Device and method for continuously preparing biological crude oil

A bio-crude oil and stirring device technology, which is applied in the preparation of liquid hydrocarbon mixtures, the treatment of hydrocarbon oil, and the petroleum industry. It can solve the problems of not being suitable for biomass, short continuous operation time, and high pressure in pipelines, etc., to achieve The effect of improving the safety of the experiment, improving the level of safety technology, and strong anti-blocking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

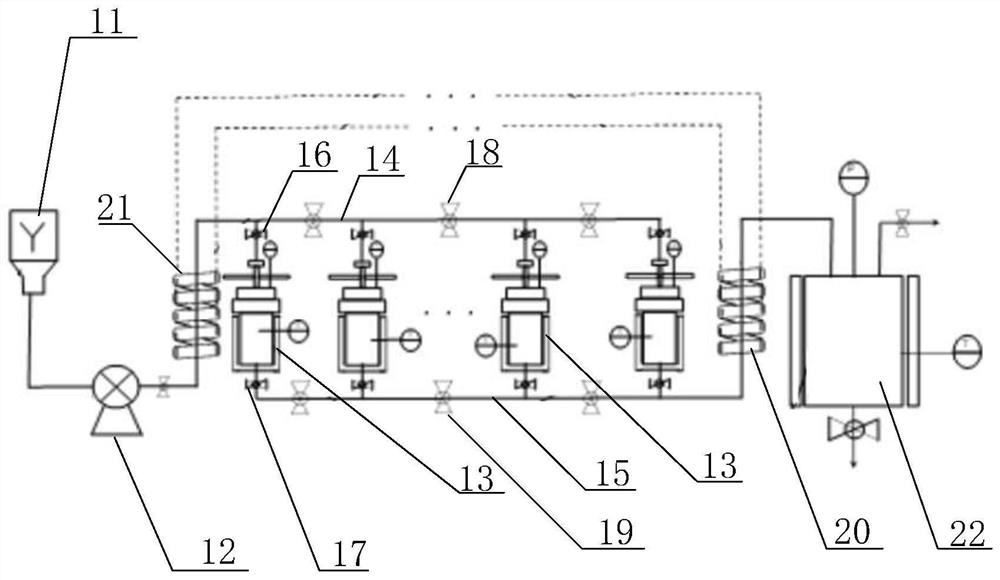

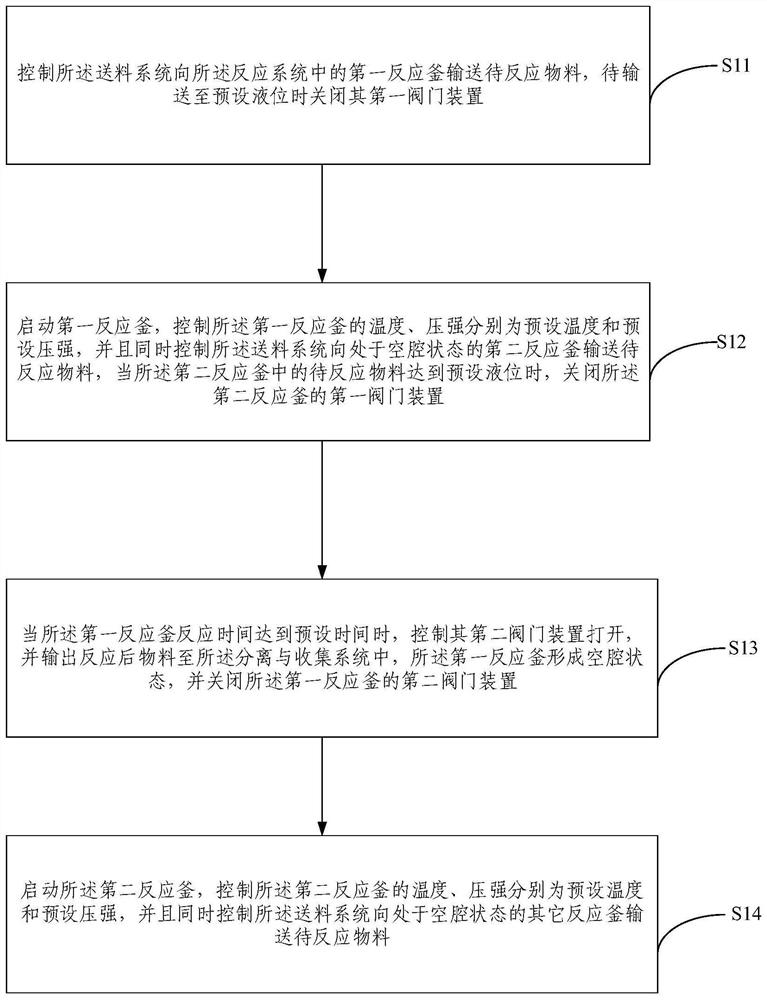

[0087] Set relevant parameters: feed rate 10ml / min, reactor volume 100ml, feeding volume 50ml, 11 reactors (numbered 1-11 reactors according to feeding order), reaction temperature 300°C, heating rate 15 ℃ / min, reaction time 30min;

[0088] System action execution process: Livestock and poultry manure is used as the raw material, and the material is fed by the feeding system. First, the No. 1 reactor is controlled to feed 50ml, and it is heated for 20 minutes to reach the reaction temperature of 300°C. At this time, 4 reactions of No. 2-5 The kettle was filled with material (50ml). The reaction time is 30min, and the time period is full of No. 6-No. 11 reactors. When the reaction time is reached, the second valve device 17 below the No. 1 reactor is opened to discharge the material. After the discharge is completed, the second valve device 17 is closed. And open the first valve device 16, No. 1 reactor feed, open the second valve device 17 when No. 2 reactor reaches reaction ...

Embodiment 2

[0090] Set relevant parameters: feed rate 20ml / min, reactor volume 200ml, feed volume half of reaction volume 100ml, 8 reactors, reaction temperature 280°C, heating rate 20°C / min, reaction time 20min;

[0091] System action execution process: Fiber materials such as corn stalks are used as raw materials, and the materials are fed by the feeding system. First, 100ml is fed into the No. 1 reactor, and it is heated for 14 minutes to reach a reaction temperature of 280°C. At this time, No. 2 and No. 3 2 reactors have been filled with material (100ml), and reactor No. 4 is 4 / 5 full (80ml). The reaction time is 20min. During this time period, the 4 reactors numbered 4-7 and the reactor No. 8 are full of 4 / 5 (80ml), and the reactor No. 8 continues to feed. When the reaction time is reached, the reactor No. 1 reacts The second valve device 17 below the kettle is opened automatically and carries out discharging, and after discharging finishes, the second valve device 17 closes and open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com