A kind of preparation method of high-purity EGCG

A high-purity, mass-concentration technology, applied in the field of high-purity EGCG preparation, can solve the problems of low recovery rate of EGCG, unsuitable for industrial production, high price, etc., and achieves strong controllability of technical indicators, easy industrial production, and industrialization. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

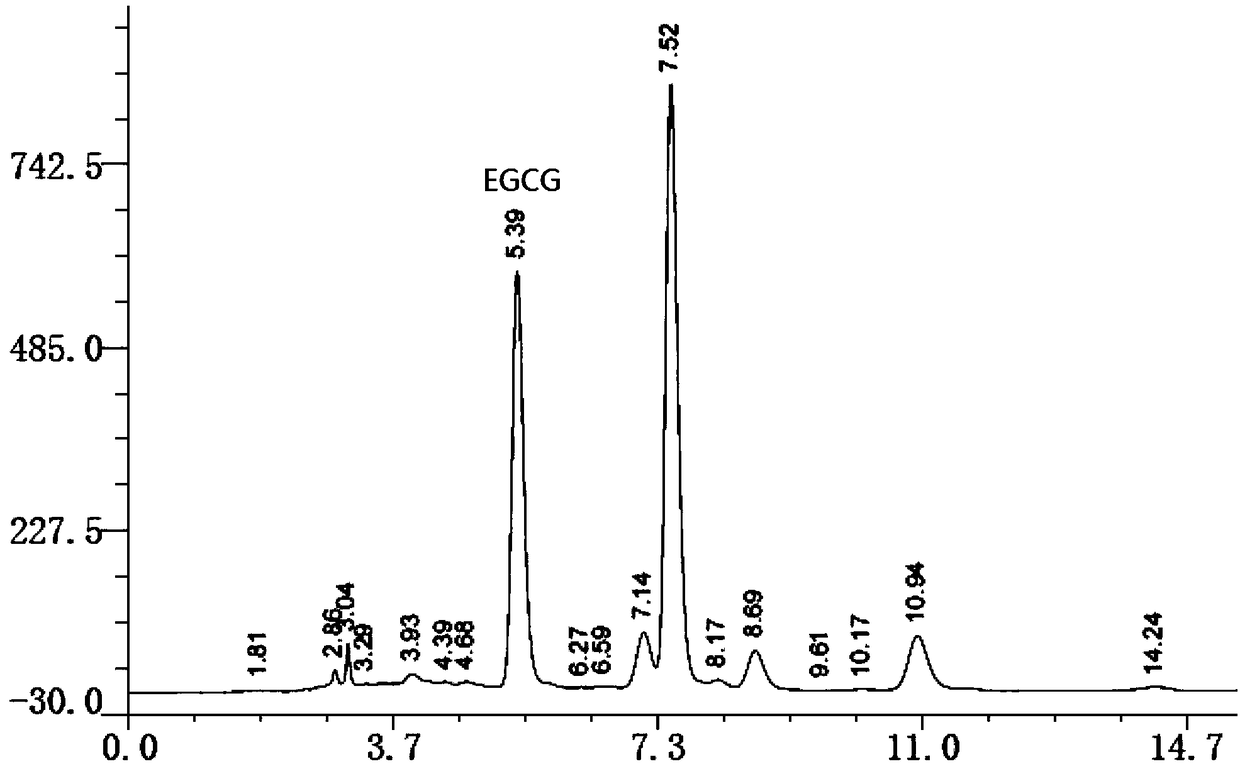

Image

Examples

Embodiment 1

[0030] A preparation method for high-purity EGCG, comprising the following steps:

[0031] (1) Using commercially available tea polyphenols (with an EGCG content of 29.93%) as raw materials, dissolve them in ethanol with a mass concentration of 10% until the dry matter content is 10%, to obtain a tea polyphenol solution;

[0032] (2) Pass the tea polyphenol solution through a chromatographic column filled with HZ-818 non-polar macroporous adsorption resin, first elute with pure water after pretreatment, then elute with 30% ethanol, and collect the eluate and concentrated to a dry matter content of 40%, to obtain a concentrated eluate;

[0033] (3) The concentrated eluent is separated by a three-component simulated moving bed, connected end to end by 15 chromatographic columns, with HZ-818 macroporous adsorption resin as the separation carrier, and the flow pump is controlled by the central control device, computer, and PLC program , flowmeter, and solenoid valve to select and...

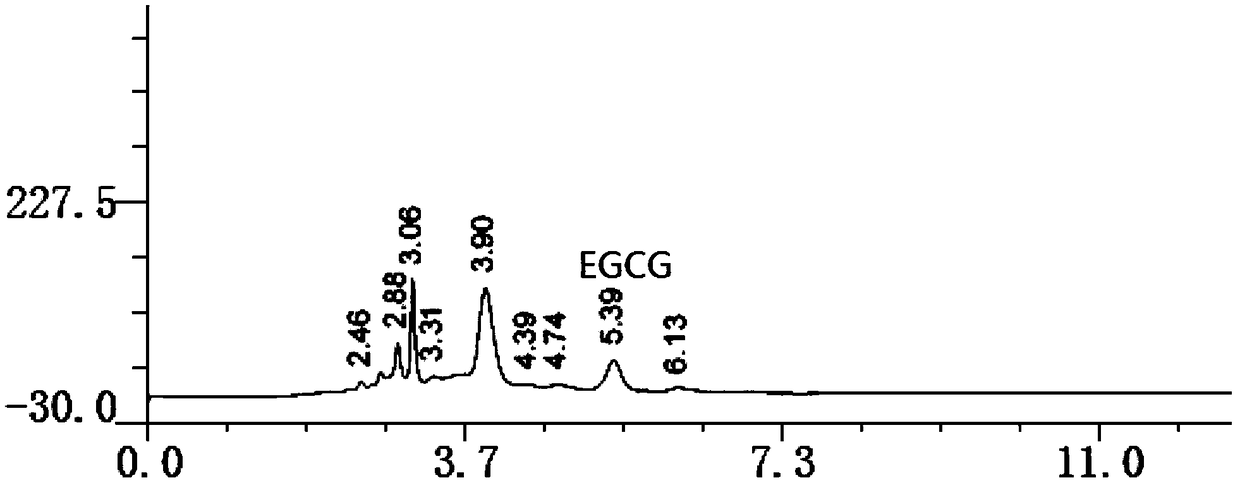

Embodiment 2

[0047] A preparation method for high-purity EGCG, comprising the following steps:

[0048] (1) Commercially available tea polyphenols (with an EGCG content of 54.12%) were used as raw materials, dissolved in ethanol with a mass concentration of 10% until the dry matter content was 10%, to obtain a tea polyphenol solution;

[0049] (2) Pass the tea polyphenol solution through a chromatographic column filled with HZ-818 non-polar macroporous adsorption resin, first elute with pure water after pretreatment, then elute with 30% ethanol, and collect the eluate and concentrated to a dry matter content of 40%, to obtain a concentrated eluate;

[0050] (3) The concentrated eluent is separated by a three-component simulated moving bed, connected end to end by 15 chromatographic columns, with HZ-818 macroporous adsorption resin as the separation carrier, and the flow pump is controlled by the central control device, computer, and PLC program , flowmeter, and solenoid valve to select an...

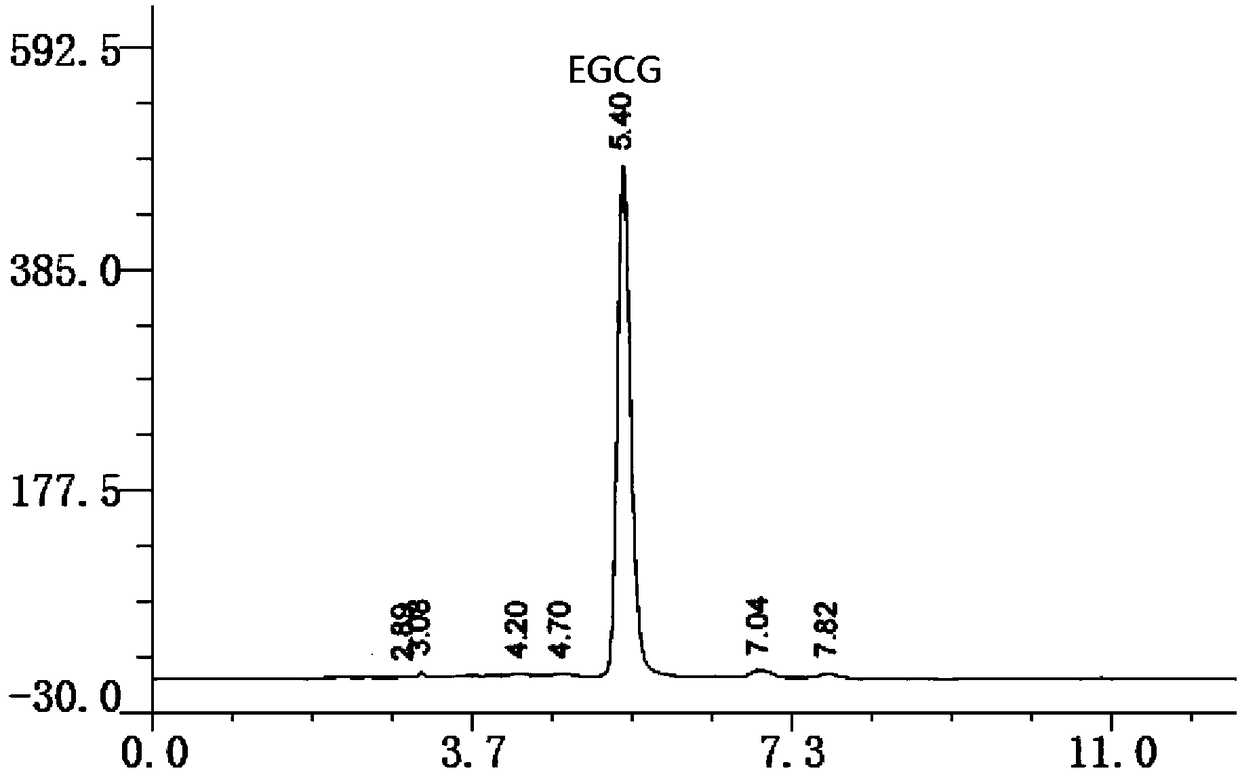

Embodiment 3

[0052] A preparation method for high-purity EGCG, comprising the following steps:

[0053] (1) Commercially available tea polyphenols (with an EGCG content of 29.93%) were used as raw materials, dissolved in ethanol with a mass concentration of 10% until the dry matter content was 30%, to obtain a tea polyphenol solution;

[0054] (2) Pass the tea polyphenol solution through a chromatographic column filled with HZ-816 non-polar macroporous adsorption resin, first elute with pure water after pretreatment, then elute with 30% ethanol, and collect the eluate and concentrated to a dry matter content of 30%, to obtain a concentrated eluate;

[0055] (3) The concentrated eluent is separated by a three-component simulated moving bed, connected end-to-end by 10 chromatographic columns, with HZ-816 macroporous adsorption resin as the separation carrier, and the flow pump is controlled by the central control device, computer, and PLC program , flowmeter, and solenoid valve to select an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com