A kind of preparation method and application of corrosion-resistant super-hydrophobic stainless steel mesh

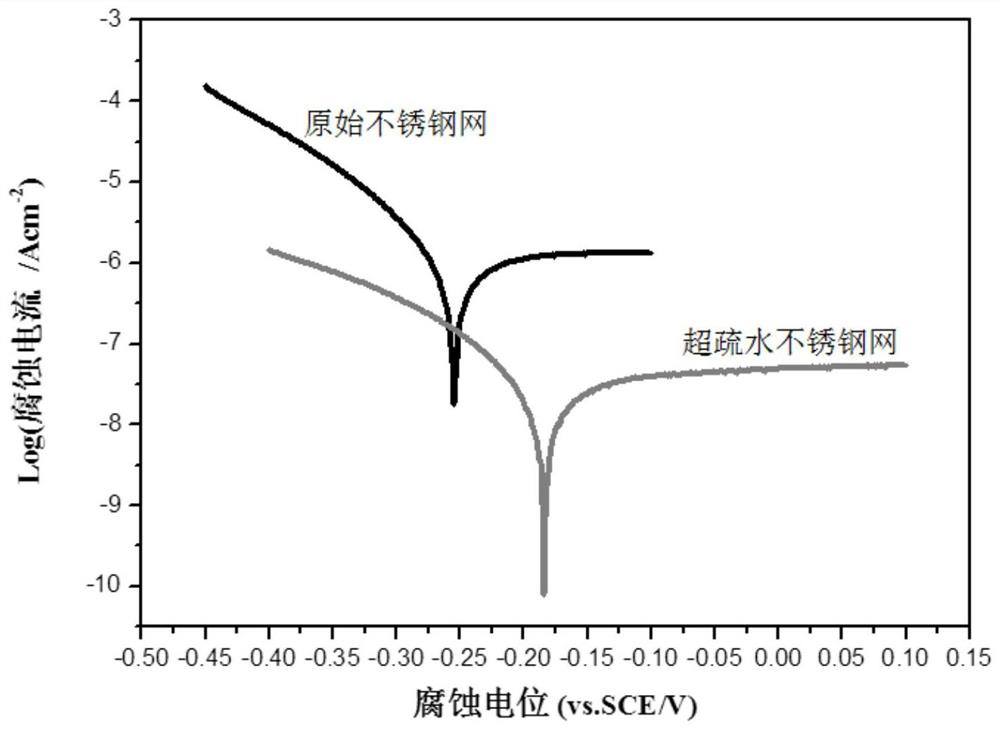

A technology of stainless steel mesh and corrosion resistance, which is applied in the field of material preparation, can solve the problems of being unsuitable for large-scale industrial production, restricting market application, and long preparation cycle, etc., achieving excellent superhydrophobic and superlipophilic capabilities, and facilitating large-scale batches The effect of optimized production, continuous and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

