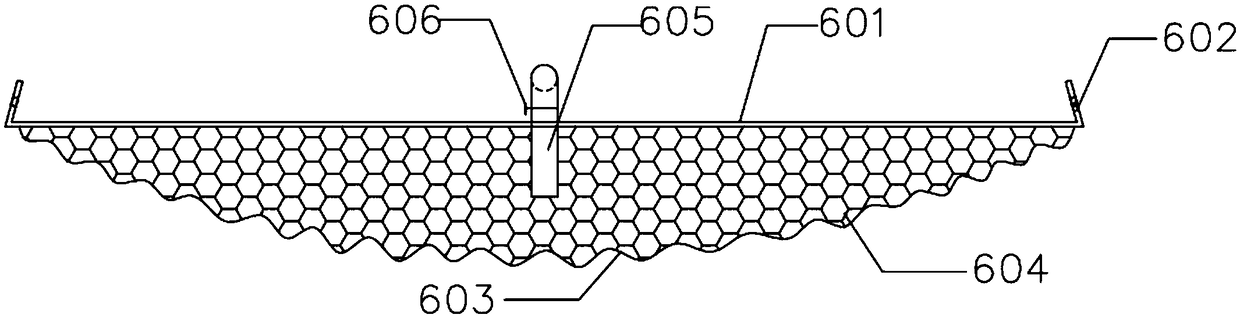

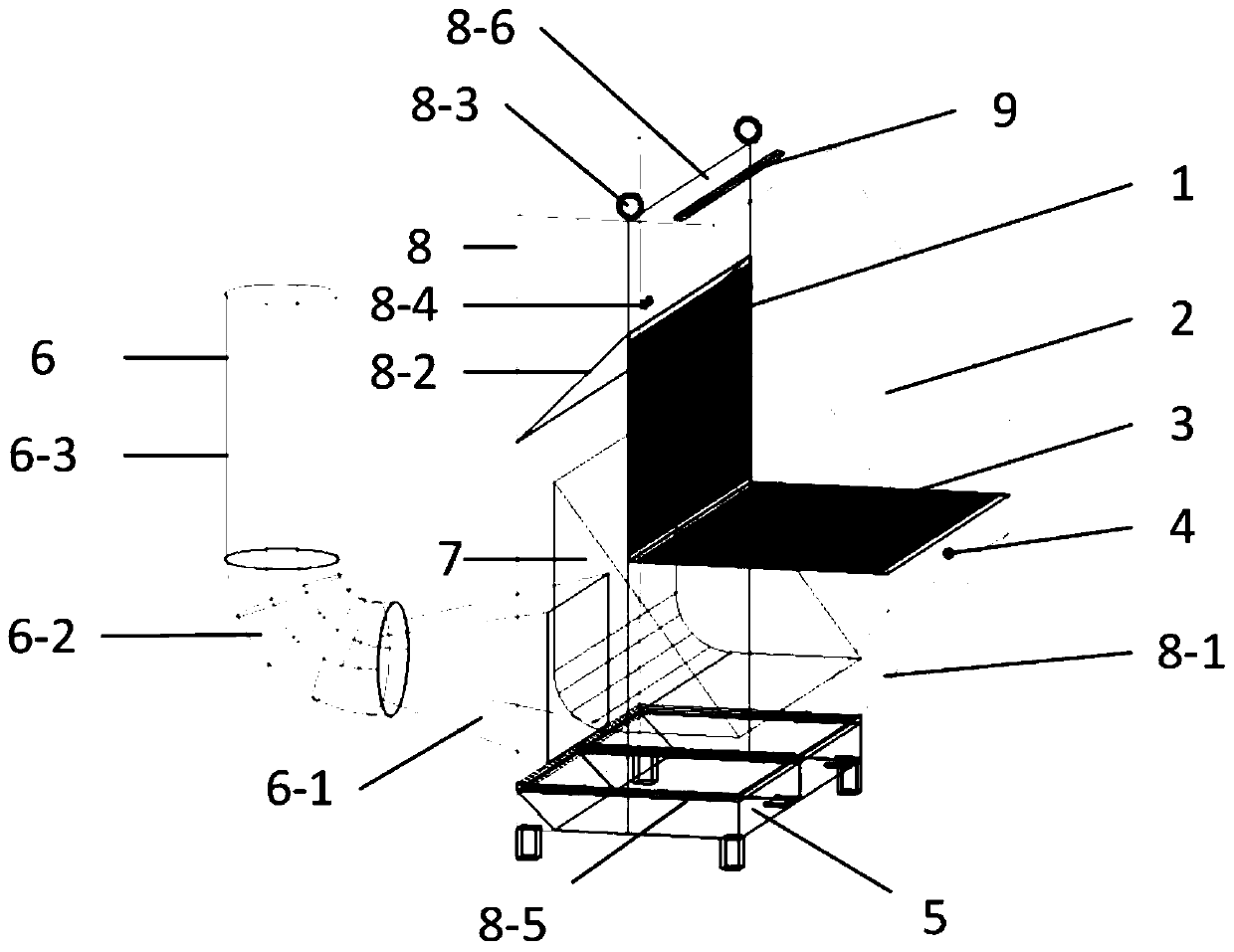

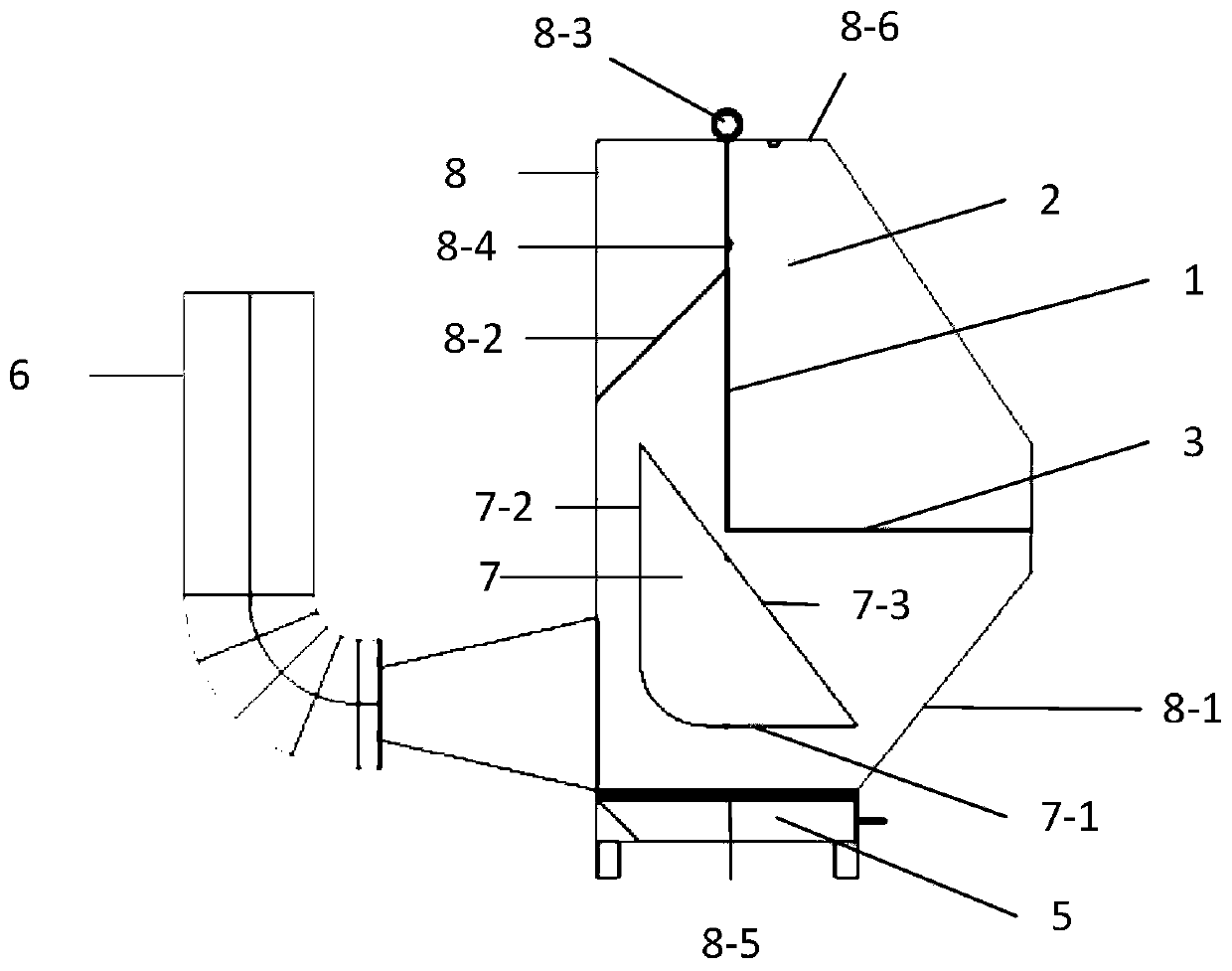

Open blowing/suction type ventilation poison-proof plate washing worktable

PendingCN107321751APrevent escapeAvoid pollutionDispersed particle separationDirt cleaningAutomatic controlAgricultural engineering

The invention discloses an open blowing / suction type ventilation poison-proof plate washing worktable. The worktable mainly comprises a uniform air supply device, a uniform exhaust device and a plate washing working platform. The worktable can effectively solve the technical difficulties of large-area poison dispersion and long-distance control in a plate washing room, prominently reduces the poison concentration in the plate washing room, protects occupational health of workers, realizes automatic control of the air supply device and the exhaust device, and achieves the purpose of energy conservation. The open blowing / suction type ventilation poison-proof plate washing worktable can be widely applied to plate washing operation places in the electronic industry, and is broad in application prospect.

Owner:CHINA ACAD OF SAFETY SCI & TECH

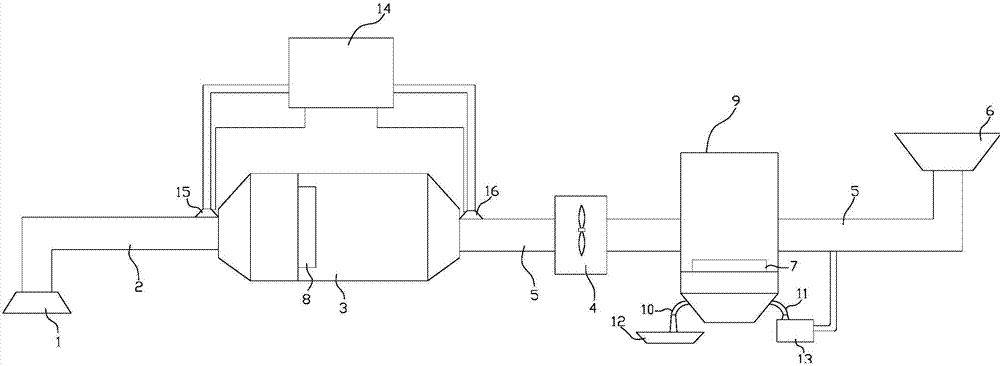

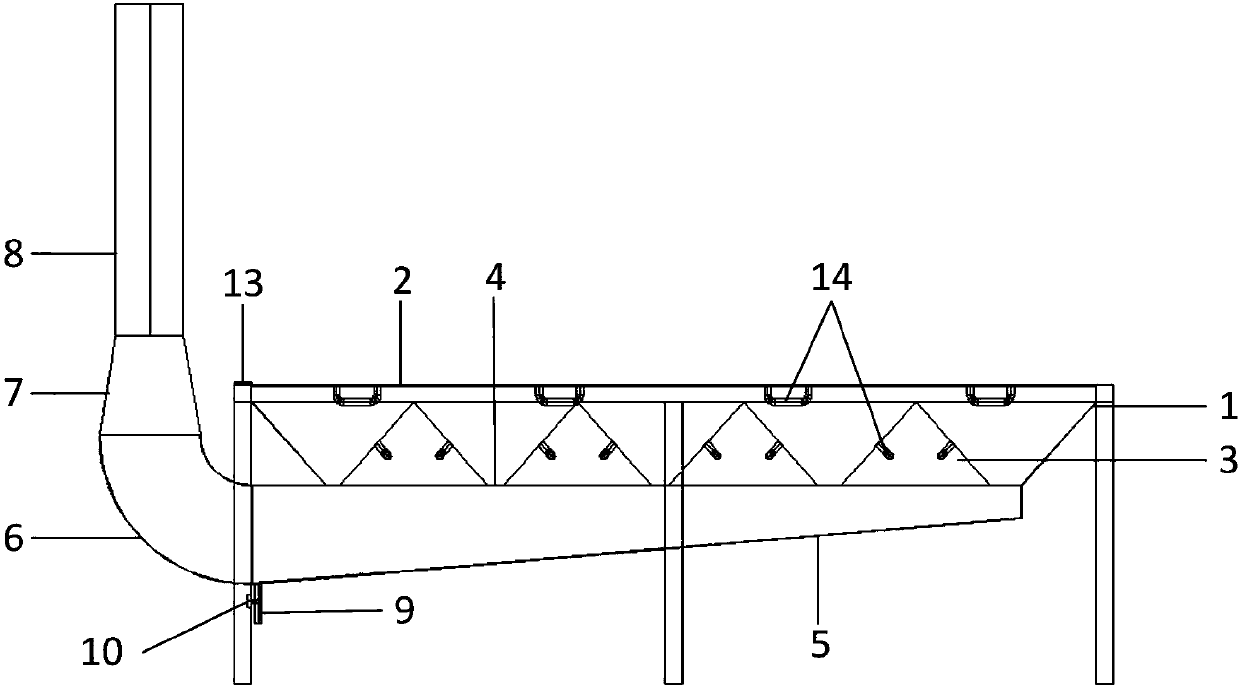

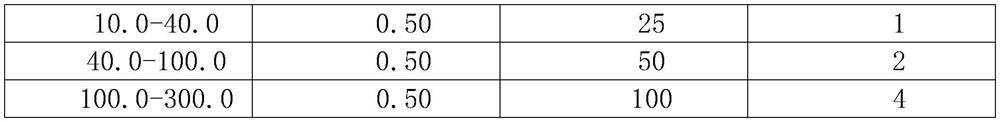

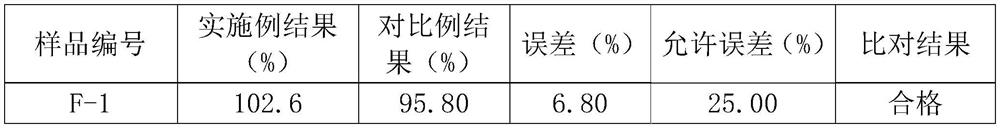

Uniform and lower exhaust type large-area workbench

PendingCN107702255ASolve the technical problem of uniform lower exhaust airImprove controlMechanical apparatusSpace heating and ventilation safety systemsAutomatic controlReducer

A uniform and lower exhaust type large-area workbench mainly comprises a lower-exhaust workbench body, a purifying device, a draught fan, a frequency converter and an air pipe. The lower-exhaust workbench body is composed of a workbench shell, a porous plate work tabletop, a triangular rectification structure, a rectification narrow seam, a rectification base plate, an elbow, a reducer pipe, the air pipe, a liquid discharging pipeline, a liquid discharging valve, an automatic control device and a flip hidden handle. By the adoption of the uniform and lower exhaust type large-area workbench, the evenness of lower exhaust can be effectively improved when the large-area workbench conducts one-side exhaust, the technological problem that when the large-area workbench is used for operation, poisonous substances cannot be effectively controlled due to one-side exhaust is solved, the concentration of the poisonous substances is effectively controlled when the large-area operation workbench isused for operation; and in this way, the occupational health of workers is protected, automatic control over an exhaust device of the large-area workbench is achieved, and the energy-saving purpose is achieved.

