Self-centering pre-stressed concrete framework floor slab structure

A concrete and prestressed technology, applied in the direction of floors, building components, building structures, etc., can solve the problems of destroying the self-centering ability of beam-column joints of self-centering prestressed frames, affecting the seismic performance of the overall structure, and reducing artificial Low cost, low structural cost, and the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

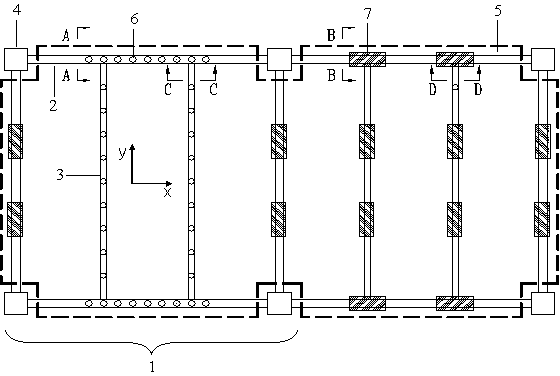

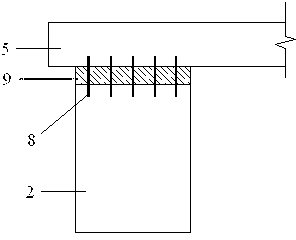

[0015] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings.

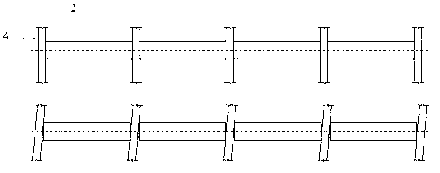

[0016] Such as Figures 1 to 6 As shown, a self-centering prestressed concrete frame floor structure of the present invention, the concrete frame floor structure includes N horizontally arranged spans 1, N is an integer greater than 1, for example, N can be 2, 3 or 4. exist figure 2 Among them, N is 2. Each span 1 includes four main beams 2, M secondary beams 3, where M is an integer greater than 1, four frame columns 4 and a floor 5. The main beam 2 is connected between two adjacent frame columns 4 through prestressed steel strands, and the main beam 2 and the frame columns 4 form a rectangular frame. The secondary beams 3 are connected between two opposite main beams 2 . The floor 5 is located above the main beam 2 and the secondary beam 3 . In one span 1, the number of secondary beams 3 is determined according to the actual ne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap