Preparation method of upper tool post of cold-rolled flying shear

A tool holder and tool holder technology, which is applied in the field of shearing edge compensation, can solve the problems of unfavorable development of a cold-rolled flying shear control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

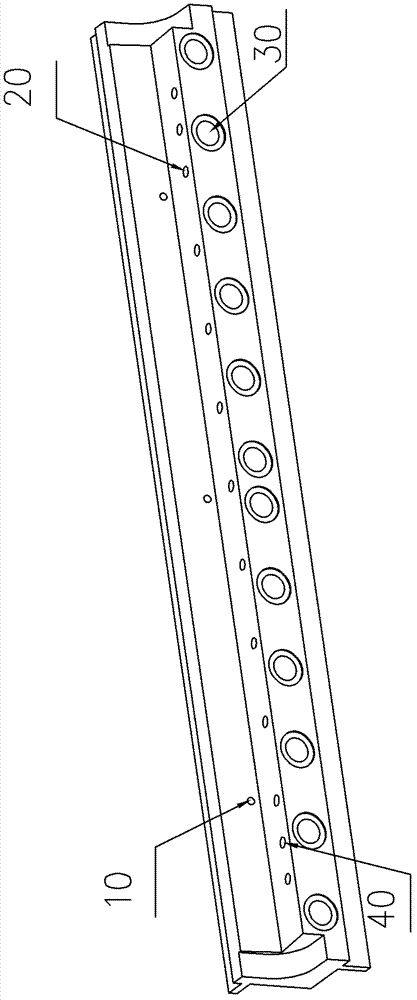

[0039] In order to facilitate a further understanding of the method of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

[0040] The design principle of the cutting edge compensation in the present invention is as follows:

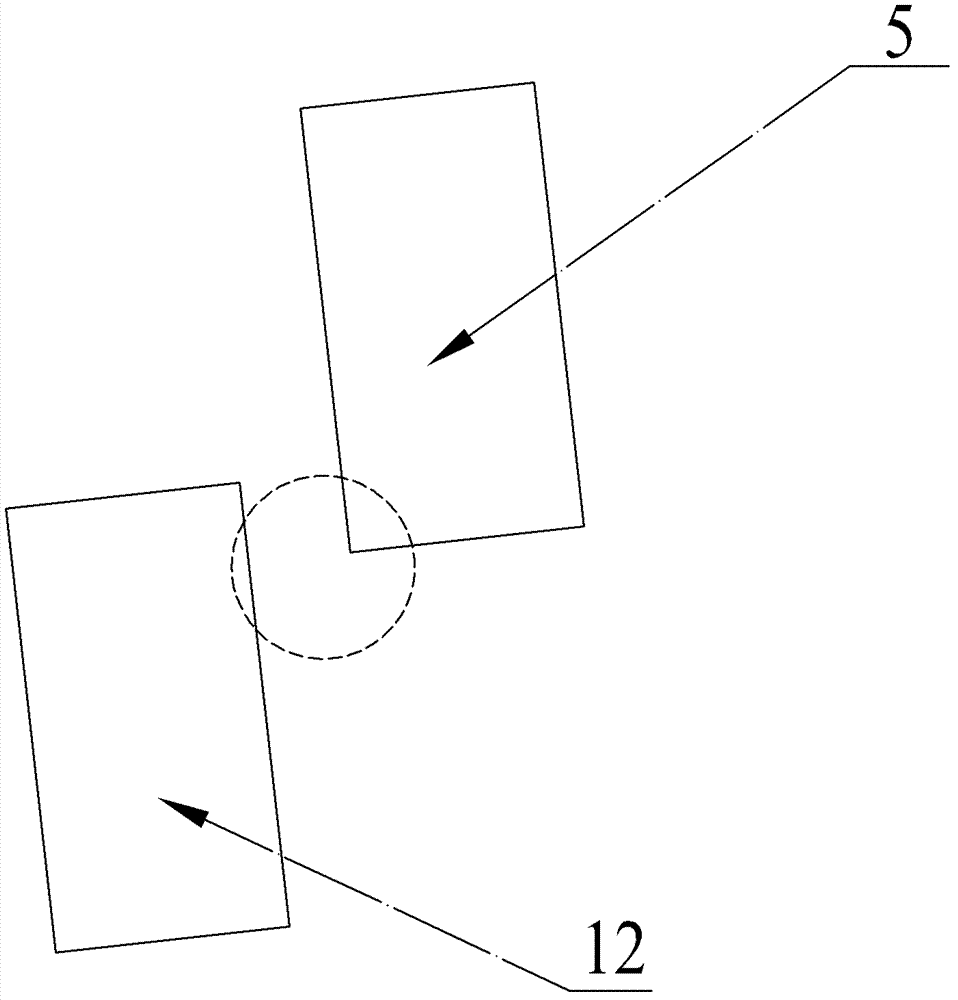

[0041] (1) Logical expression of the spatial trajectory of the upper and lower cutting edges of flying shears

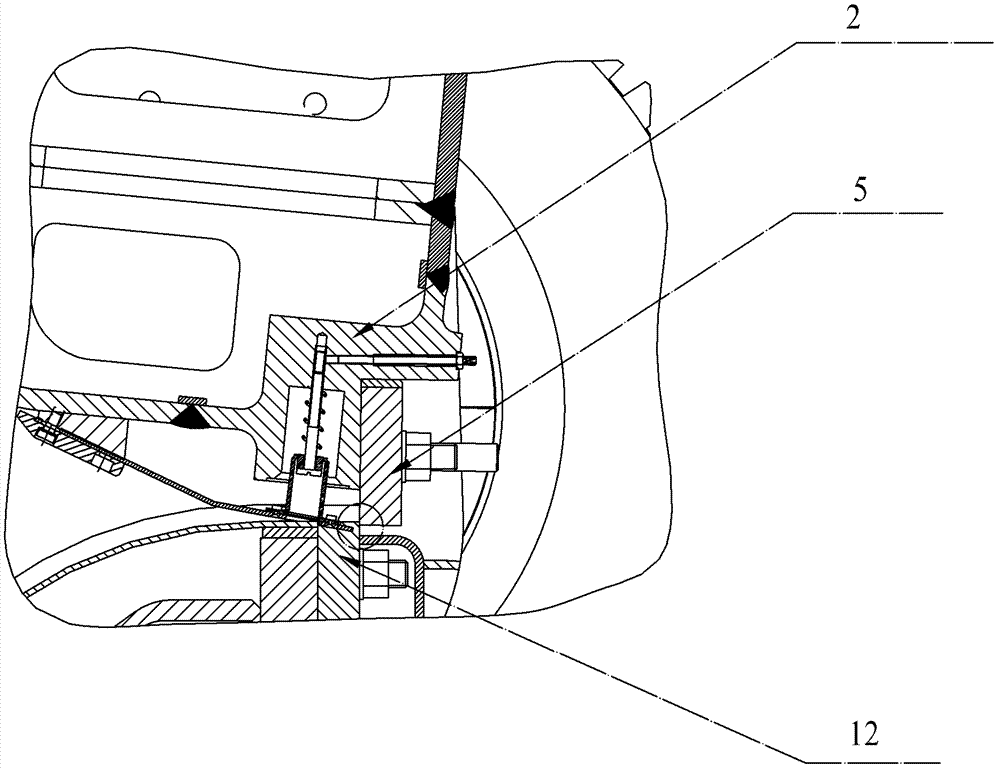

[0042] Schematic diagram of flying shear movement mechanism Figure 5 shown. The trajectory of the shear blade can be solved through vector equations and geometric relations. details as follows:

[0043] In the coordinate system mon, apply the relevant knowledge of the vector equation to the quadrilateral OABC:

[0044] OA · cos ( θ 1 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com