Asphalt mixture mixed ratio design method based on shearing resistance performance

A technology for design of asphalt mixture and mix ratio, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problem of not being able to effectively control the shear stress of asphalt layers, evaluate the shear performance of asphalt mixture, and have no system problems using mechanics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Example: Design the mix ratio of asphalt mixture for the middle surface layer of a highway:

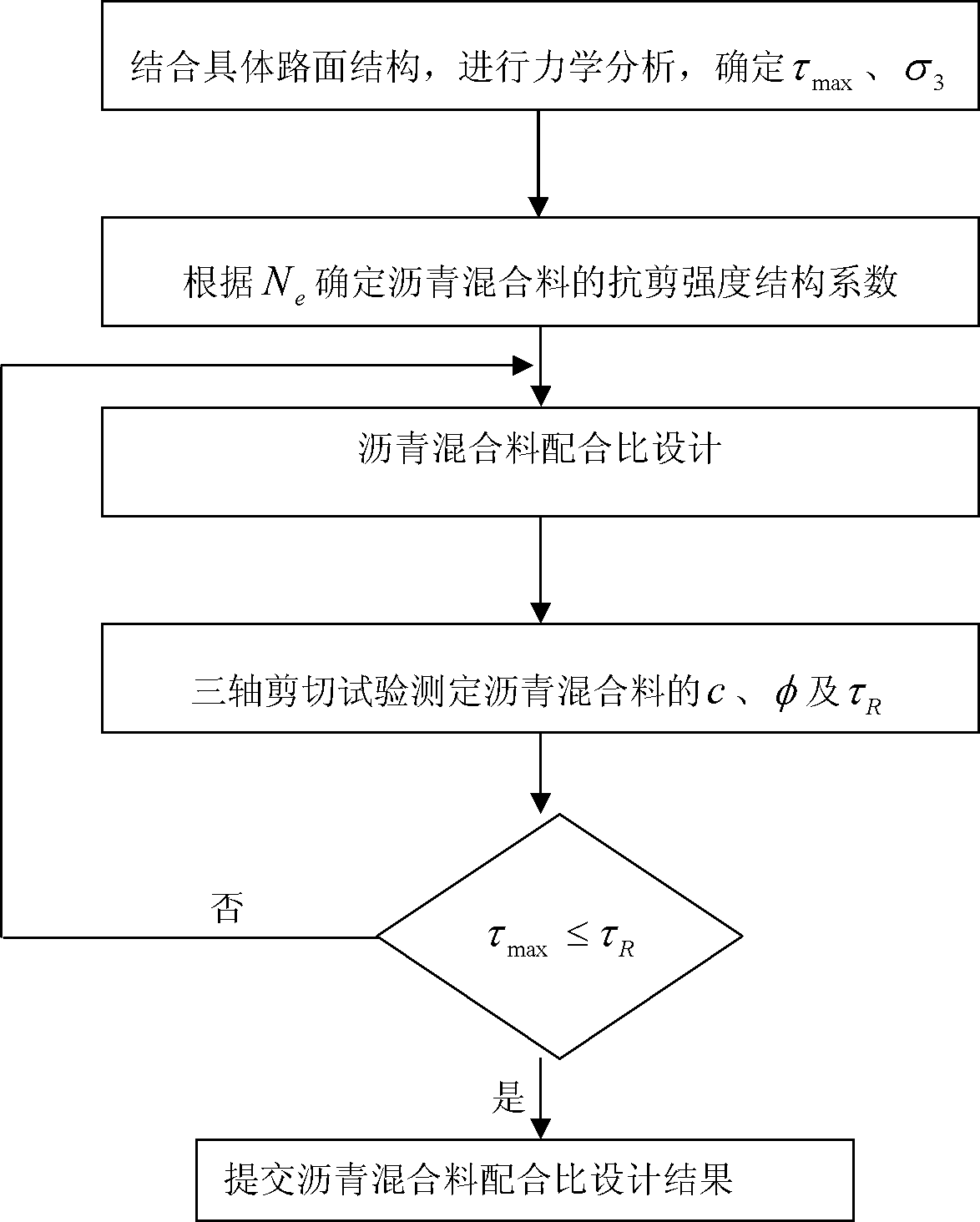

[0029]Mix ratio design method of asphalt mixture based on shear resistance (see figure 1 ), which is characterized in that it comprises the following steps:

[0030] (1) The pavement structure of the expressway is shown in the table below. The cumulative number of axle loads within the design life is 22.56 million times / lane, and the design axle load is 100KN.

