Capping head of high-speed moving cover

A high-speed movement and capping technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of fast and low-loss assembly that cannot be applied to moving caps, and achieves to improve assembly speed and yield, increase protection, and grasp Cover smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

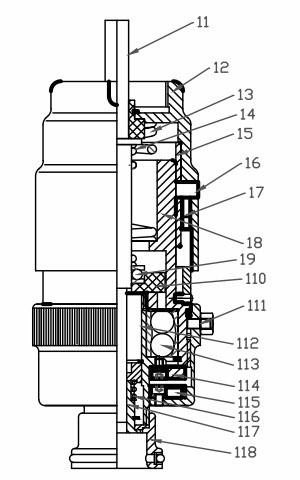

[0023] In order to solve the problem that the capping head in the prior art is not suitable for the installation of the moving cap, the technical solution adopted in the present invention is: the ejector rod is connected with the ejector rod connecting body by thread, and then the axial force is transmitted through the thrust bearing and the capping head. There is a sleeve between the shaft and the push rod, which can slide relatively. Two radial bearings of different sizes are housed in the fixed shaft, the fixed shaft cooperates with the outer ring of the radial bearing, the rotating shaft is contained in the inner ring of the radial bearing, and the rotating shaft cooperates with the inner ring of the radial bearing. The inner magnetic ring is connected to the rotating shaft through the inner magnetic ring carrier, and the outer magnetic ring is connected to the fixed shaft through the outer magnetic ring carrier. During the capping process, the capping torque is smaller tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com