Held gear wire clipper

A technology of wire cutters and gears, which is applied in the field of pliers to achieve the effects of accurate action, light structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described by utilizing the accompanying drawings.

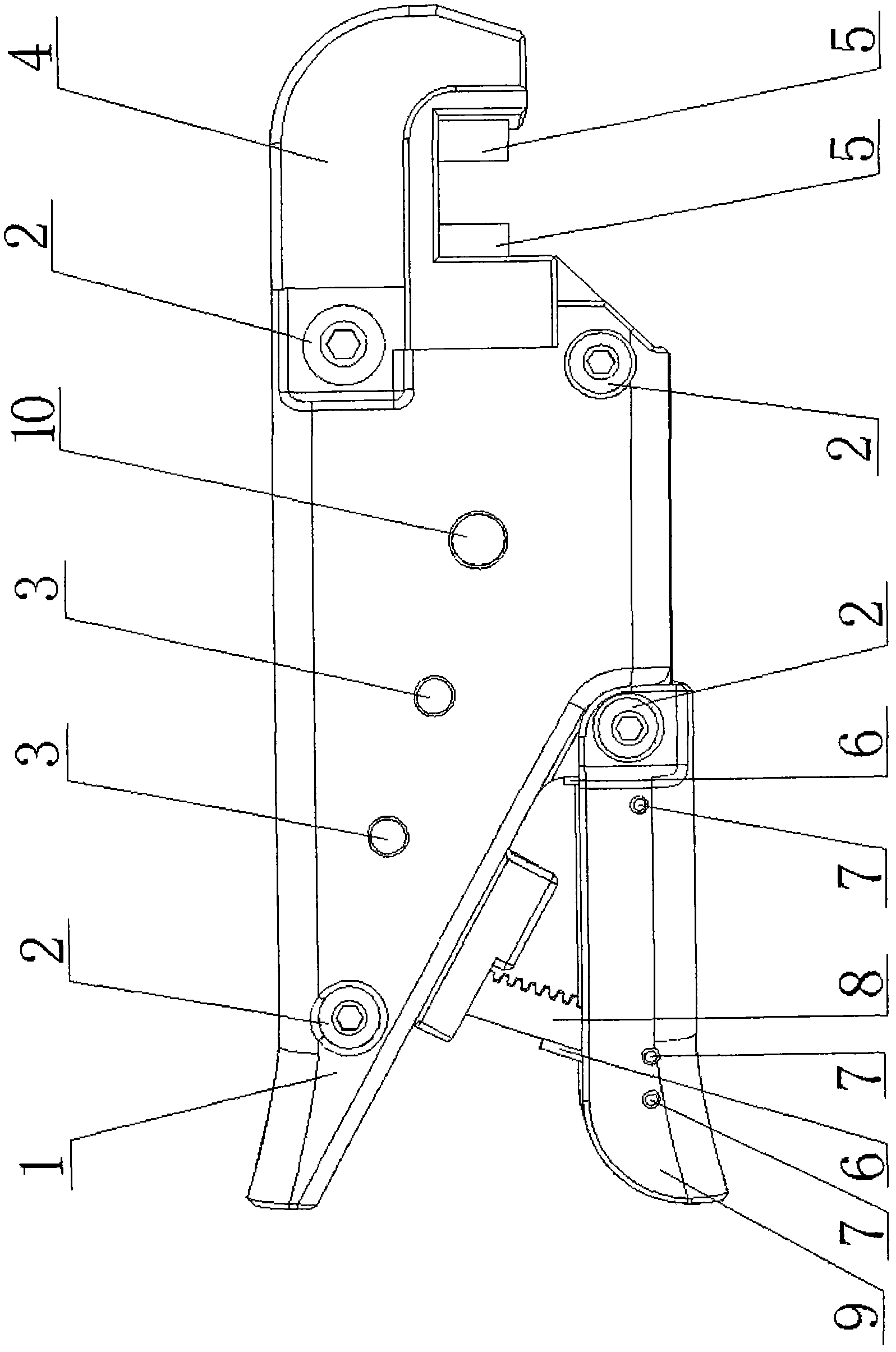

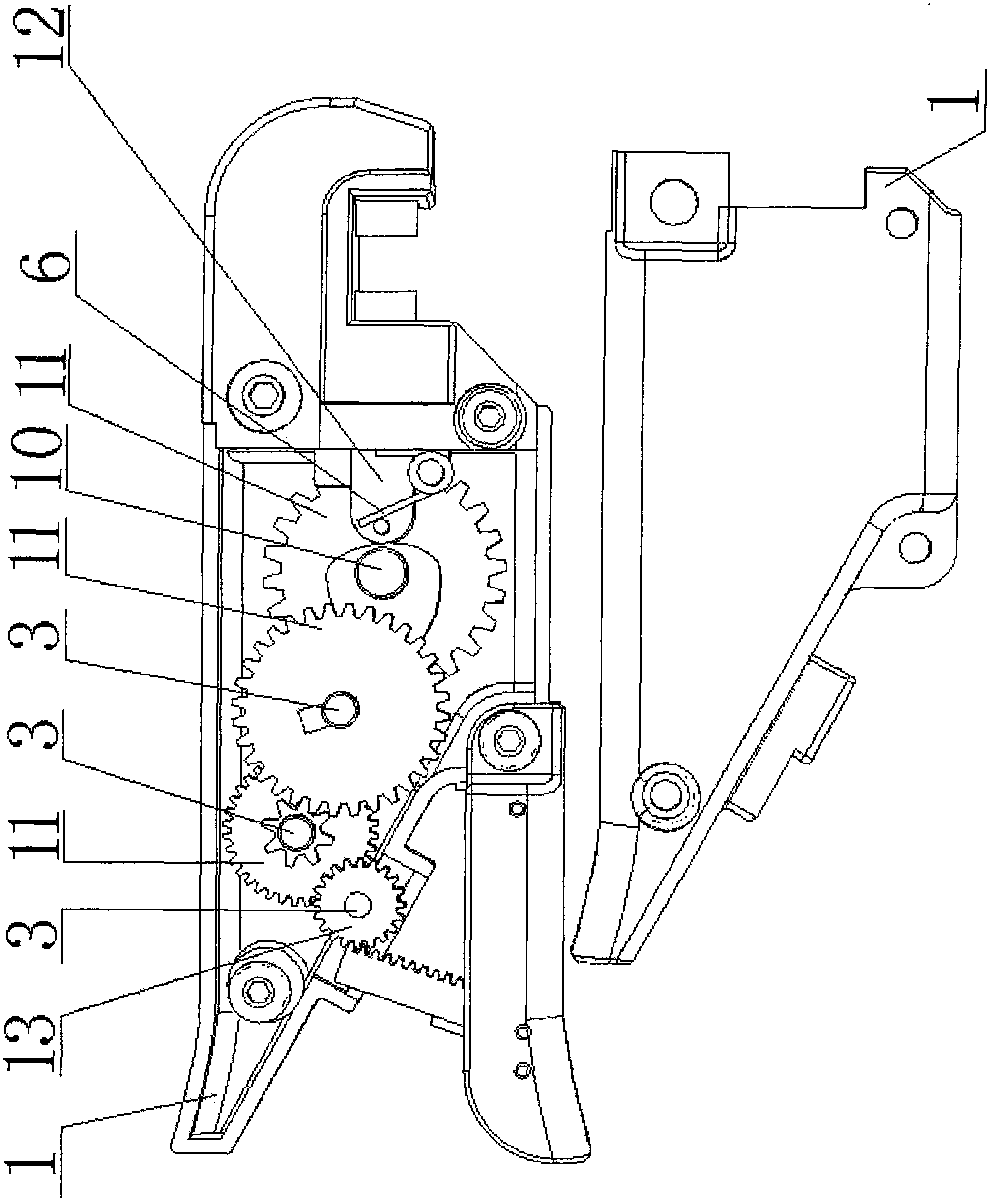

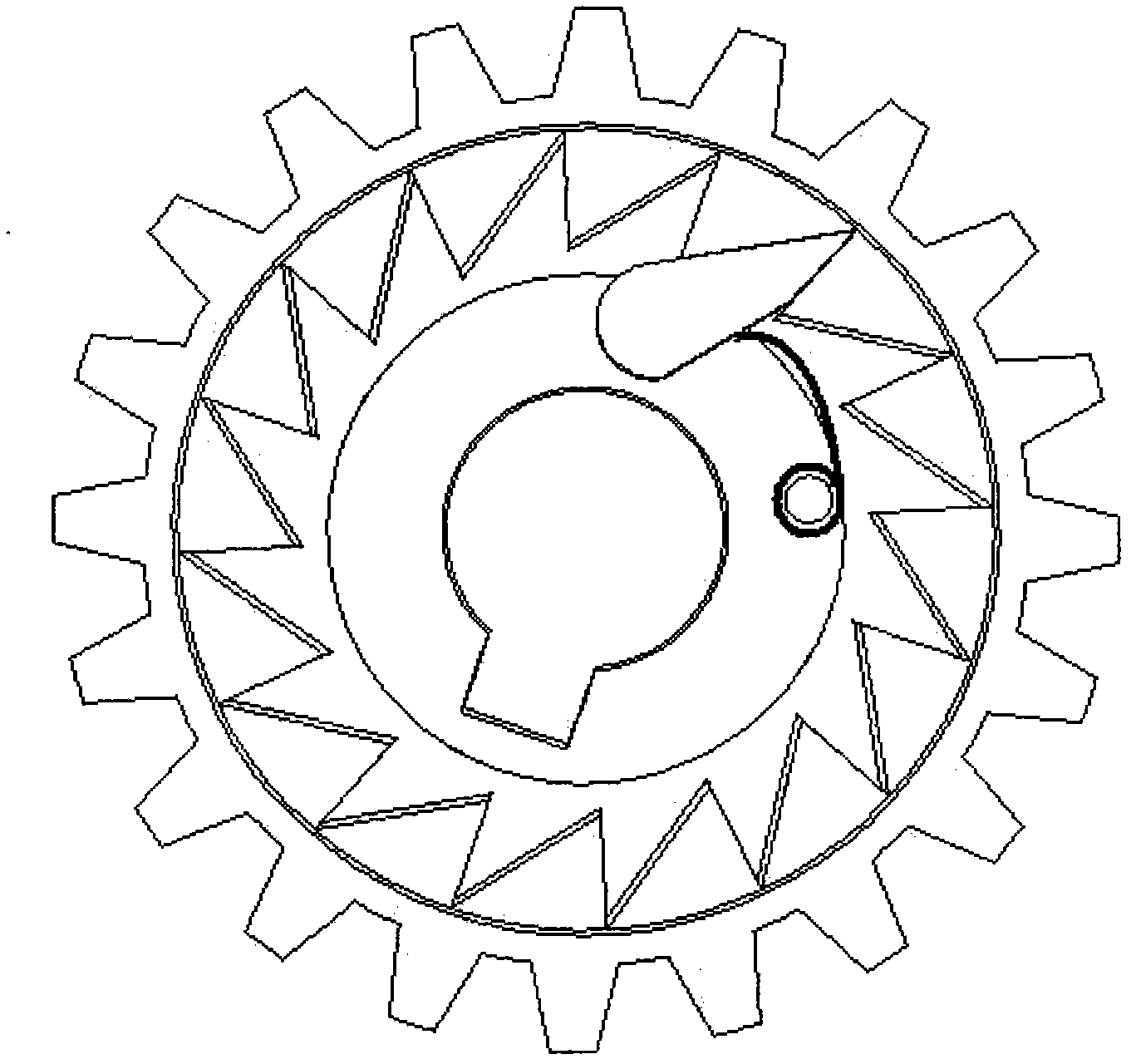

[0014] When the present invention is installed, the tool rest 4, the cutter head 5, the torsion spring 6 and the push rod 12 are installed first, and then the flywheel 13, the pinion shaft 3, the gear 11 and the camshaft 10 are respectively installed in the handle box 1 on one side, Close the handle box 1 on the other side, and then use the bolt 2 to connect and fix them. Gear bar 8 is installed in movable handle 9 with pin 7, torsion spring 6, puts one end of tooth bar 8 in the handle box and puts it away, and is connected on the handle box 1 with torsion spring 6 and bolt 2 again.

[0015] During work, hold the movable handle 9 to make the two cutter heads 5 reach a suitable distance, put the steel wire rod between the two cutter heads 5, and constantly hold the movable handle 9 so that the rack 8 drives the flywheel 13, the pinion 3. The gear set formed by the gear 11 rotates, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com