System and method for recycling waste emulsified cutting fluid

A technology of cutting fluid and stock solution, which is applied in the field of waste emulsified cutting fluid recycling system, can solve the problems that the waste emulsified cutting fluid cannot be recycled and processed, and the processing effect is not good, and achieve simple and effective recycling processing and increase effective filtration Area, the effect of solving the problem of silting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

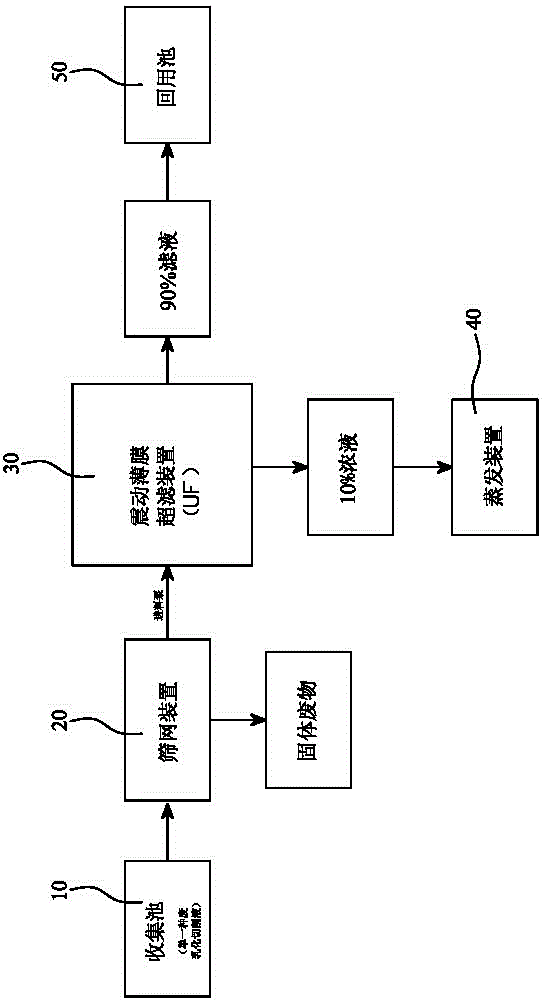

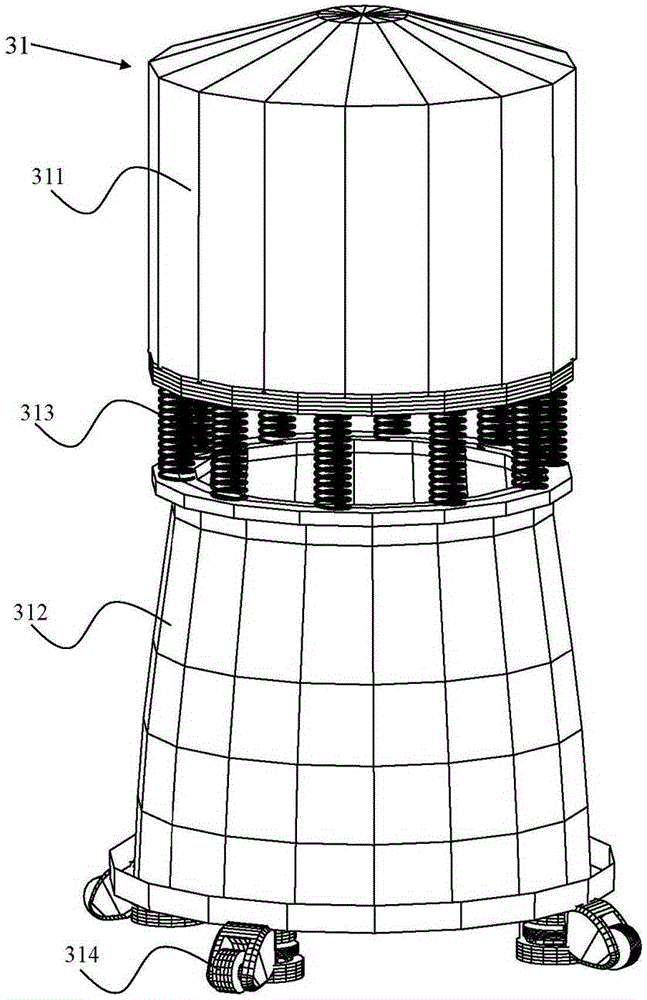

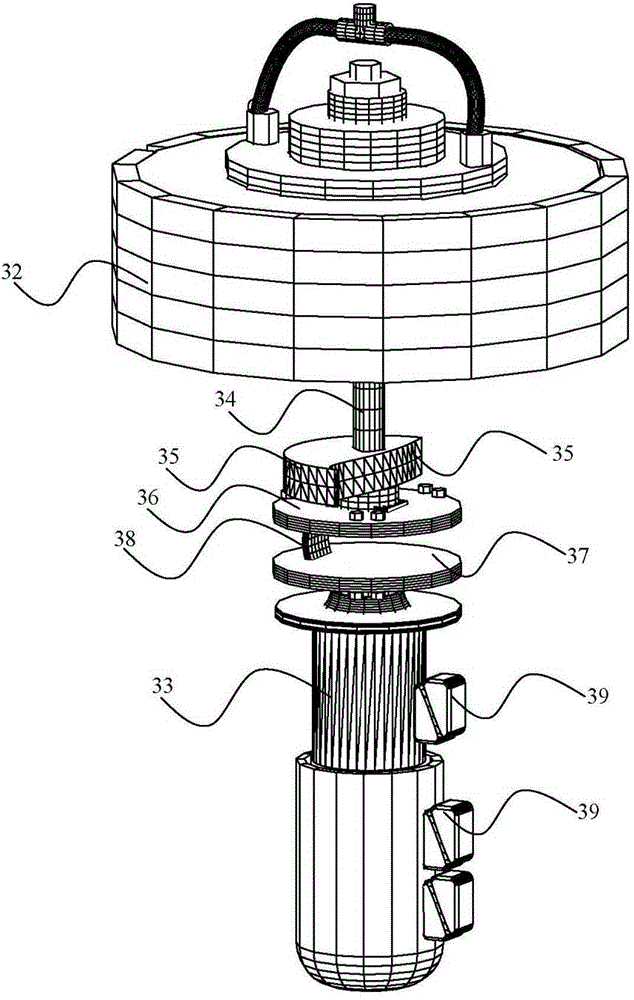

[0071] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a collection tank 10 , a screen device 20 , a vibrating membrane ultrafiltration device (UF) 30 , an evaporation device 40 and a reuse tank 50 .

[0072] Among them, such as figure 1 As shown, the collection pool 10 is used to collect a single waste emulsified cutting fluid. In the process of machining waste emulsified cutting fluid, various waste emulsified cutting fluids are processed separately, and a single waste emulsified cutting fluid is input into the collection pool. 10 in.

[0073] The screen device 20 is used to filter a single waste emulsified cutting fluid to remove solid waste. The input port of the screen device 20 is connected to the output port of the aforementioned collection tank 10, and the solid waste obtained by filtering through the screen device 20 is Exhaust outward.

[0074] The vibrating membrane ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com