Plunger assembly rolling and loosening fixture and use method thereof

A component and plunger technology, which is applied in the field of rolling tooling of the plunger component, can solve the difficulty of the rolling process, the inability of the sliding shoe and the plunger body to rotate flexibly, the flexibility and the axial clearance not meeting the requirements of the parts, etc. problems, to achieve the effect of optimizing the structure of rolling loosening tooling and high rolling loosening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

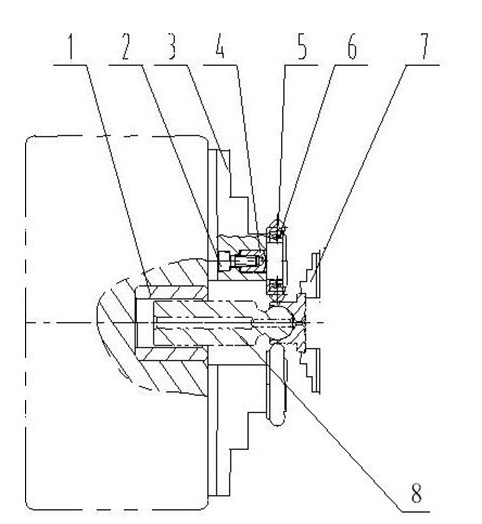

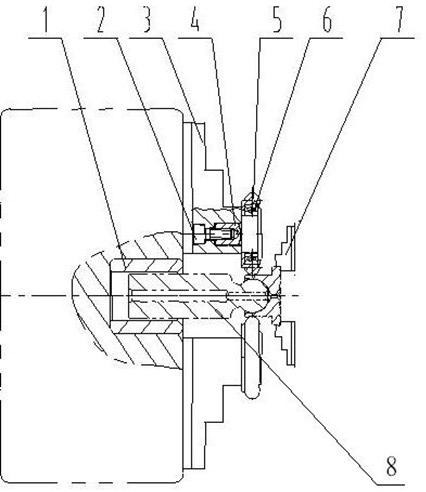

[0017] Attached below figure 1 Further description is given to specific embodiments of the present invention.

[0018] A plunger assembly rolling tool for lathes, including nylon guide sleeves, bolts, rolling chucks, connecting shafts, rollers, bearings and main clamping chucks; the rollers are basically ring-shaped and made of soft metal materials For example, low-carbon steel, the rolling surface is preferably a convex surface, and a groove is provided on the annular inner wall, and the outer ring of the bearing is pressed into the groove of the roller; the rolling chuck includes rolling claws, and the rolling chuck The claw is movably set on the base of the rolling chuck, and it can move along the radial direction of the rolling chuck, that is, change its position in the center of the rolling chuck; the connecting shaft acts as a connection, and one end is connected to the inner hole of the bearing It is connected in the way of interference fit, and the other end is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com