Owner:CHINA ACAD OF SAFETY SCI & TECH

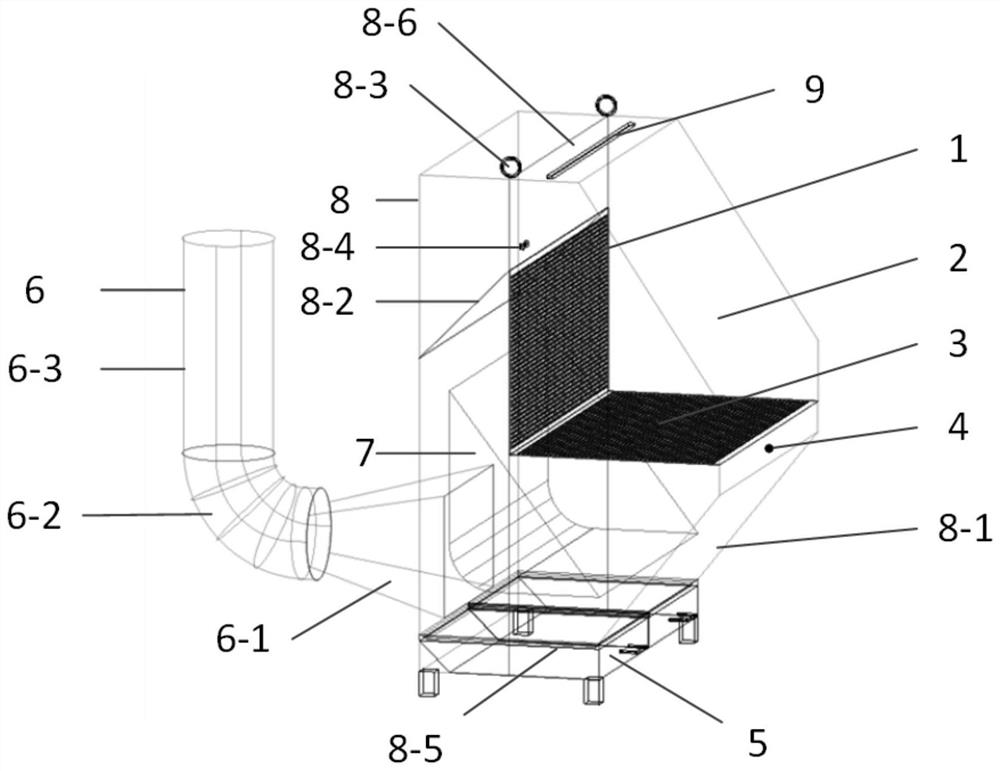

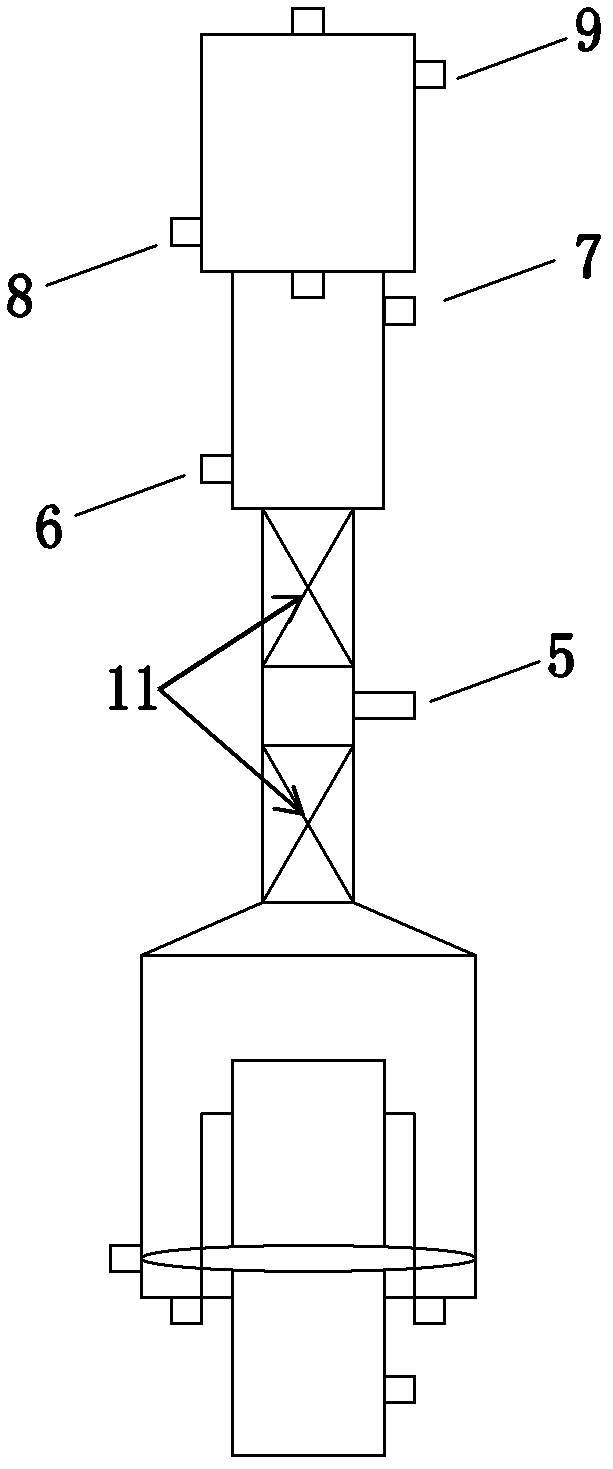

Efficient dust collecting and polishing workbench

ActiveCN110977778AAchieve closureProtect occupational healthGrinding carriagesGrinding bedsIlluminanceEngineering

An efficient dust collecting and polishing workbench comprises a back plate, baffles, a workbench top, a human body inductor, a dust collecting drawer, an air pipe, a built-in rectifying structure, anequipment shell and an illuminating lamp; the back plate is fixed on the equipment shell, the workbench top is embedded in the equipment shell, and the baffles are arranged on two sides of the workbench top; the dust collecting drawer is embedded in the equipment shell, and is disassembled and assembled through a handle; the built-in rectifying structure is a hollow structure formed by splicing three enclosing plates, and is embedded in the equipment shell; the equipment shell comprises a front rectifying plate and a top rectifying plate, and the equipment shell and the built-in rectifying structure jointly act to determine the air quantity distribution and the air speed distribution of the workbench back plate and the workbench top; and two lifting rings are arranged at the top of the equipment shell, so that installation and transportation of equipment are facilitated; and the illuminating lamp is arranged below a top plate of the equipment shell and used for ensuring illumination required by polishing. The workbench is simple in structure, high in dust catching rate, automatic in control and easy to clean.

Owner:CHINA ACAD OF SAFETY SCI & TECH

A high-efficiency dust collection and grinding workbench

ActiveCN110977778BAchieve closureProtect occupational healthGrinding carriagesGrinding bedsAutomatic controlEngineering

Owner:CHINA ACAD OF SAFETY SCI & TECH

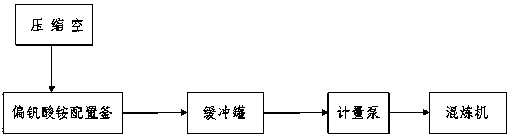

Automatic conveying method for ammonium metavanadate solution

InactiveCN108870079AReduce exposureAvoid occupational hazardsPipeline systemsEcological environmentBuffer tank

The invention discloses an automatic conveying method for ammonium metavanadate solution. A compressed air source is introduced by an exhaust hole in an ammonium metavanadate solution configuration kettle, a buffer tank is additionally arranged, a process pipeline is installed from the bottom of the configuration kettle to the buffer tank, a pipeline is installed from the buffer tank to an inlet of a metering pump, and the ammonium metavanadate solution is sent to a mixing machine through the metering pump. The method has the advantages that sealing and conveying of the ammonium metavanadate solution are realized, personnel contact is reduced, and occupational health and ecological environment of workers are protected; and the labor intensity of workers is reduced; and the adding amount ismore accurate during the material mixing process.

