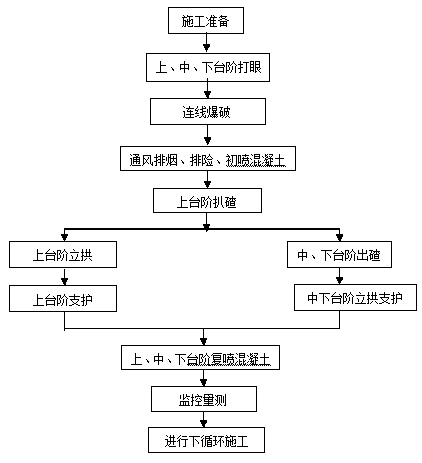

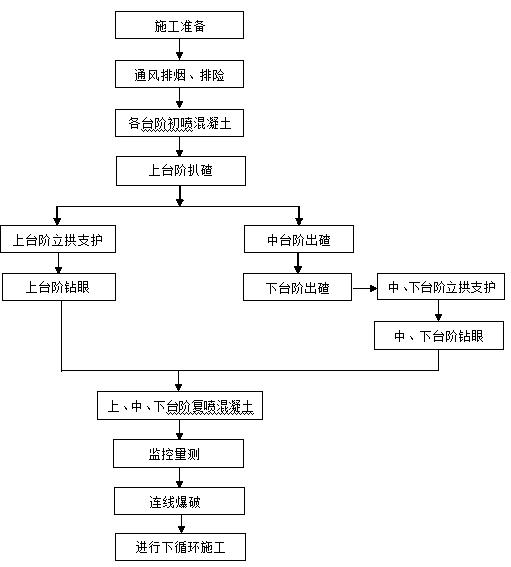

Tunnel excavation construction organization method based on three-bench method

A tunnel excavation and three-step technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of construction efficiency and safety impact, short rest time, long connection time, etc., and achieve the shortening and shortening of single-cycle construction time The effect of improving process waiting time and monthly excavation progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: The strata involved in a railway tunnel are mainly Quaternary Holocene alluvial, diluvial expansive soil, round gravel soil, pebble soil, Silurian shale, and Ordovician sandstone with gravel in the order of new and old. Interbedded rock, sandstone and shale, limestone interbedded with sandstone interbedded with shale, lower Cambrian shale interbedded with sandstone interbedded with limestone. There are no large folds and fault structures within the scope of the tunnel site, and secondary folds are relatively developed. The tunnel geology is dominated by grade IV surrounding rock, and the excavation section of the tunnel is 138m 2 . The site takes one excavation cycle in the grade IV surrounding rock area and constructs two arch frames per cycle as an example. The specific implementation methods are as follows:

[0034] Mix the excavation team and vertical arch support team into excavation support team A and excavation support team B, with 28 people in each g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com