Preparation method of clearance-adjusting eccentric shaft for hot-rolled steel section flying shear cutting edge

A technology of eccentric shaft and flying shears, which is applied in the field of metallurgical hot rolling technology, and can solve problems such as difficult to achieve precise adjustment of the side clearance of the cutting edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

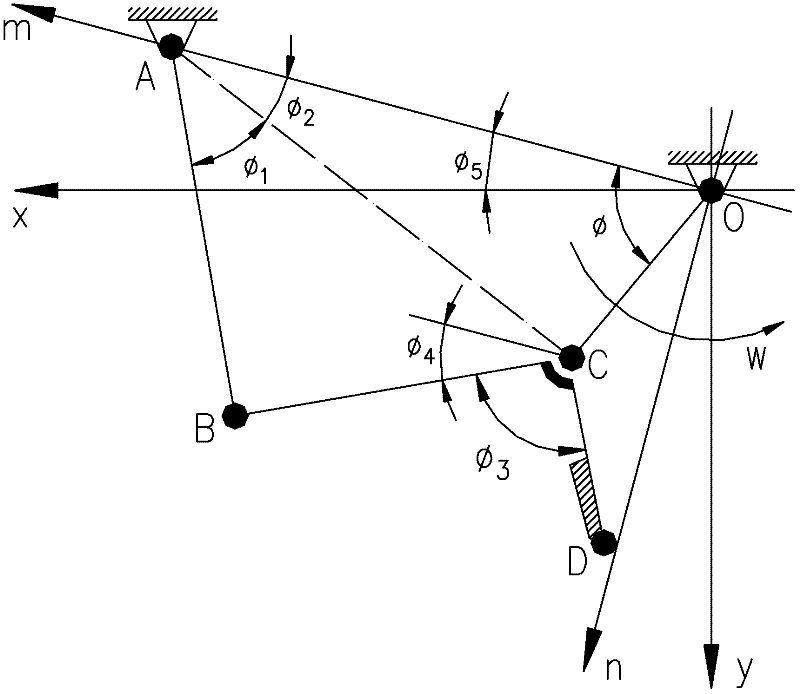

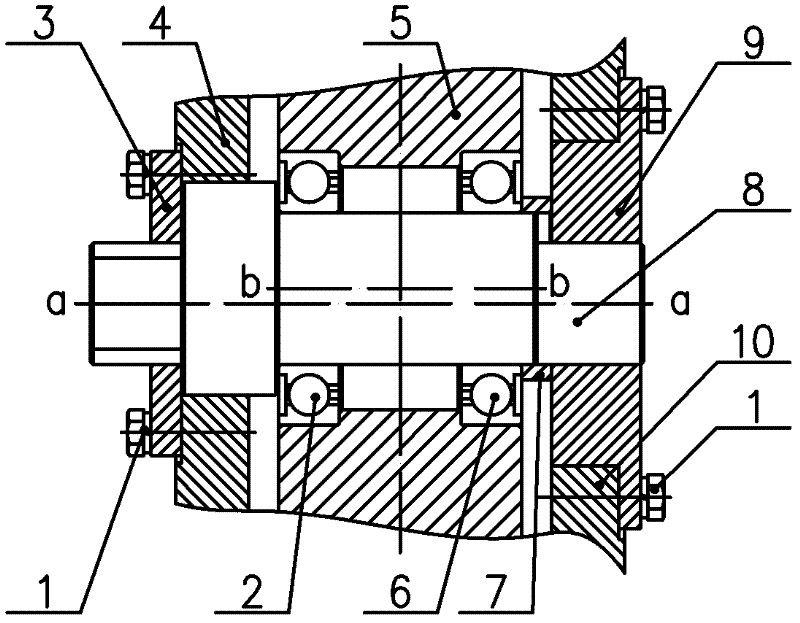

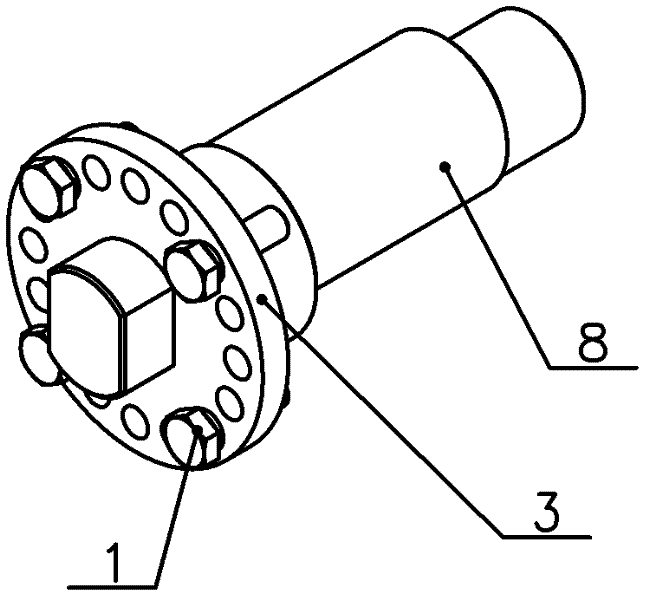

[0061] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0062] The preparation method of the hot-rolled section steel flying shear machine cutting edge gap adjustment eccentric shaft provided by the present invention includes the processing of the eccentric shaft 8 and the matching adjusting disc 3, connecting rod 5, connecting bracket and end cover 9, see figure 2 and image 3 ,specifically is:

[0063] (1) Adjust the processing of disc 3:

[0064] Holes are evenly opened around the disc body of the adjusting disc, and an arc-shaped long hole with both ends being arc-shaped and two sides being straight lines is opened in the middle of the disc body;

[0065] (2) Machining of eccentric shaft 8:

[0066] The eccentric shaft 8 is divided into four sections for processing, which are processed sequentially from left to right, wherein: the first section of the shaft body is the front end of the eccentric sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com