Owner:新疆中泰国信节能环保有限公司

A Tunnel Excavation Construction Organization Method Based on the Three-step Method

ActiveCN110259459BImprove excavation construction progressEffective connectionUnderground chambersTunnel liningConstruction engineeringConstruction scheduling

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

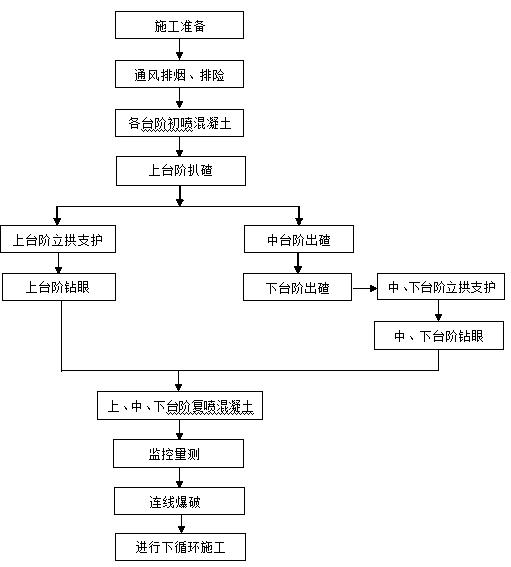

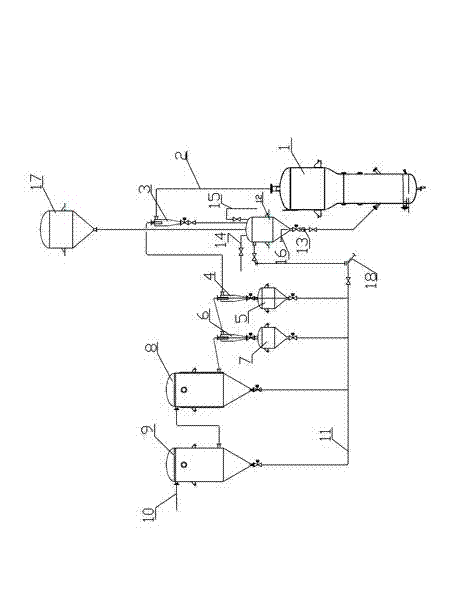

Method for recycling waste silicon powder in production process of trichlorosilane

InactiveCN101966993BReduce consumptionReduce manufacturing costCombination devicesSiliconCycloneSlag

The invention discloses an equipment for producing trichlorosilane by comprehensively utilizing waste silicon powder. The equipment comprises a trichlorosilane synthetic furnace mixed gas outlet pipe connected with a high-efficiency cyclone separator; wherein a material discharge port of the high-efficiency cyclone separator is connected with a silicon powder recovery tank; a gas outlet of the high-efficiency cyclone separator is connected with a primary cyclone separator; a primary slag storage tank is arranged below the primary cyclone separator; the gas outlet of the primary cyclone separator is connected with a secondary cyclone separator; a secondary slag storage tank is arranged below the secondary cyclone separator; the gas outlet of the secondary cyclone separator is connected with a primary bag-type dust remover and a secondary bag-type dust remover in turn; both the material discharge ports of the primary bag-type dust remover and the secondary bag-type dust remover are connected with the silicon powder recovery tank through slag blowing pipes; and the material discharge port of the silicon powder recovery tank is connected with a recovery port of the trichlorosilane synthetic furnace. The equipment has the characteristics of obvious energy conservation effect, high environmental protection benefit, high safety factor, unique process, simplicity and long service life, and is easy to operate and the like.

Owner:河南尚宇新能源股份有限公司

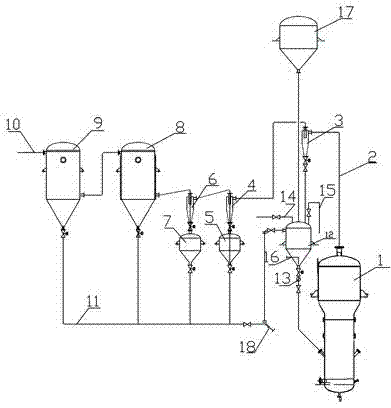

Water dispersible granule of corn herbicide rimsulfuron and clean production method thereof

PendingCN113383772ANo Spill ContaminationEasy to cleanBiocideAnimal repellantsSpray GranulationWater dispersible

The present invention discloses a water dispersible granule of a corn herbicide rimsulfuron and a clean production method thereof. The water dispersible granule comprises a rimsulfuron original medicine, an auxiliary agent, a carrier filler and water, wherein the content of rimsulfuron is 20-25%, and all the raw materials are commercially available commodities. The clean production method comprises three steps, namely wet-process negative-pressure mixing, negative-pressure fineness crushing and negative-pressure spray granulation. The continuous clean production method of the water dispersible granule adopts closed production in the whole process of spray drying after whole-process negative-pressure and wet-process crushing, so compared with an intermittent water-dispersible pesticide granule production line, production links are reduced, a pesticide is finer, the use efficiency of the pesticide is higher, no pesticide dust overflows, loss is greatly reduced, the production cost can be reduced, environmental pollution caused by pesticide dust and waste gas in a production process can be effectively reduced, the environmental cleanliness of a production environment is improved, the occupational health of workers can be well protected, and the utilization rate of powder can be improved.

Owner:JIANGSU RUIDONG PESTICIDE

A kind of titanium dioxide surface treatment method and modified titanium dioxide

ActiveCN110606507BImprove liquidityImprove temperature resistanceTitanium dioxidePigment treatment with non-polymer organic compoundsPhosphoric Acid EstersPhosphate

