Horizontal bagging machine

A horizontal, bagging machine technology used in the field of conveying machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

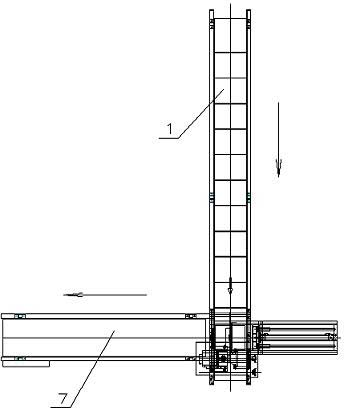

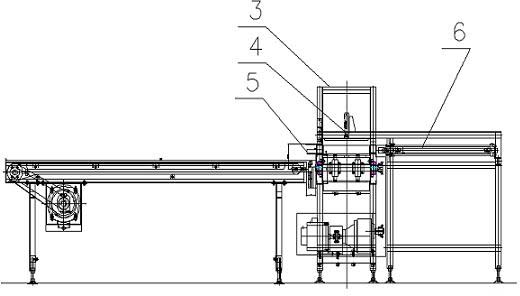

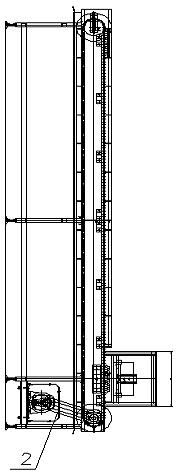

[0024] Such as Figure 1-Figure 14 As shown, the horizontal bagging machine of the present invention includes a mesh belt conveyor 1, a motor drive mechanism 2, a steel skeleton frame 3, a cylinder leveling mechanism 4, a cylinder supporting bag mechanism 5, a cylinder horizontal pushing mechanism 6 and a belt Circular operation conveying mechanism 7, motor drive mechanism 2 is installed at the end of the bagging machine, steel skeleton frame 3 is installed on the mesh belt conveyor 1, cylinder leveling mechanism 4 and cylinder horizontal pushing mechanism 6 are installed on the steel skeleton On the frame 3, the belt circulation conveying mechanism 7 is vertically connected with the mesh belt conveyor 1. The cylinder bag supporting mechanism 5 includes an upper bag supporting cylinder 8 and a lower bag supporting cylinder 9. The bagging machine is driven by a servo motor installed at the end Mechanism 2: Modular mesh belt conveyor 1 with baffles. The cylinder leveling mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com