Large-diameter steel strand compression type anchorage device

A technology of extruded anchors and steel strands, which is applied to structural elements, building components, building reinforcements, etc., can solve the problem of not being able to anchor large-diameter 1×19 structural steel strands, etc., to improve the anchoring performance, increase the High friction and gripping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

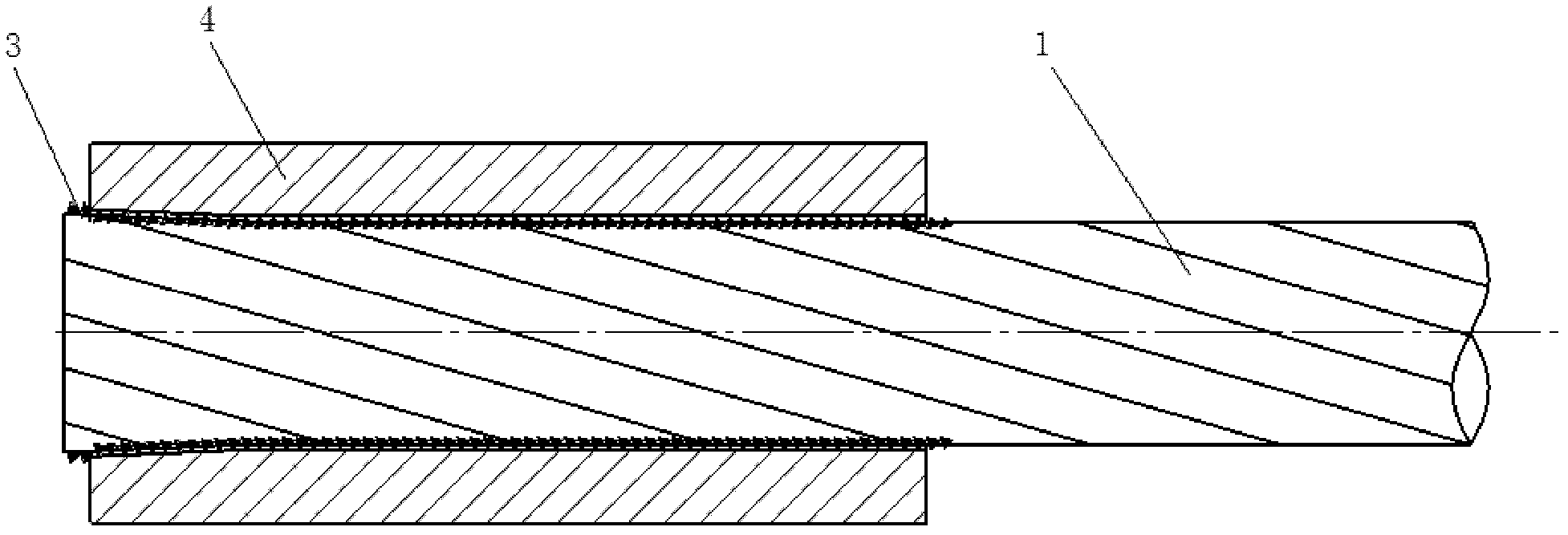

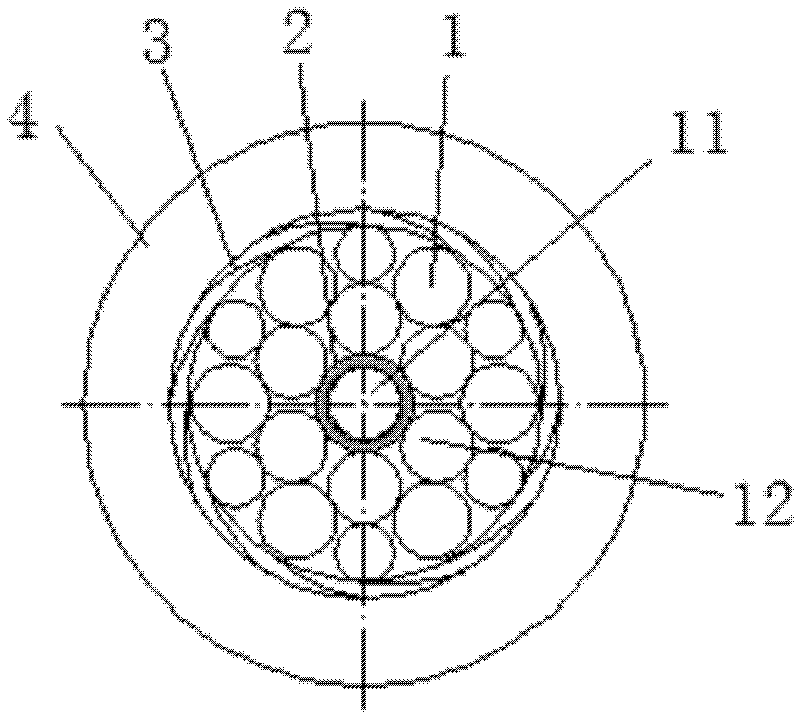

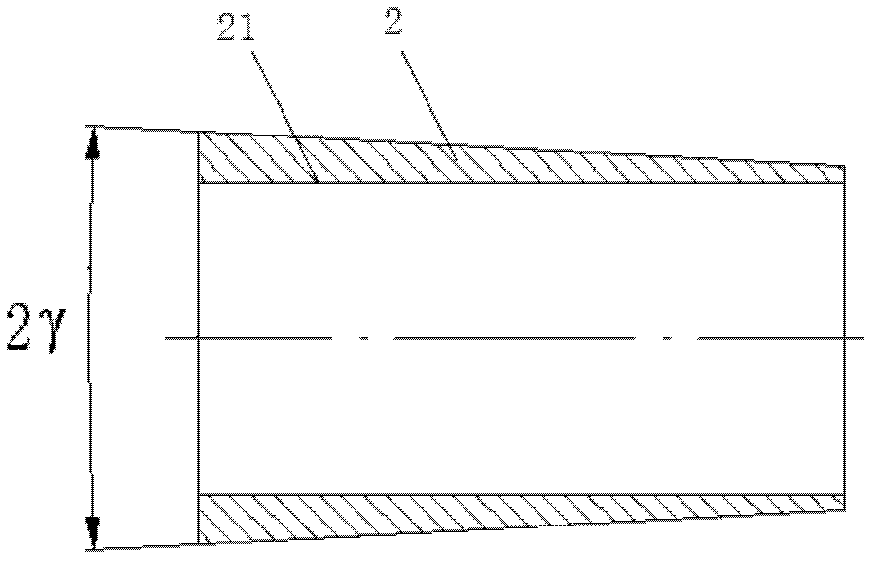

[0019] Such as figure 1 , figure 2 Shown, the present invention comprises a steel strand 1, and steel strand 1 is the 1 * 19 structural steel strands sold on the market, and a tapered sleeve 2 is wedged in the center of steel strand 1 one end (as figure 2 , image 3 shown), the conical angle of the outer conical surface of the conical sleeve 2 is 2γ=6°, and the conical angle can vary within the range of 5° to 7°; the inner wall of the conical sleeve 2 is a circular through hole 21, and the conical sleeve 2 is arranged between the central steel wire 11 and the outer steel wire 12 of the steel strand 1.

[0020] Such as figure 1 , Figure 4 As shown, a special-shaped steel wire bushing 3 is arranged on the outer wall of the steel strand 1. The special-shaped steel wire bushing 3 is wound with high-hardness special-shaped steel wire 31. The cross-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com