Owner:HENAN BILLIONS NEW MATERIAL CO LTD

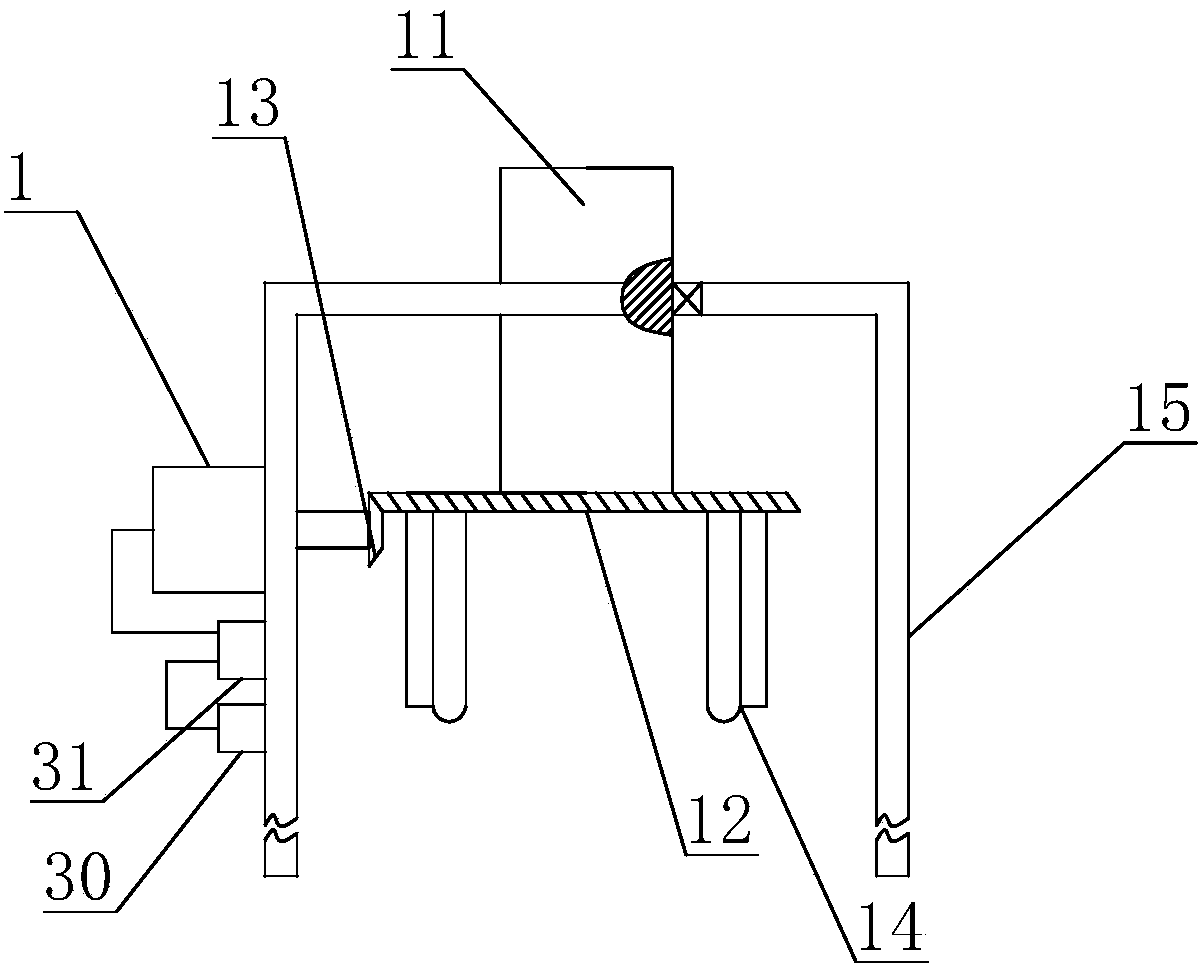

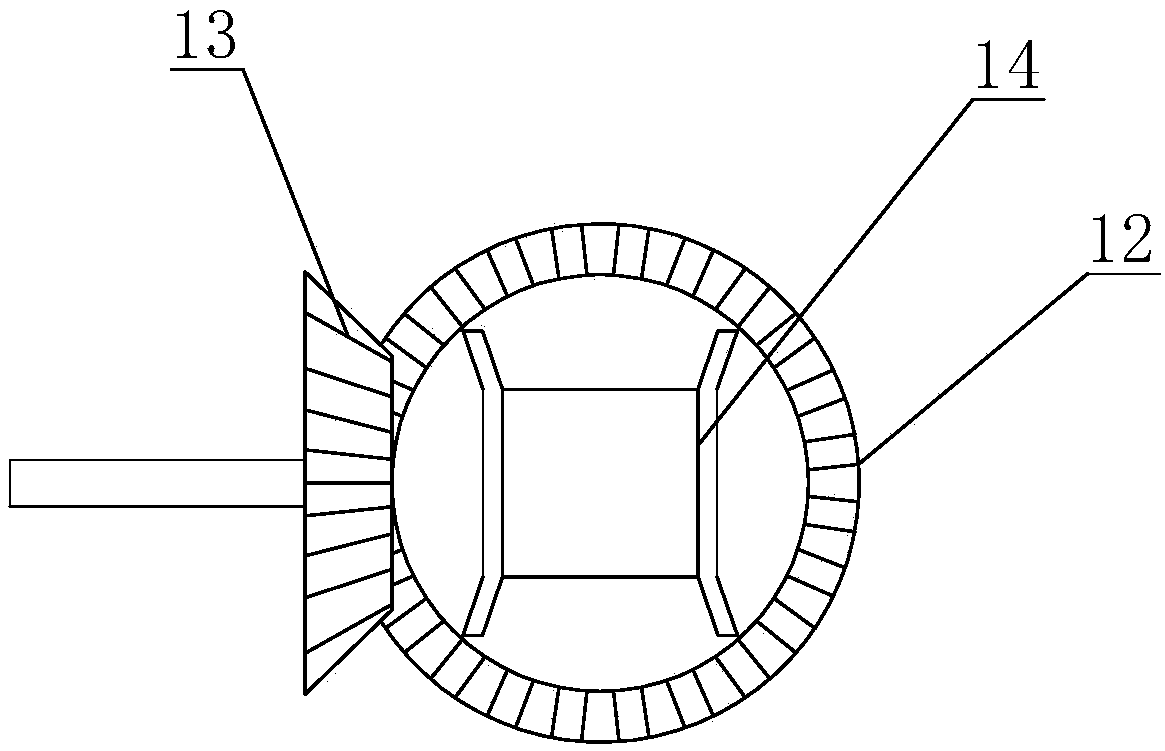

Movable cement dedusting and loading device

PendingCN108466850AReduce dust concentrationProtect occupational healthConveyorsLoading/unloadingEngineeringBevel gear

The invention discloses a movable cement dedusting and loading device and relates to the technical field of environmental protection. The movable cement dedusting and loading device comprises a cementtransportation device, a moving device and a dedusting device, wherein the cement transportation device comprises a base, bearing brackets are arranged on the upper part of the base, driving rollersare arranged between the bearing brackets, a conveyor belt is arranged between the driving rollers, a swing device is arranged on each bearing bracket, the swing device comprises a supporting rack which is separately connected to the two bearing brackets, a first bevel gear is arranged on the lower part of a rotary shaft, a second bevel gear is engaged to the first bevel gear, a swing channel is formed in the lower part of the first bevel gear, the swing channel is located on the upper part of the conveyor belt, a slideway is aligned to the outlet of the conveyor belt, a roller is in rolling connection to a movable bracket, and the output end of a first motor is connected to the roller. The movable cement dedusting and loading device has the beneficial effects that bagged cement can fall into a carrier vehicle automatically, and the dust concentration in a field environment can be reduced.

Owner:王柯桢

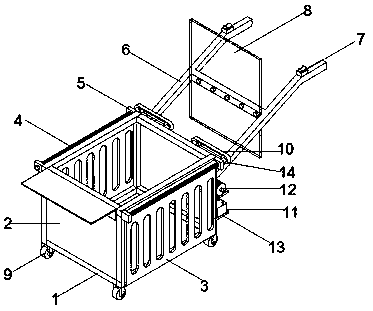

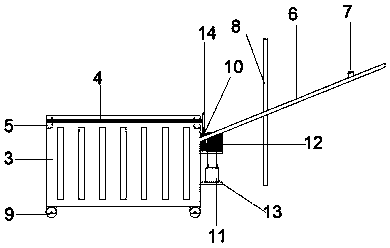

Small coke oven coke quenching vehicle

InactiveCN110746988AProtect job securityProtect occupational healthCoke quenchingHand carts with multiple axesHeat flowElectric machinery

The invention relates to a small coke oven coke quenching vehicle. The vehicle comprises a vehicle hopper frame, vehicle hopper protection plates, movable grille doors, grille door shafts, door shaftfixing devices, handlebars, control switches, a transparent protective heat insulation plate, wheels, transmission chains, storage batteries and transmission motors. The optimization of the small cokeoven coke quenching vehicle is benefited, traditional unprotected multi-person cooperative operation arrangement is changed to the arrangement of the small coke oven coke quenching vehicle operated by a single person. The front protective baffle plate is arranged at the front side of manual operation of the vehicle, and is transparent to make the coke quenching condition clearly observed, and theimpact of heat flow discharged from the coke oven is effectively blocked to protect the working safety and occupational health of staff; the vehicle can be continuously operated by the single person,and is simple to operate, so the working efficiency is increased; and the whole device is made of a stainless steel material, so the vehicle has low manufacturing cost, has certain economic benefits,and is suitable for being promoted and used.