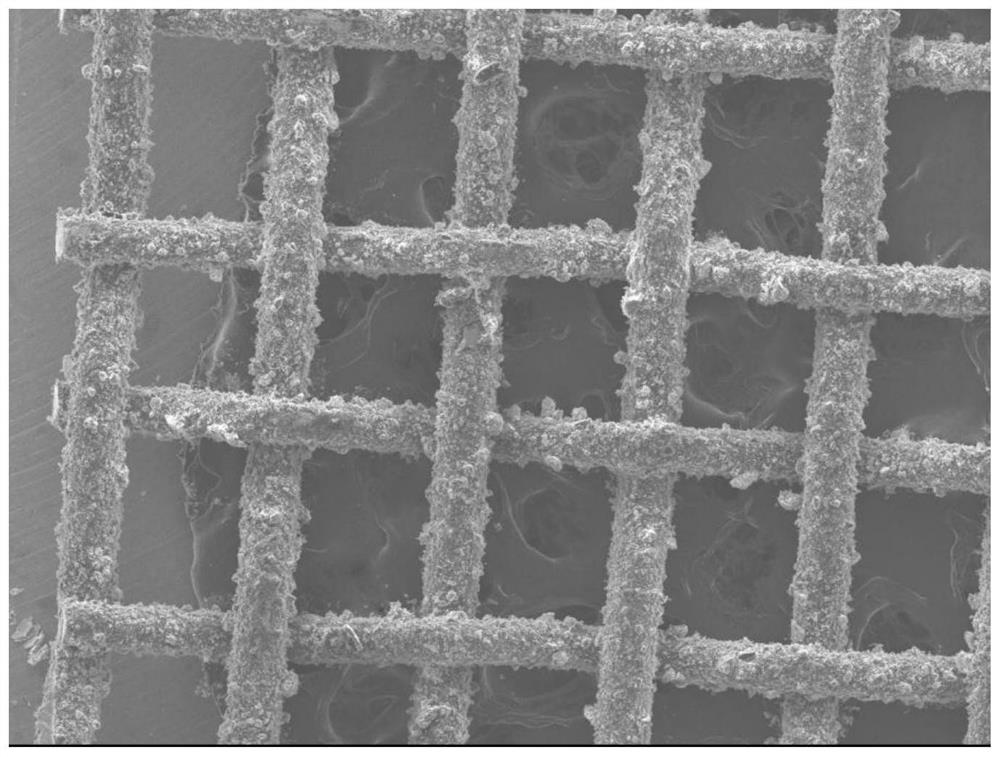

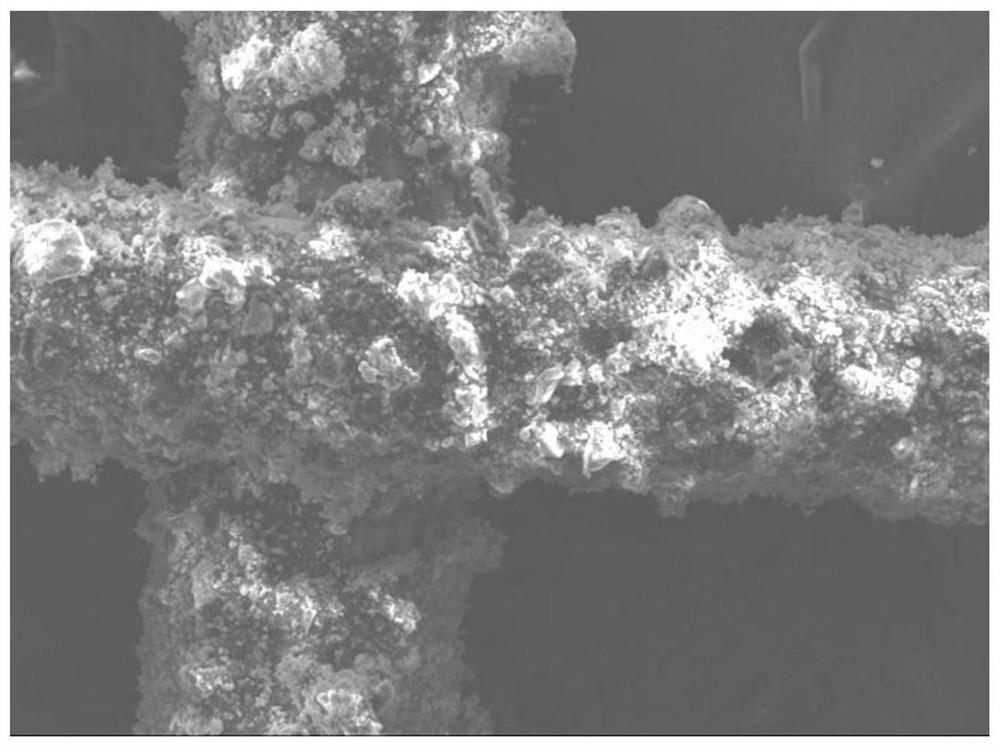

[0049] A kind of preparation method of corrosion-resistant superhydrophobic stainless steel mesh of the present invention, specifically implement according to the following steps:

[0050] Step 1: Clean the surface of the stainless steel mesh with ethanol and water ultrasonically for 5 minutes, then blow dry it with cold wind or dry it naturally at room temperature to obtain a clean stainless steel mesh;

[0051]Step 2: Ultrasonically clean the fly ash with ethanol and water for 5 minutes in sequence, place the cleaned fly ash in a drying oven at 50°C to dry, then crush the dried fly ash and pass through a 100-mesh sieve;

[0052] Step 3: Disperse the fly ash in a stearic acid solution with a mass percentage of 1%, filter the surface after 6 hours of surface modification at room temperature, dry in a drying oven at 50°C, pulverize and pass through a 100-mesh sieve after complete drying, Obtain modified fly ash;

[0053] Step 4: Prepare an acetone solution of epoxy resin E44 a...

Embodiment 2

[0055] A kind of preparation method of corrosion-resistant superhydrophobic stainless steel mesh of the present invention, specifically implement according to the following steps:

[0056] Step 1: Clean the surface of the stainless steel mesh with ethanol and water ultrasonically for 5 minutes, then blow dry it with cold wind or dry it naturally at room temperature to obtain a clean stainless steel mesh;

[0057] Step 2: ultrasonically clean the fly ash with ethanol and water for 5 minutes in sequence, place the cleaned fly ash in a drying oven at 60°C to dry, then crush the dried fly ash and pass through a 150-mesh sieve;

[0058] Step 3: Disperse the fly ash in a stearic acid solution with a mass percentage of 2%, filter the surface after 4 hours of surface modification at room temperature, dry in a drying oven at 60°C, pulverize and pass through a 150-mesh sieve after complete drying, Obtain modified fly ash;

[0059] Step 4: Prepare an acetone solution with a mass percent...

Embodiment 3

[0061] A kind of preparation method of corrosion-resistant superhydrophobic stainless steel mesh of the present invention, specifically implement according to the following steps:

[0062] Step 1: Clean the surface of the stainless steel mesh with ethanol and water ultrasonically for 5 minutes, then blow dry it with cold wind or dry it naturally at room temperature to obtain a clean stainless steel mesh;

[0063] Step 2: ultrasonically clean the fly ash with ethanol and water for 5 minutes in turn, place the cleaned fly ash in a drying oven at 70°C to dry, then crush the dried fly ash and pass through a 200-mesh sieve;

[0064] Step 3: Disperse the fly ash in a stearic acid solution with a mass percentage of 3%, filter the surface after 3 hours at room temperature, place it in a drying oven at 70°C, dry it, pulverize it after it is completely dry, and pass it through a 200-mesh sieve. Obtain modified fly ash;

[0065] Step 4: Prepare an acetone solution with a mass percentage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com