Hot-rolled steel section flying shear system speed reduction ratio control method

A system deceleration and control method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems affecting production capacity, affecting the cutting effect of flying shears, and the quality of section steel sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

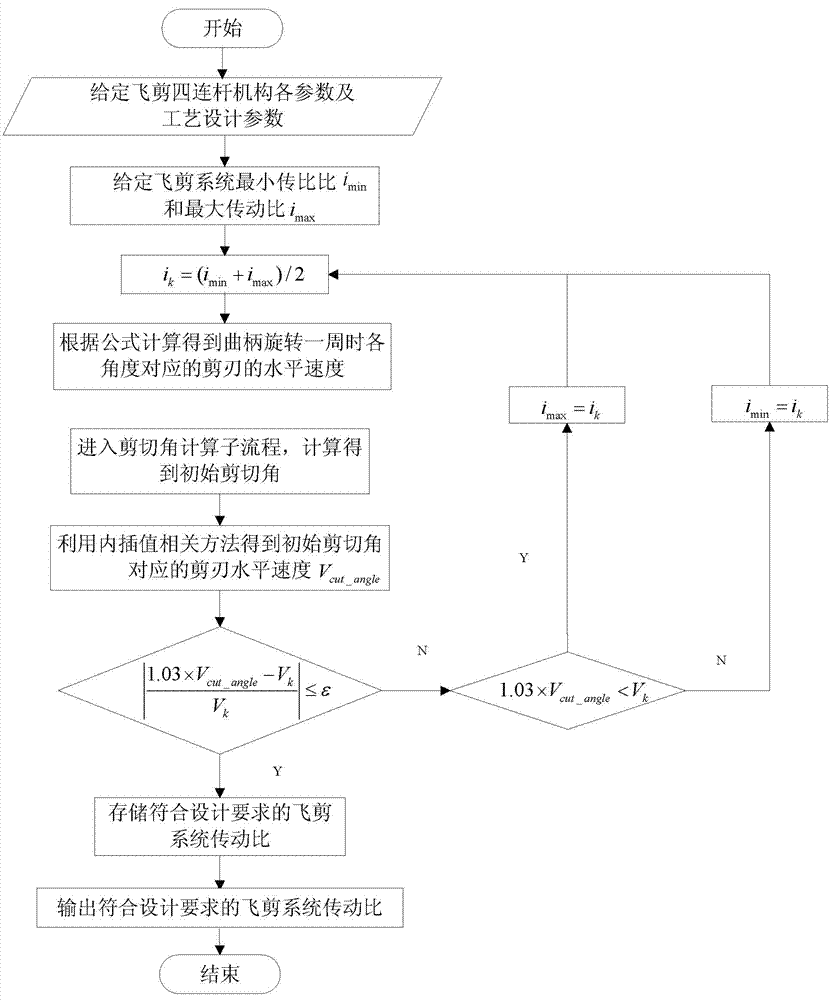

Method used

Image

Examples

Embodiment Construction

[0052] In order to facilitate a further understanding of the method of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