Owner:TIANCHEN COAL MINE OF ZAOZHUANG MINING GRP

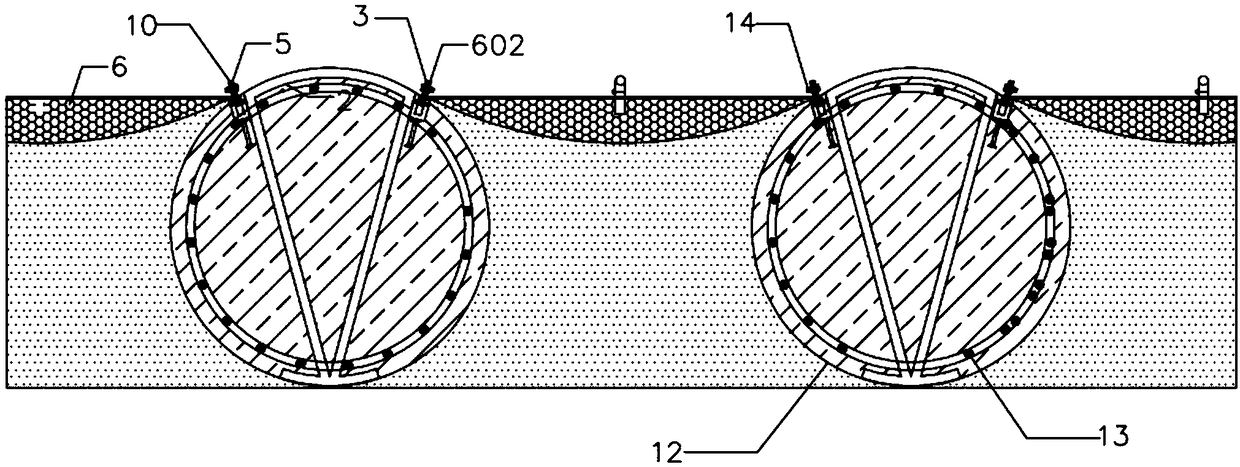

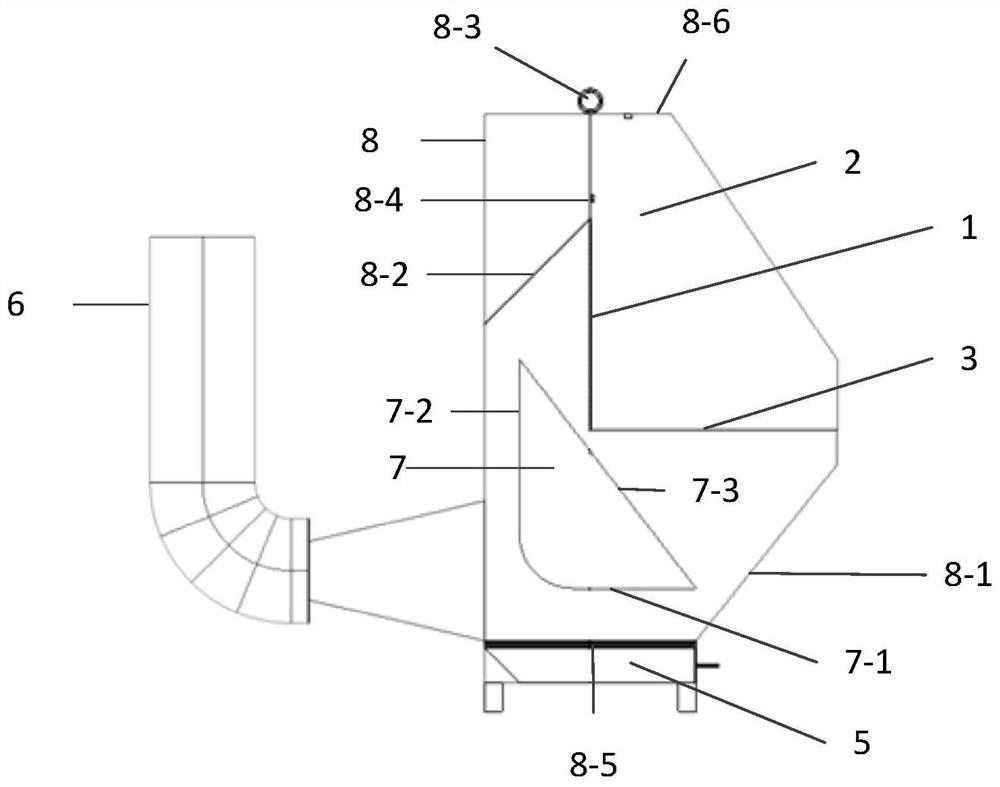

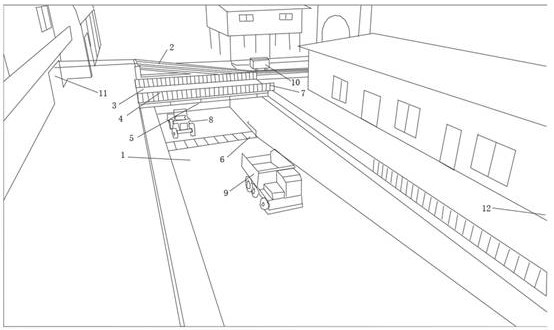

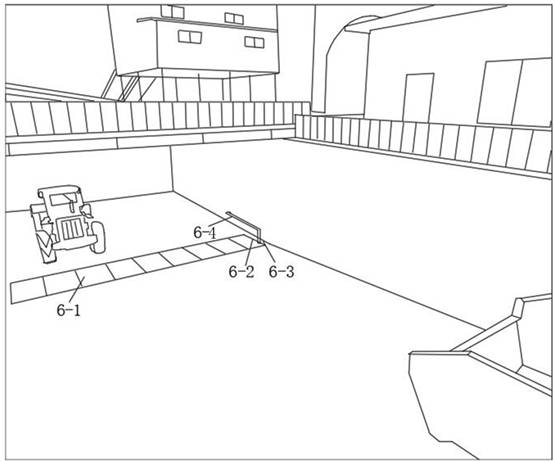

Sinking type slag discharging system for inclined shaft with rails

ActiveCN110294338AProtect occupational healthPromote environmental protectionSewerage structuresUsing liquid separation agentSlagAcousto-optics

The invention discloses a sinking type slag discharging system for an inclined shaft with rails. The system comprises a slag pool (1), a slag discharging platform (2), a pedestrian crossing trestle (3), an automatic spraying system (4), an acousto-optic alarm (5), a sewage collecting and discharging system (6) and protective railings (7), wherein the slag discharging platform (2) and the pedestrian crossing trestle (3) cross the slag pool (1); the protective railings (7) are arranged along the periphery of the slag pool (1); the automatic spraying system (4) is fixed on the protective railings(7); the acousto-optic alarm (5) is arranged at the bottom of the slag discharging platform (2); and the sewage collecting and discharging system (6) is arranged at the slope rising position of the slag pool (1). The system effectively solves the problems of environmental protection, energy conservation, emission reduction, and occupational health protection of sewage treatment and air dust reduction of a slag field at a hole of the inclined shaft with rails, as well as the problems of passing safety of workers entering and exiting the hole, safe operation of personnel and vehicles in a slagloading operation area at the bottom of the slag pool.

