An arc-shaped rubber fender, its preparation method and manufacturing equipment

A rubber fender and arc-shaped technology, which is applied in the direction of shipping equipment, climate change adaptation, etc., can solve the problems of fender manufacturers such as no profit margin, low mold reuse rate, and failure to be popularized, etc., to achieve simple structure, elastic The effect of large and large deformation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

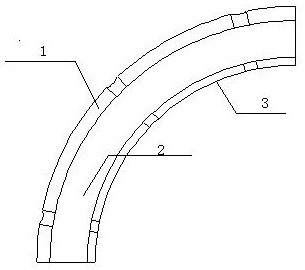

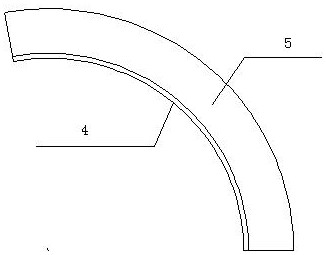

[0042] The technical solution provided in this embodiment is: an arc-shaped rubber fender, which is an arc-shaped hollow structure as a whole, including a rubber layer and a through hole; fit.

[0043] Wherein, the bottom surface is arc-shaped, the radius and radian are adjustable, and the bottom surface is provided with mounting holes.

[0044] Wherein, the radius of its bottom surface is 1-2 meters, and the radian is 60°-90°.

[0045] Wherein, the cross-sections of the rubber fender and the through hole are D-shaped; the D-shape is curved at the upper part, vertical at the middle and horizontal at the bottom.

[0046] The preparation method of the above-mentioned arc-shaped rubber fender comprises the following steps:

[0047] Step 1: Mix the raw materials according to the proportion, put them into the internal mixer for mixing, and obtain the primary glue;

[0048] Step 2: put the initial rubber into the extruder to obtain a semi-formed rubber; the discharge port of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com