Process control method of maximum accelerating time of starting hotly-rolled type steel flying shear motor

A technology of acceleration time and motor start-up, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of section quality, difficulty, and difficulty that affect the shearing effect of flying shears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

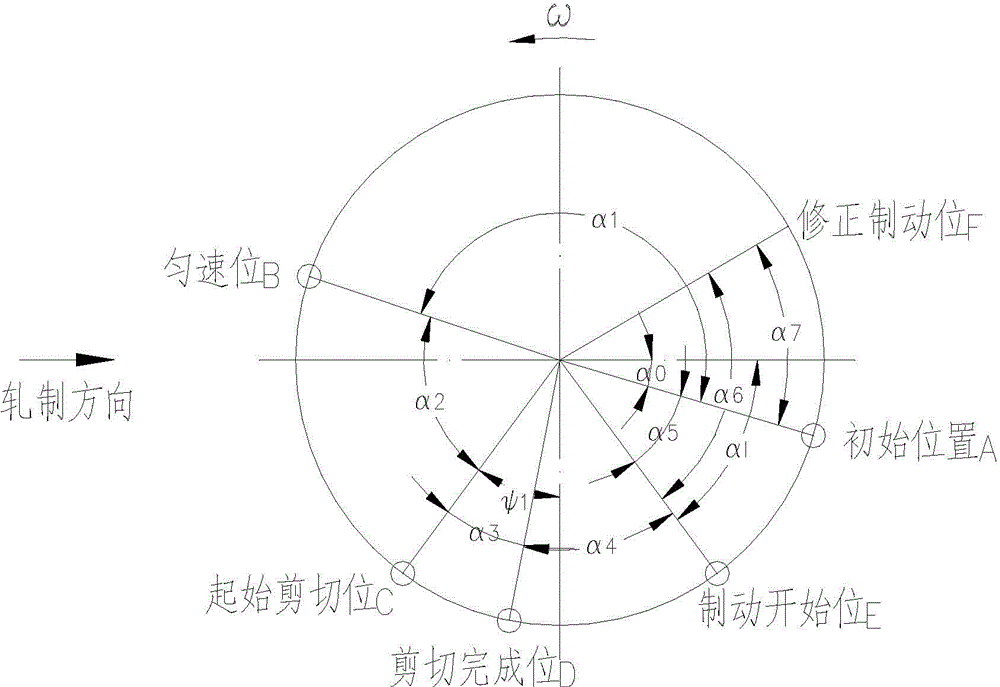

[0126] Embodiment 1: This embodiment provides a process control method for starting the maximum acceleration time of a hot-rolled section steel flying shear motor, which specifically includes the following steps:

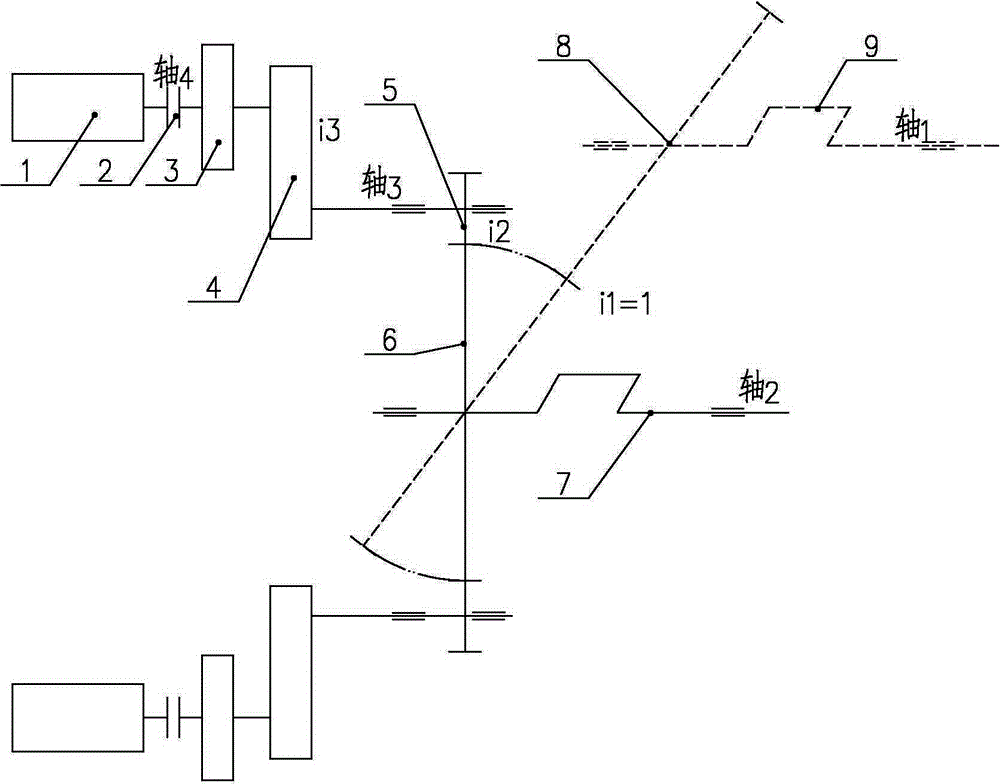

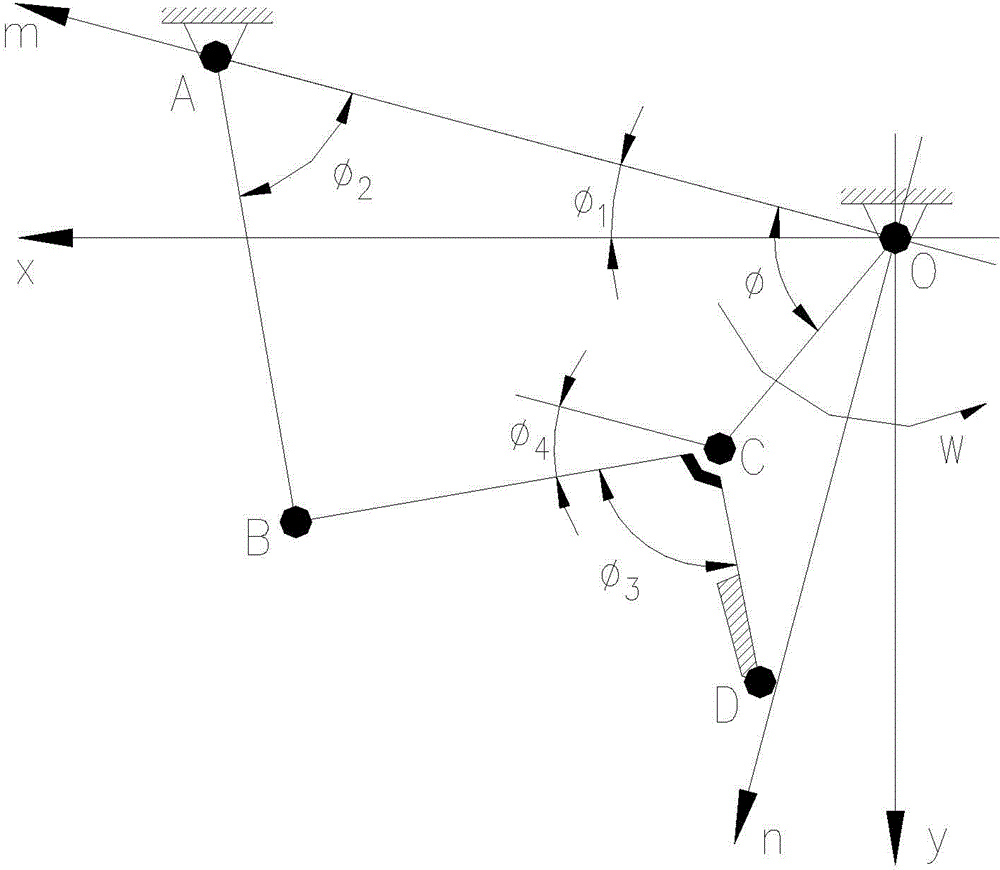

[0127] Step 1: As shown in Table 1, input the relevant parameters of each component of the hot-rolled flying shear mechanism: the length r of the fixed frame OA 1 , the length r of the rocker AB 4 , the length r of the connecting rod BC 3 , the length r of the connecting rod CD 5 , the length r of the crank OC 2 , Angle φ between connecting rod BC and connecting rod CD 3 , the angle φ between the xoy coordinate system and the mon coordinate system 1 , crank OC rotation angle φ, convergence tolerance ε 2 , Flying shear opening H o , the rated speed of the motor, the total transmission ratio of the system i, the coincidence degree of the cutting edge s, the relative height value of the unbroken section E, the horizontal speed of the sheared rolling piece V k , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com