Owner:CHINA RAILWAY NO 5 ENG GRP

Multi-tunnel construction method based on weak interlayer

ActiveCN109737840BControl disturbanceConstruction safetyBlastingTunnelsGround subsidenceTEX-explosive

Disclosed is a multi-tunnel construction method based on weak interlayers, the method comprising the following steps: measuring the position of weak interlayers, uniformly distributing conduits in the weak interlayers, grouting the weak interlayers via the conduits to form a grouting area, A number of tunnels to be constructed are evenly distributed on both sides of the weak interlayer, and the geotechnical parameters of the tunnels are measured. Blast holes are evenly distributed in the core area, and blast holes and energy-absorbing holes are arranged in the buffer zone. The holes are surrounded by the energy-absorbing holes, and the non-adjacent tunnels continue to be continuously blasted in a predetermined order until all the tunnels are blasted. slurry, reduce the number of blast holes and / or reduce the amount of explosives in the blast holes, non-adjacent tunnels are blasted continuously in a predetermined order and make the displacement change of surrounding rock and / or the change of surface settlement less than the predetermined threshold.

Owner:中建华东投资有限公司 +2

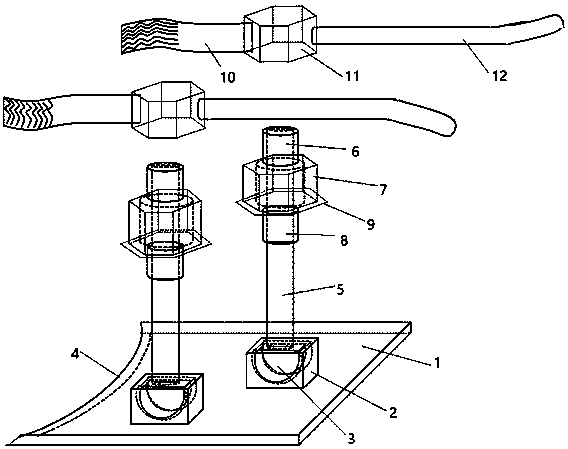

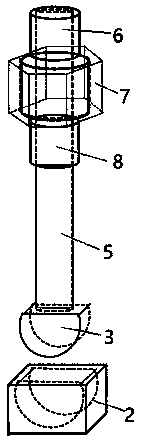

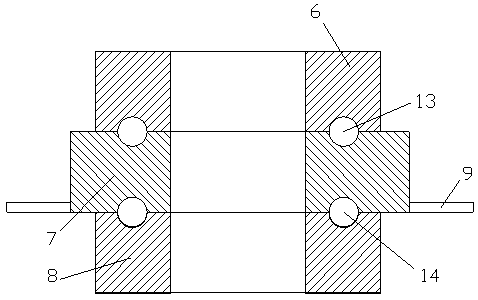

Ground-carving object pulling device

PendingCN110467134AMaintain labor motivationLifting method scienceLifting devicesHoisting equipmentsPhysical healthEngineering

The invention discloses a ground-carving object pulling device. The ground-carving object pulling device includes a pulling body, and further includes a chassis, a movable supporting mechanism, and rotating mechanisms. The movable supporting mechanism includes a left supporting mechanism and a right supporting mechanism which are symmetrically arranged and of the same structure, the left supporting mechanism or the right supporting mechanism includes a supporting column, a seat bowl and a seat cup, the bottoms of the supporting columns are connected to the seat cups, the seat cups are placed in the seat bowls, and the seat bowls are fixed to the chassis. The rotating mechanisms sleeve the supporting columns. The pulling body includes a left pulling body and a right pulling body, and an inner hexagonal snap ring is disposed in the middle of each of the left pulling body and the right pulling body, wherein the inner hexagonal snap ring of the left pulling body sleeves the rotating mechanism on the supporting column of the left supporting mechanism in a clamping mode, and the inner hexagonal snap ring of the right pulling body sleeves the rotating mechanism on the supporting column ofthe right supporting mechanism in a clamping mode. The scientific and efficient pulling of a ground-carving object is achieved, the physical health of operation personnel is effectively protected, the labor cost is saved, and the efficiency of construction operation is guaranteed.

Owner:中石化石油工程技术服务有限公司 +2

Method for extracting metal zinc powder with different purposes from zinc dross

ActiveCN102423803BAlleviate the problem of high ionsAlleviate the problem of high Cl ionsProcess efficiency improvementZinc ionHydrometallurgy

The invention relates to a method for extracting metal zinc powder with different purposes from zinc dross, in particular to a method for treating zinc dross by adopting ore grinding and dust collection equipment and metallurgical equipment as well as a metallurgical process to obtain metal zinc powder with different particle sizes and different purposes, which belongs to the cross field of the ore grinding and metallurgy technology. The method comprises the following steps: vibrating and crushing the zinc dross, and crushing and screening by using a ball grinding mill; carrying out tertiary screening on collected dust and powder dust of each pipeline; and collecting the dust by using the dust collection equipment. The invention has the advantages that the powder dust is not discharged torealize environmental friendliness; and three kinds of metal zinc powder and two kinds of residues in a return zinc smelting process are obtained only by adopting a physical crushing method, so that the recovery rate of zinc is improved, and the highly-efficient separation and the zero discharge of valuable elements are realized. The invention solves the problem of large quantity of Cl ions generated in a zinc hydrometallurgy process and simultaneously realizes the effects that the whole process is closed together with products, the zinc content of the various zinc powder is more than or equal to 98 percent, and the total recovery rate of the zinc is 99.5-100 percent.

Owner:云南云铜锌业股份有限公司

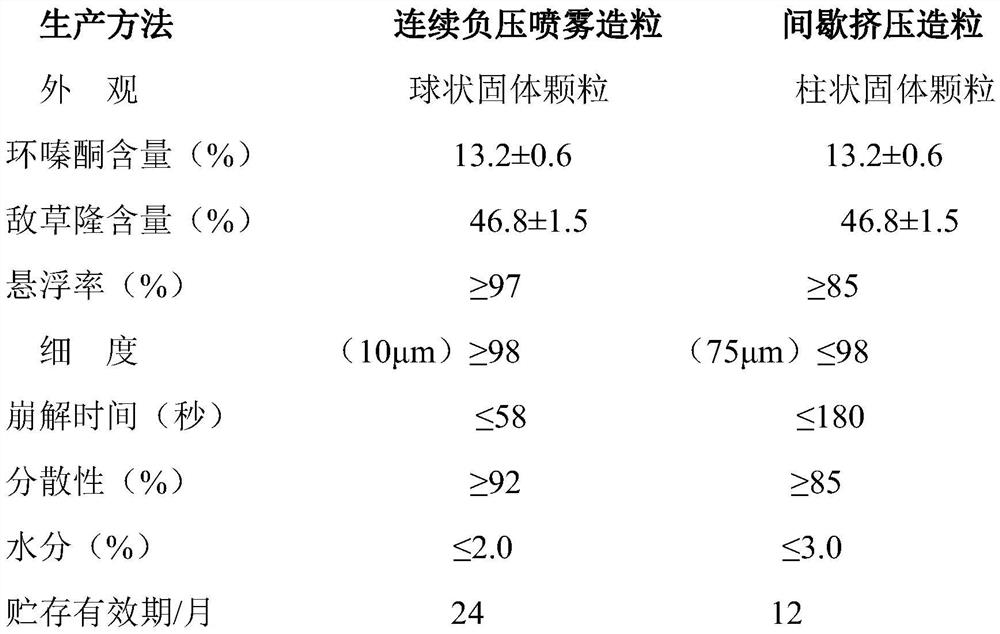

Hexazinone-diuron water-dispersible granule and clean production method thereof

PendingCN113383783ANo Spill ContaminationEasy to cleanBiocideAnimal repellantsSpray GranulationEnvironmental engineering

The invention discloses a hexazinone-diuron original medicine water-dispersible granule and a clean production method thereof. The hexazinone-diuron original medicine water-dispersible granule comprises a hexazinone original medicine, a diuron original medicine, an auxiliary agent, a carrier filler and water, wherein the content of hexazinone is 12-15%, the content of diuron is 40-48%, and all the raw materials are commercially available commodities. The clean production method comprises three steps, namely wet-process negative-pressure mixing, negative-pressure fineness crushing and negative-pressure spray granulation. The continuous clean production method of the water-dispersible granule adopts closed production in the whole process of spray drying after whole-process negative-pressure and wet-process crushing, so compared with an intermittent water-dispersible pesticide granule production line, production links are reduced, a pesticide is finer, the use efficiency of the pesticide is higher, no pesticide dust overflows, loss is greatly reduced, the production cost can be reduced, environmental pollution caused by pesticide dust and waste gas in a production process can be effectively reduced, the environmental cleanliness of a production environment is improved, the occupational health of workers can be well protected, and the utilization rate of powder can be improved.

