Continuous automatic aluminum-plastic separation system

A separation system, automatic aluminum technology, applied in the direction of recycling technology, solid waste removal, electronic waste recycling, etc., can solve land pollution, waste of aluminum and plastic, air pollution and other problems, achieve recycling, high degree of automation , the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

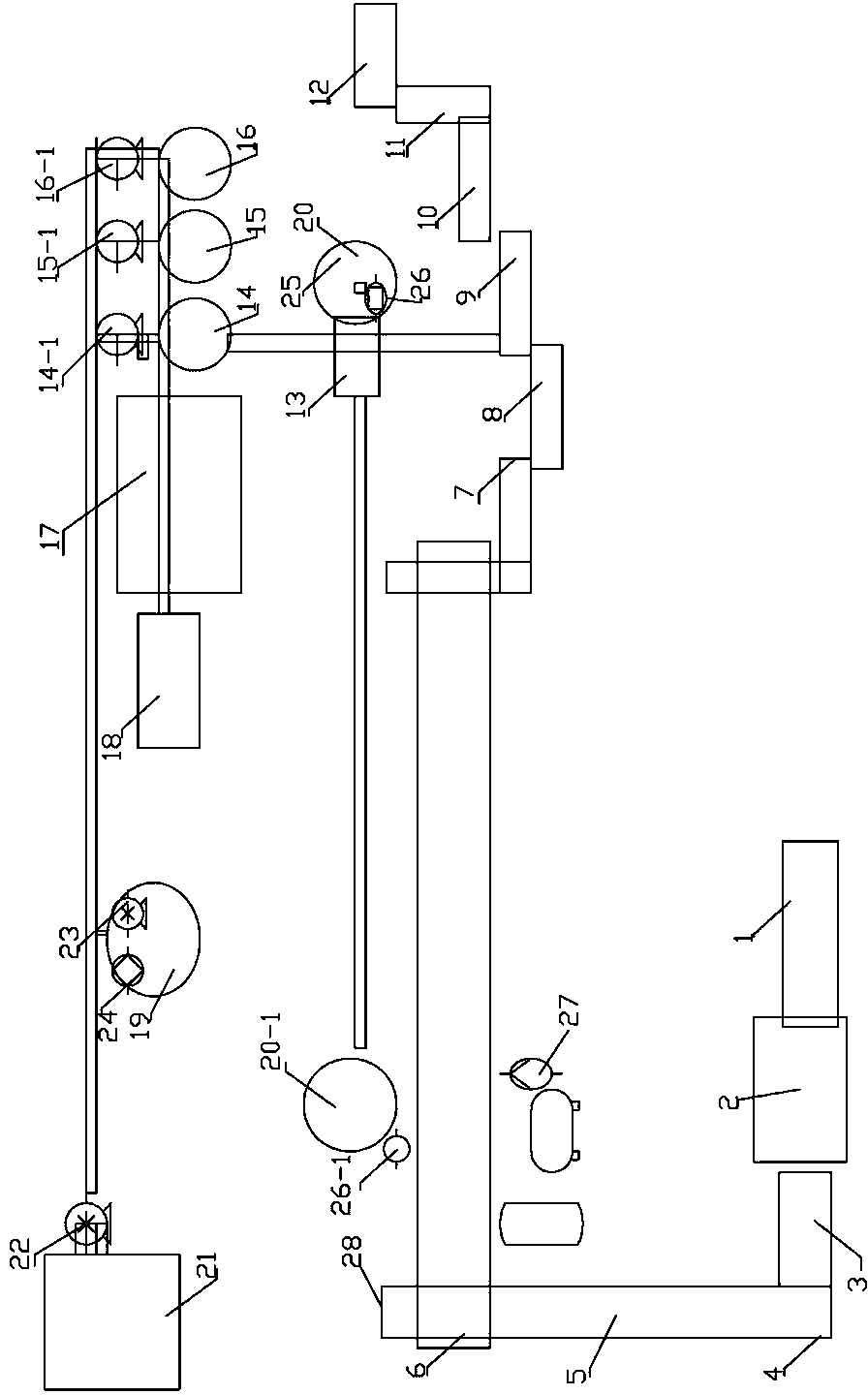

[0007] Such as figure 1 As shown, the continuous automatic aluminum-plastic separation system includes a water storage tank 21, a clean water pump 22, a reuse water pump 23, a sewage pump 24, a backwater pool 19, an electrical control room 17, a hot water pump 27, and a feeding conveyor belt Disperser 2, Disperser connected with inclined conveyor belt 3, Inclined conveyor belt connected with homogenizer 4, homogenizer connected with sorting table 5, sorting table connected with reactor 6, reactor connected with feeder 7, feeder Connect dry centrifuge 8, dry centrifuge connect wet centrifuge 9, the plastic film that wet centrifuge separates through rinsing pool 10, rubbing machine 11, squeeze dry machine 12 granulation. The other line of the wet centrifuge connects the centrifugal filter 13 again, and the centrifugal filter connects the No. 1 purification pond 14, the No. 2 purification pond 15, and the No. 3 purification pond 16, and the purification pond is respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com