[0031] Pavement structure form and material parameter value

[0032]

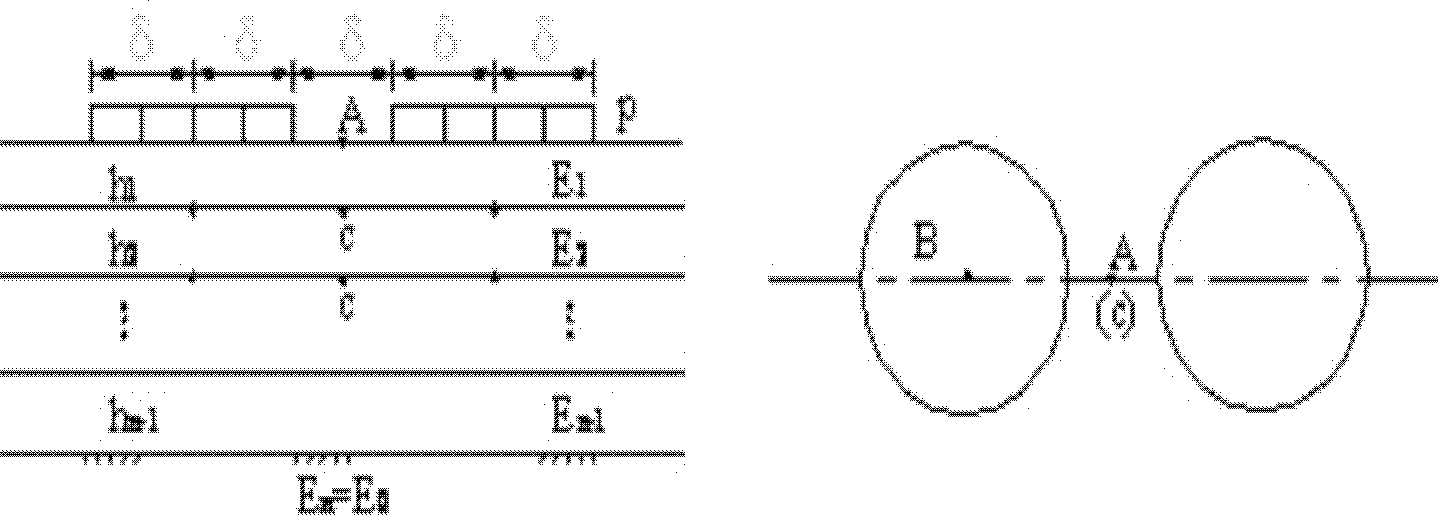

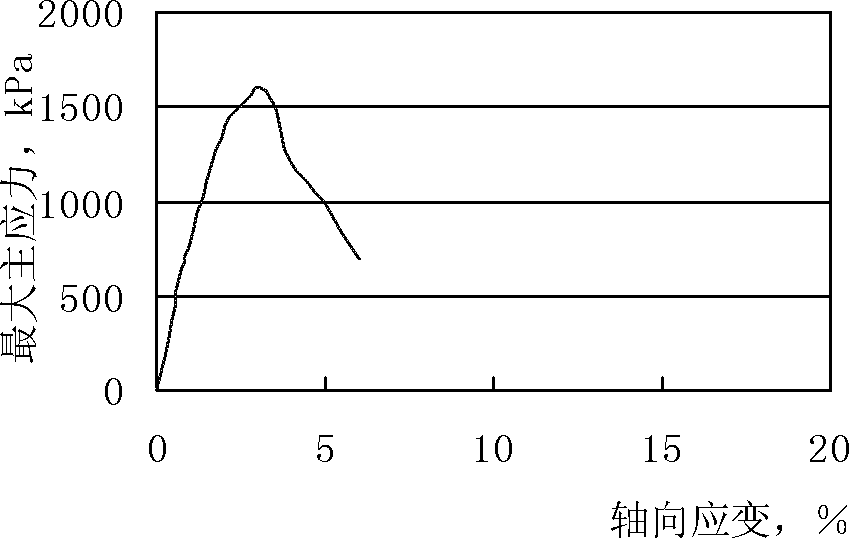

[0033] (2) Determine the maximum shear stress of the structural layer where the designed asphalt mixture is located, and obtain the maximum shear stress τ of the pavement through the mechanical analysis of the pavement structure max : Determine the design parameters of the pavement structure. The pavement structure is proposed to be in a semi-infinite space elastic state, and the layers of each structure are in a continuous state. The elastic l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com