Owner:JIANGSU RUIDONG PESTICIDE

A sinking type slag unloading system for rail inclined shafts

ActiveCN110294338BProtect occupational healthReduce casualtiesSewerage structuresUsing liquid separation agentSprinkler systemSlag

The invention discloses a sunken slag unloading system for a rail inclined shaft. The system includes a slag pool (1), a slag unloading platform (2), a trestle for passing people (3), an automatic spraying system (4), and an audible and visual alarm Device (5), sewage collection and drainage system (6), protective railing (7). The slag unloading platform (2), the trestle bridge (3) spans the slag pool (1), the protective railing (7) is arranged along the periphery of the slag pool (1), and the automatic sprinkler system (4) is fixed on the protective railing (7) , the sound and light alarm (5) is installed at the bottom of the slag unloading platform (2), and the sewage collection and drainage system (6) is set at the slope of the slag pool (1). The invention effectively solves the problems of environmental protection, energy saving and emission reduction, occupational health protection, such as sewage treatment at the slag yard at the entrance of the inclined shaft, air dust reduction, and occupational health protection, as well as the safety of personnel entering and leaving the hole and the safe operation of personnel and vehicles in the slag loading operation area at the bottom of the slag pool, etc. question.

Owner:CHINA RAILWAY NO 5 ENG GRP

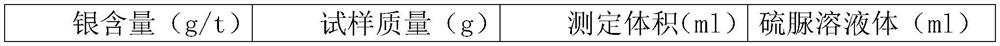

Method for rapidly determining silver content in copper ore

PendingCN114527086ALower assay costsLow costPreparing sample for investigationColor/spectral properties measurementsThioureaDissolution

The invention discloses a method for rapidly determining the content of silver in copper ore. The method comprises the steps of sample treatment, solution preparation, reaction dissolution and determination. According to the method, the thiourea medium is used for atomic absorption spectrometry measurement, and compared with an original flame atomic absorption spectrometry measurement mode, sample pretreatment is easy and convenient, the sample pretreatment difficulty is greatly reduced, the measurement time is short, harmful gas generated in the measurement process is reduced, the detection efficiency is improved, and meanwhile environmental protection is better facilitated; the variety and dosage of reagents used in the determination process are less, and the test cost is low.

Owner:湖北三鑫金铜股份有限公司

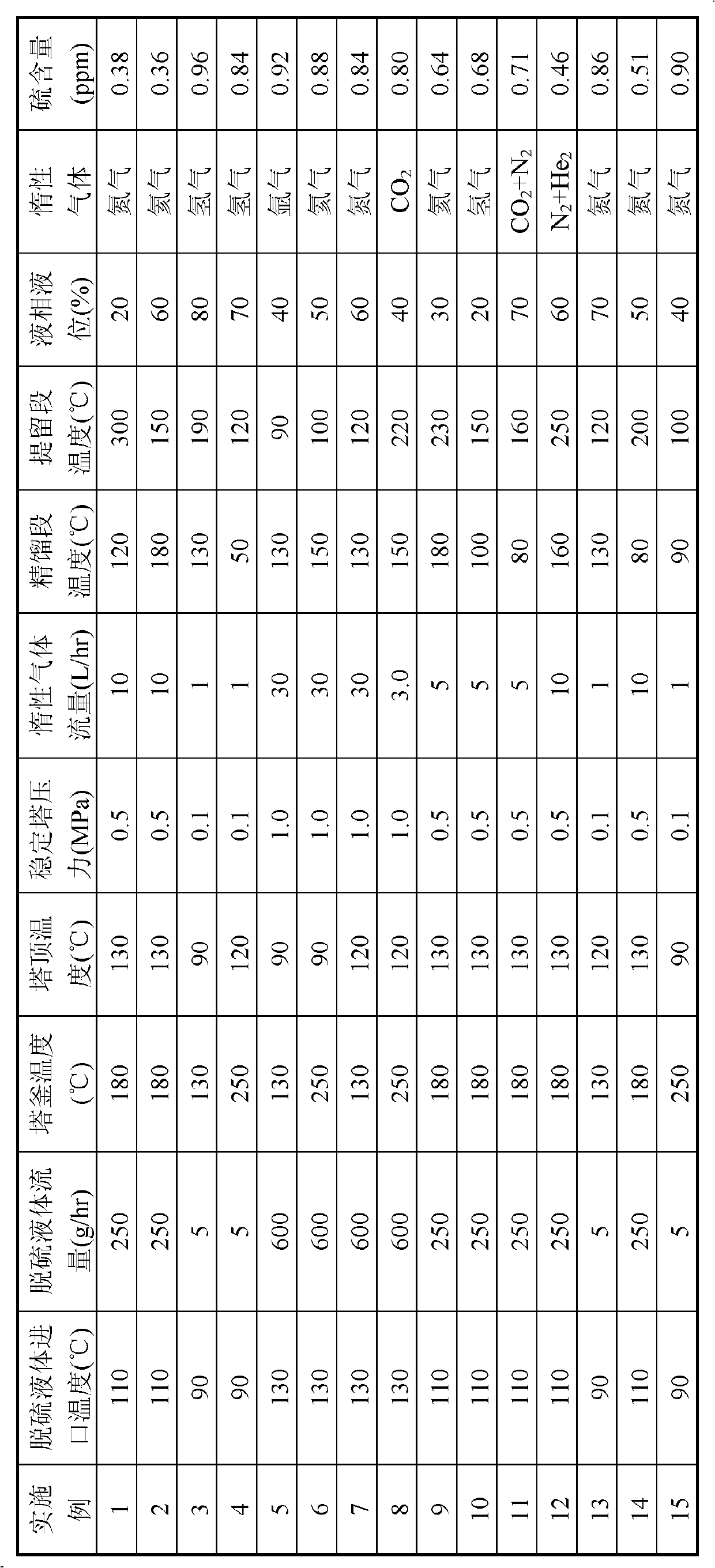

Method for determining organic sulfur in hydrodesulfurization reaction products

ActiveCN102879522AReduce analysis stepsProtect occupational healthMaterial analysisRefluxHydrodesulfurization

The invention relates to a method for determining organic sulfur in hydrodesulfurization reaction products and mainly solves the problem existing in the prior art that inorganic sulfur after continuous hydrodesulfurization catalytic reaction needs mercury scrubbing in product analysis. The method for determining organic sulfur in hydrodesulfurization reaction products comprises the following steps of: allowing an inert gas to enter a column bottom of a stabilization tower; allowing hydrodesulfurization reaction products to enter the stabilization tower from a retention section and a central section and to be heated in the column bottom of the stabilization tower, allowing heavy components in the reaction products to flow to the column bottom, allowing a gas mixture I obtained after mixing light components and the inert gas to pass through a rectifying section and flow to a reflux section; cooling the gas mixture I to reflux at the temperature which guarantees that the light components are all condensed into liquids, sending the cooled light components to the column bottom, and discharging the inert gas and a hydrogen sulfide gas from a non-condensable gas outlet of the reflux section; removing hydrogen sulfide hydrodesulfurization products, and determining organic sulfur by a sulfur determinator. By the adoption of the technical scheme, the above technical problem can be well solved. The method provided by the invention can be used in industrial application of hydrogen sulfide removal of catalytic desulfurhydrogenation reaction products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com