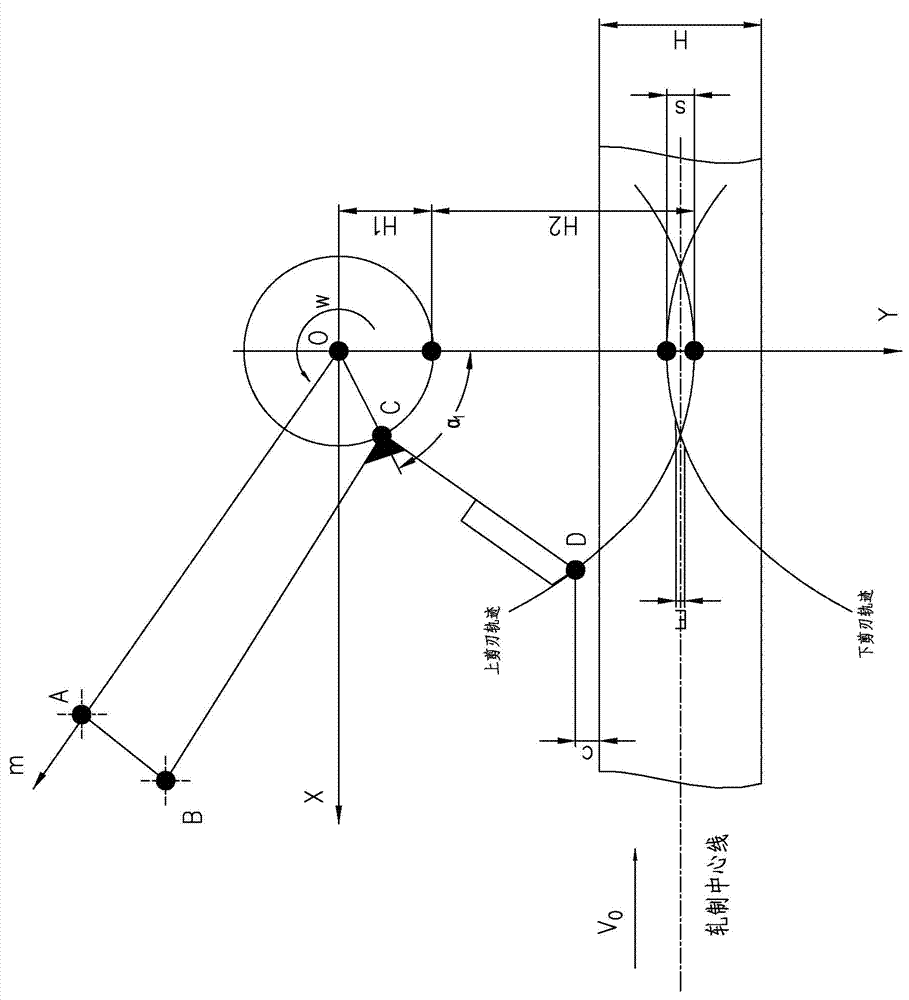

[0053] 1. The logical expression of the parameters required for the space trajectory and velocity calculation of the flying shears

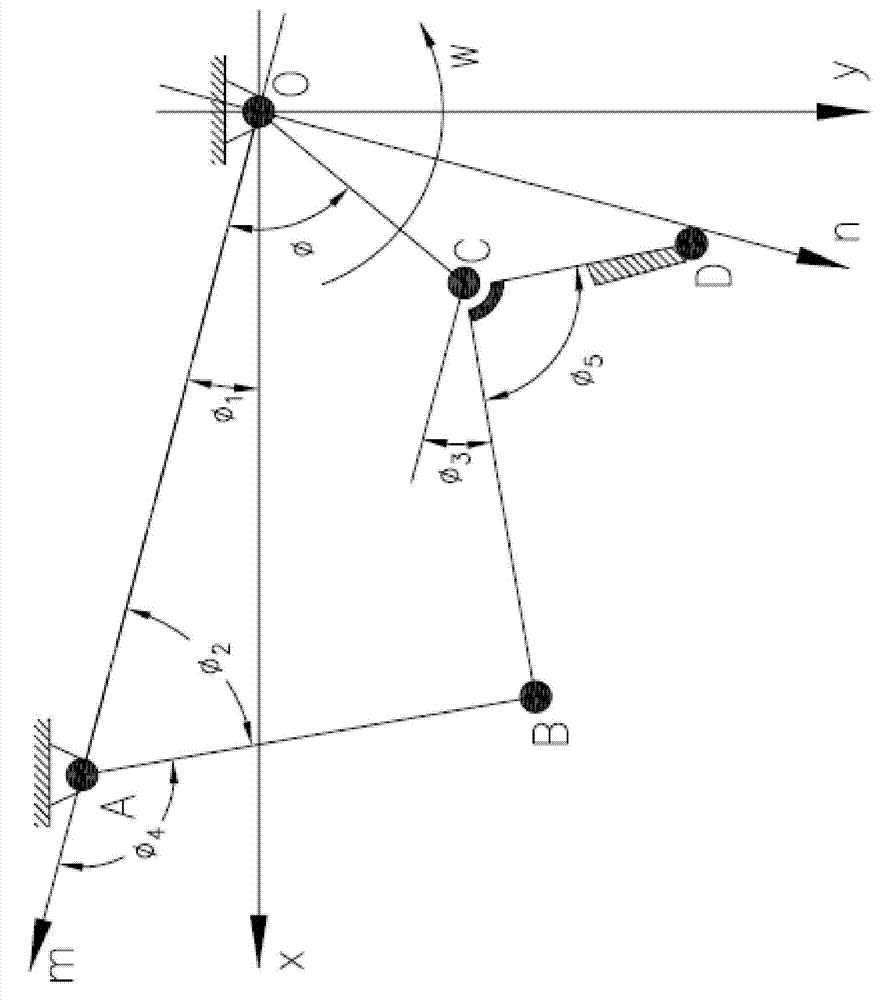

[0054] The original drawing of the upper cutting edge of the flying shears (the lower cutting edge is symmetrical to the rolling center line), as shown in figure 1 shown.

[0055] It is composed of crank OC, connecting rod AB and connecting rod BCD: wherein connecting rod BCD is welded by connecting rod BC and connecting rod CD, and the upper cutting edge is connected with connecting rod CD through a blade seat. The crank OC is driven by a motor to perform periodic rotary motion around its center of rotation O. It drives the connecting rod BCD and the upper cutting edge to move along the predetermined track through the hinge pair. One end B of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com