A sinking type slag unloading system for rail inclined shafts

An inclined shaft and slag unloading technology is applied in the field of sinking slag unloading system to achieve the effects of occupational health protection, safety accident reduction, energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

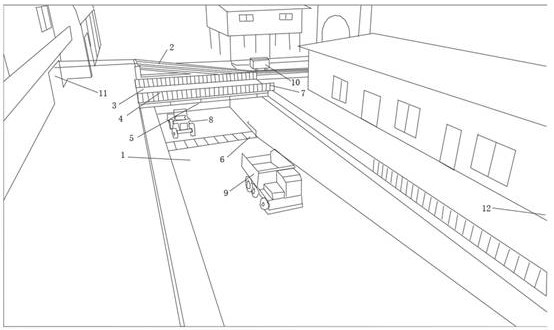

[0022] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

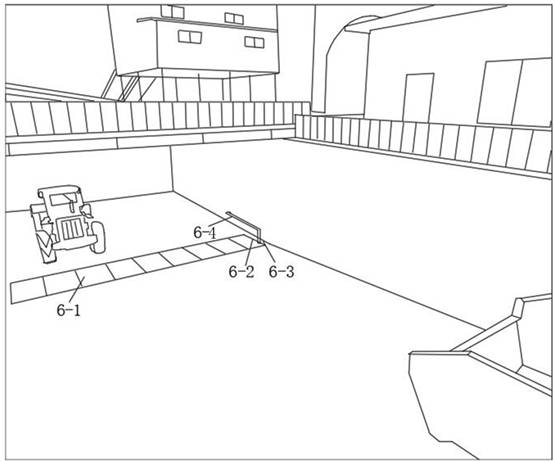

[0023] Immediately after the project enters the site, temporary road construction and site leveling at the entrance will be carried out, and then the slag pool 1 will be blasted and excavated according to the pre-designed position and size, and the side wall protection and bottom leveling construction of the slag pool 1 will be improved. Excavate a horizontal water collection ditch 6-1 at the slope position of the slag pool 1, set a water collection well 6-2 at one end, install a sewage pump 6-3 in the well, and pump the sewage to the sewage treatment pool 12 in time through the sewage pipe 6-4 Centralized processing. The top of the slag pool 1 utilizes I-beams to set up a slag unloading platform 2 and a trestle 3 for passing people according to the design, and finally installs a protective railing 7, an automatic sprinkler system 4 and an audible and visual ala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com