Heat exchange system and method for continuous wastewater treatment in biosafety laboratory

A heat exchange system and wastewater treatment technology, applied in pathogenic microorganism wastewater treatment, heat exchange equipment, heating water/sewage treatment, etc., can solve the problems of laboratory economic loss, large energy loss, pipeline scaling, etc. The effect of leakage of pathogenic microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

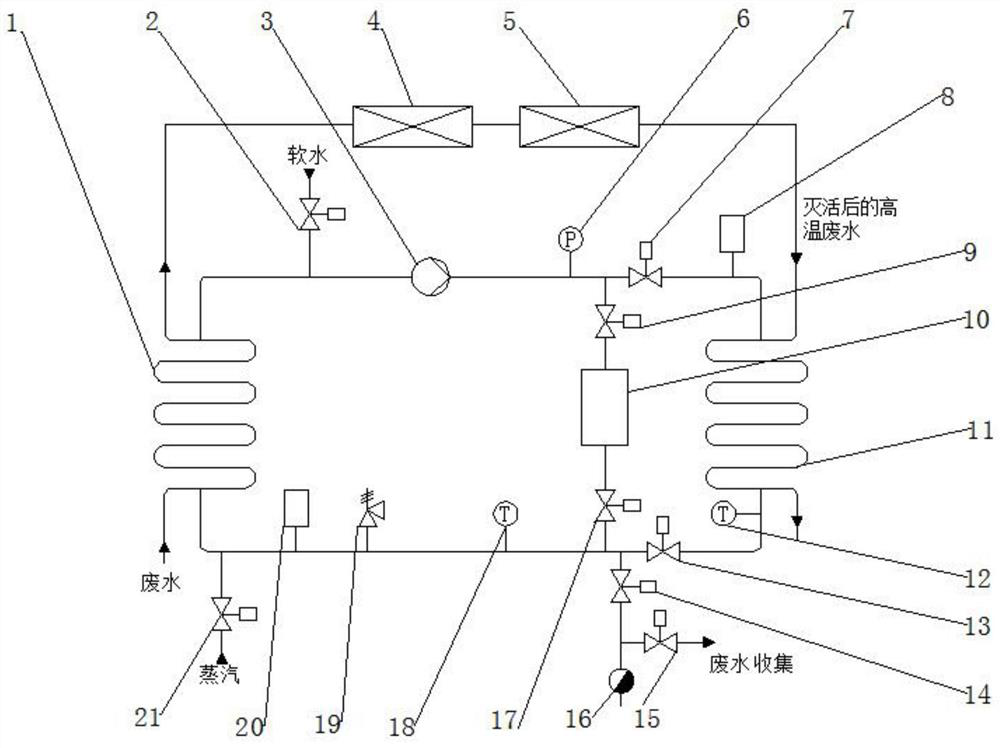

[0027] see figure 1 , a heat exchange system for continuous wastewater treatment in a biosafety laboratory, comprising a double-layer casing heat exchanger-1 located at the waste water inlet and a valve-2 at the soft water injection port, the double-layer casing heat exchanger- The double-layer casing on 1 is divided into internal pipes and external pipes;

[0028] The inner pipeline of the double-layer casing heat exchanger-1 is fixedly connected to the inlet pipeline of the heating device 4 through a stainless steel pipeline, and the outlet pipeline of the heating device 4 is fixedly connected to the inlet pipeline of the heat preservation coil 5 through a stainless steel pipeline, so The outlet pipe of the thermal insulation coil 5 is fixedly connected with the inner pipe of the double-layer casing heat exchanger 11 through a stainless steel pipe, and the water outlet of the inner pipe of the double-layer casing heat exchanger 11 is connected with the waste water discharge ...

Embodiment 2

[0043] According to the heat exchange system for continuous waste water treatment in the biosafety laboratory of embodiment 1, this embodiment provides a disinfection method for the heat exchange system, the method includes: closing valve one 2, opening valve two 7, valve three 9, Valve four 13, valve five 14, valve six 15, valve seven 17, valve eight 21, through steam pressure, soft water is discharged to waste water collection tank. After a certain period of time, after the soft water has been drained, the intermittent switch valve 5 14, the intermittent switch method is to close the valve 5 14, open the valve for 5 and a half seconds every 30 seconds, and drain the condensed water in the pipeline, thereby disinfecting the heat exchange system deal with.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com