A wavy sealing retaining ring combined rotary dynamic sealing structure

A technology of rotating sealing structure and sealing retaining ring, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of large mechanical seal structure, high processing requirements of parts, complex oil seal structure, etc. The effect of using requirements and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention relates to a rotary motion shaft sealing structure for a gear seawater pump of a thermal power torpedo power system. The present invention will be further described now in conjunction with accompanying drawing.

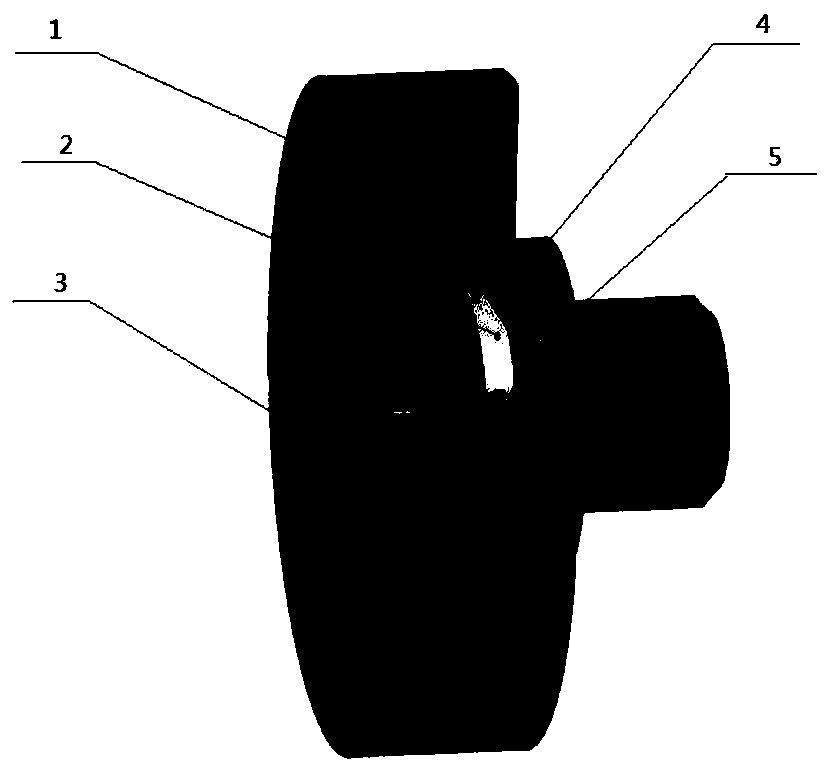

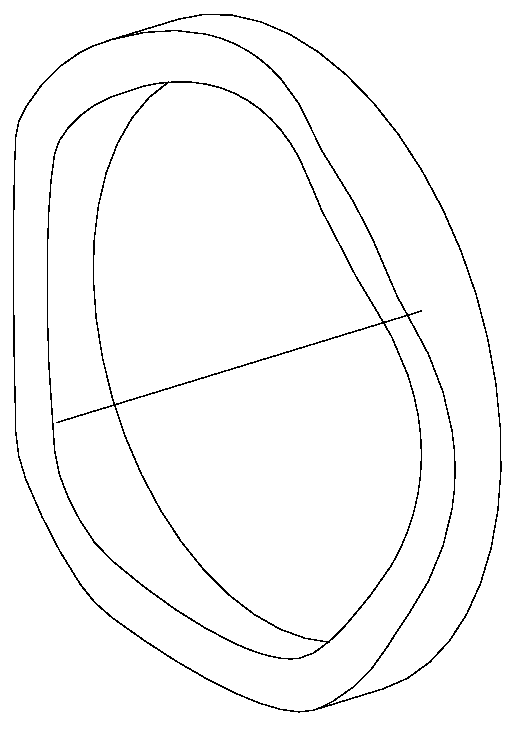

[0016] The invention belongs to a combination rotary shaft dynamic sealing structure of a wave-shaped sealing retaining ring and an O-shaped sealing ring. as attached figure 1 As shown, it mainly consists of a wear-resistant, low-friction polymer retaining ring 2 and a standard rubber O-ring 5. Taking a typical gear pump application as an example, the high-speed rotating shaft 3 is supported by bearings on the pump casing 1 and protrudes from the hole of the pump casing 1 at the same time. The retaining ring 2 and the O-ring 5 are installed in the stepped hole of the housing 1 . The high pressure fluid is on the O-ring 5 side. In order to facilitate the installation and initial positioning of the O-ring 5, a retaining ring 4 needs to be provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com