Process for making a glass brick and brick obtained by said process

A block and glass plate technology, applied to building materials, etc., can solve the problem that the isolation ability of known blocks is not completely satisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

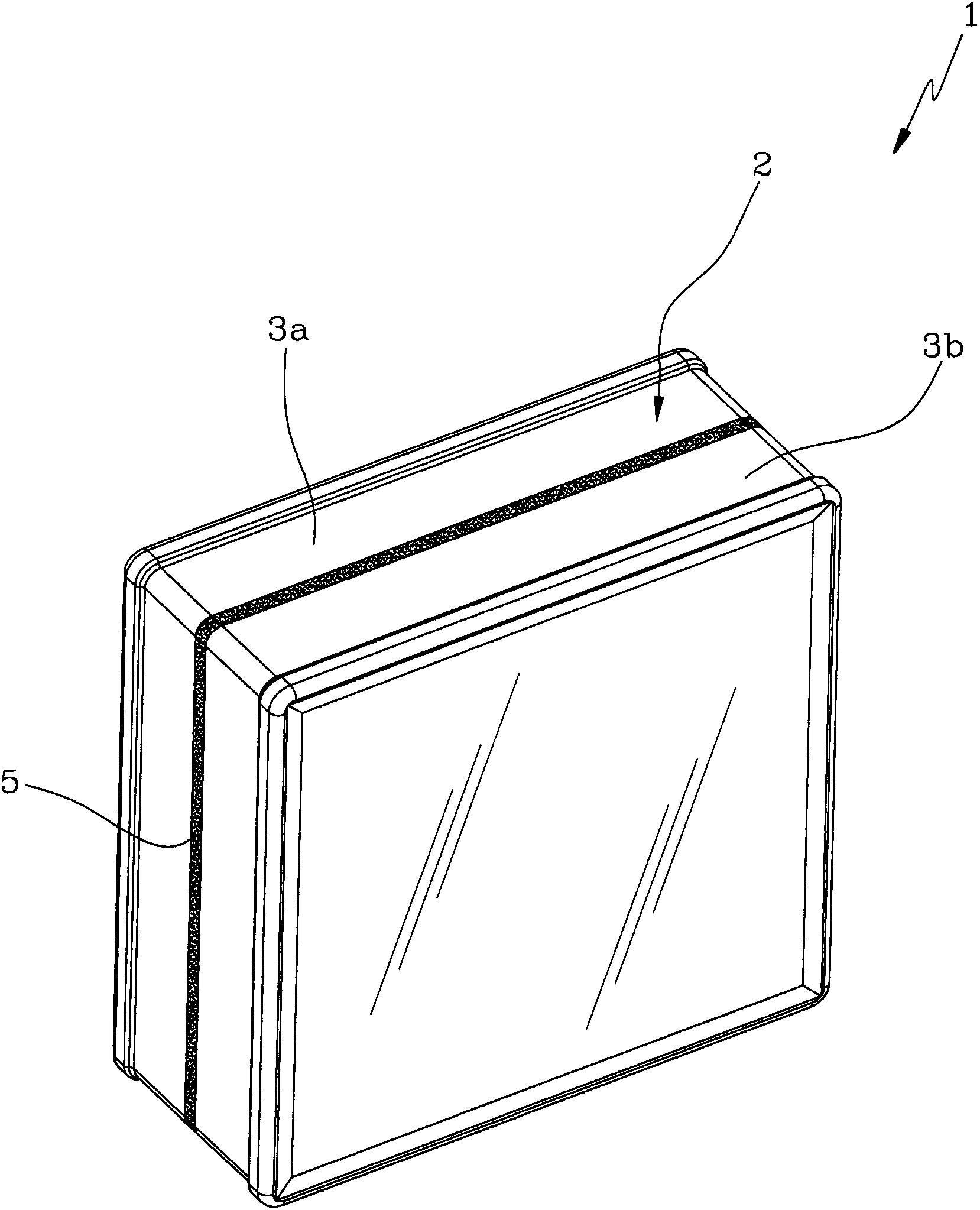

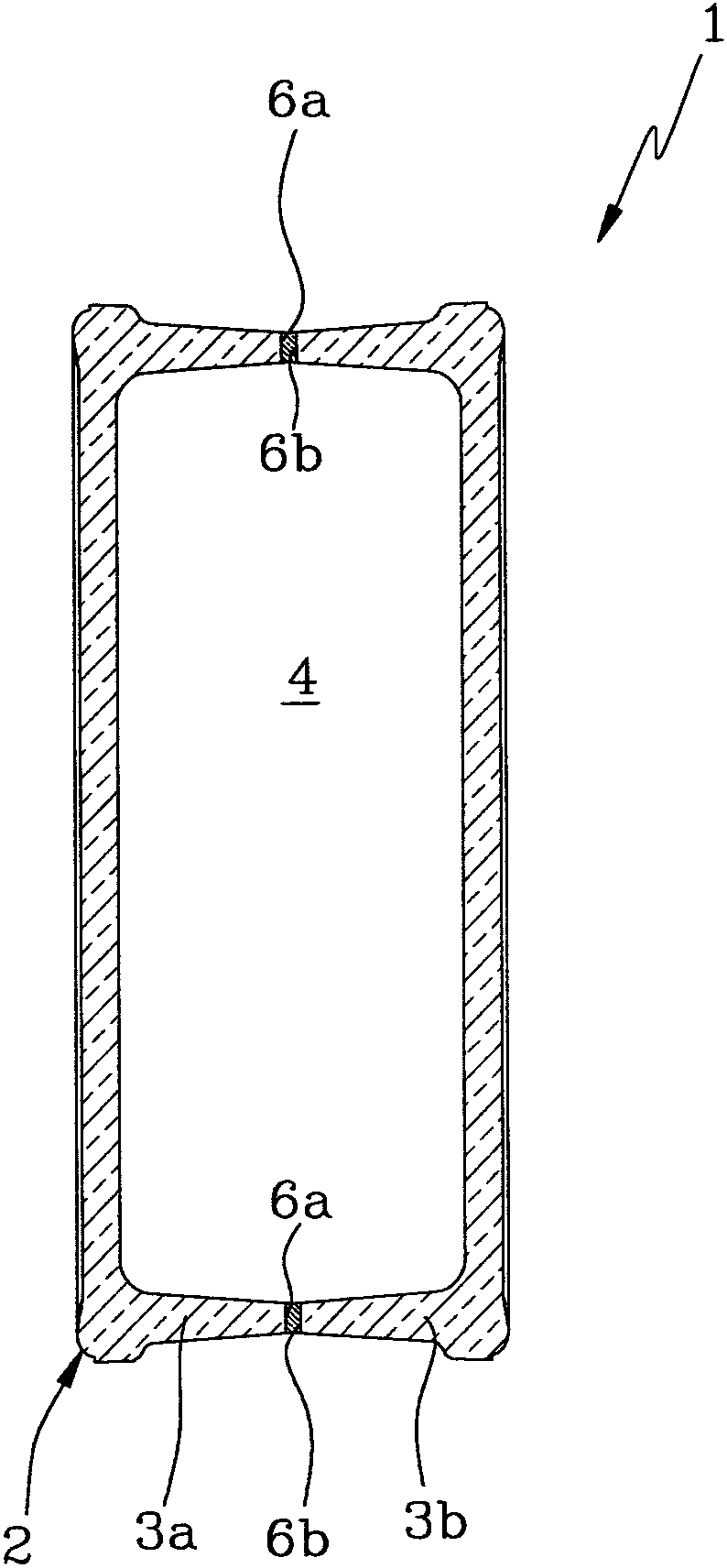

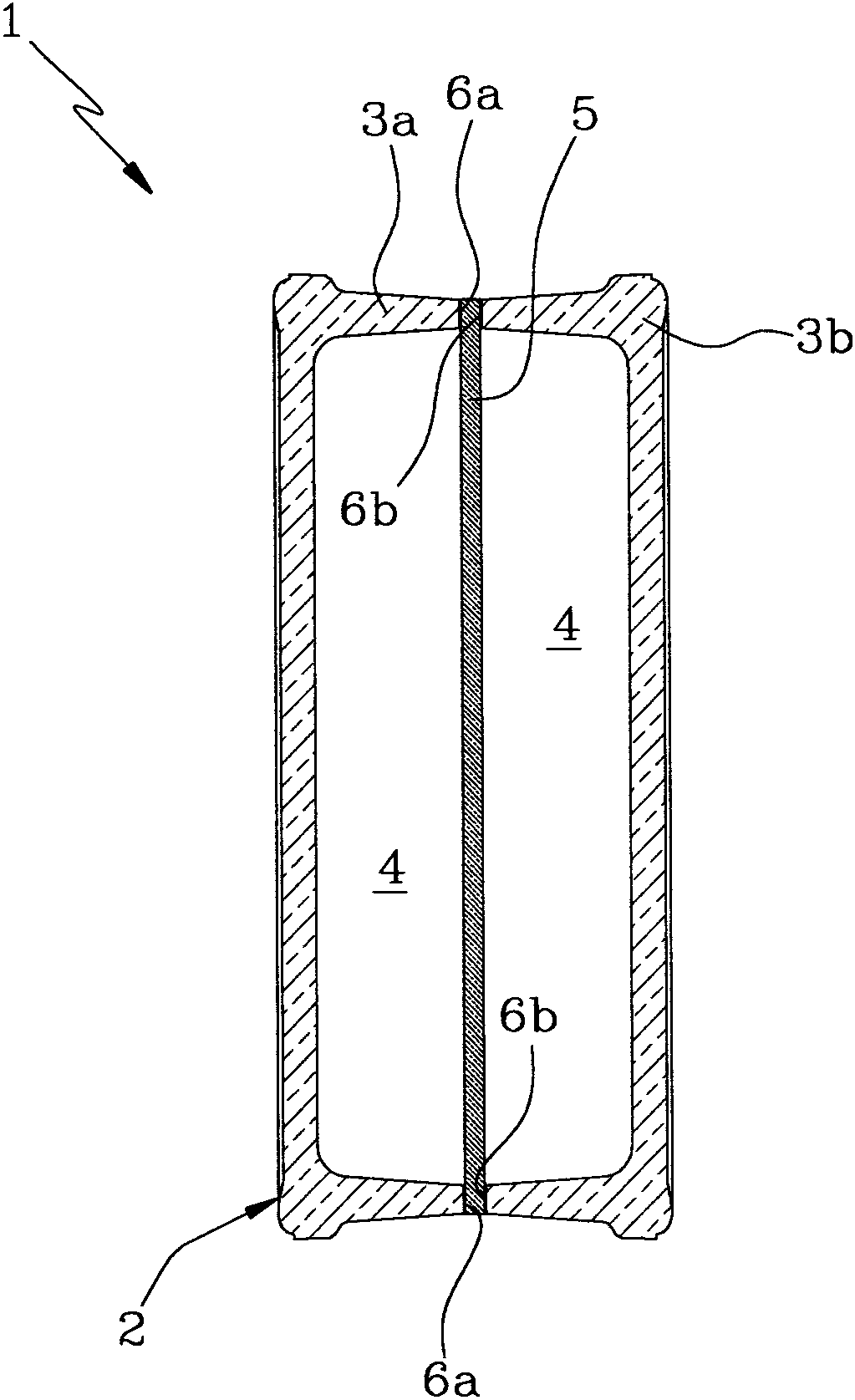

[0018] In the figures, the reference number 1 designates as a whole a glass block according to the invention. The block 1 comprises a body 2 made of transparent material. Preferably, this material is glass.

[0019] Advantageously, the body 2 has a substantially parallelepiped shape with a square base.

[0020] In an alternative embodiment (not shown), the body 2 has a substantially parallelepiped shape with a rectangular base.

[0021] In a further embodiment (not shown), such a body 2 may have, for example, a prismatic shape with a polygonal base.

[0022] The body 2 comprises at least two half-shells 3 a , 3 b coupled to each other so as to define the same body 2 .

[0023] The half-shells 3a, 3b are fixed to each other in a manner described in more detail below.

[0024] In particular, the half-shells 3a, 3b are shaped in such a way that once coupled to each other they define a closed cavity 4 inside the body 2 ( figure 2 ).

[0025] Advantageously, cavity 4 is fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com