Multistage protein separation and collection equipment with improved structure

A protein separation and collection equipment technology, applied in the field of medical protein separation and purification, can solve problems such as difficult to achieve effective and high-purity separation, and achieve the effects of compact structure, improved separation efficiency, and increased separation solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

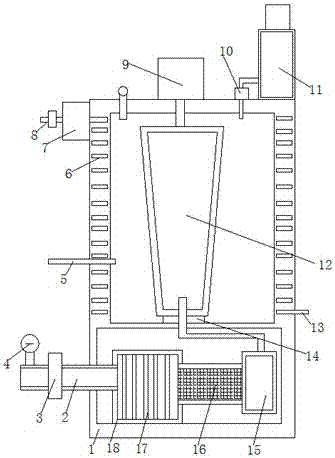

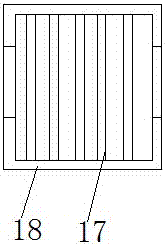

[0017] Embodiment: Start the first pump body 15 and the heater 7, the heater 7 heats the liquid in the S-shaped circulation pipeline 6, heats the liquid in the housing 1, and the first pump body 15 passes the mixed protein solution through the The material pipe 2 enters the filter device 18, and the protein solution is filtered by a plurality of filter membranes 17 on the filter device 18. After filtering, it is filtered again through the chromatography column 16, and after the filter is completed, it enters the drum 12 through the first pump body 15. The motor 9 drives the drum 12 to rotate, and centrifugally filters the mixed protein solution. After centrifugation, the mixed protein solution forms bubbles and enters the collection box 11 through the second pump body 10, and is cooled and condensed by a refrigeration device, and the mixed protein solution waste liquid passes through The waste liquid collection pipe 5 is discharged, and universal wheels can be installed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com