Dual-station yarn feeding device

A dual-station, yarn feeding technology, applied in textiles, textiles, papermaking, looms, etc., can solve problems such as troublesome processes and affect production efficiency, and achieve the effect of improving work efficiency and solving singleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, and the protection scope of the present invention can be more clearly defined.

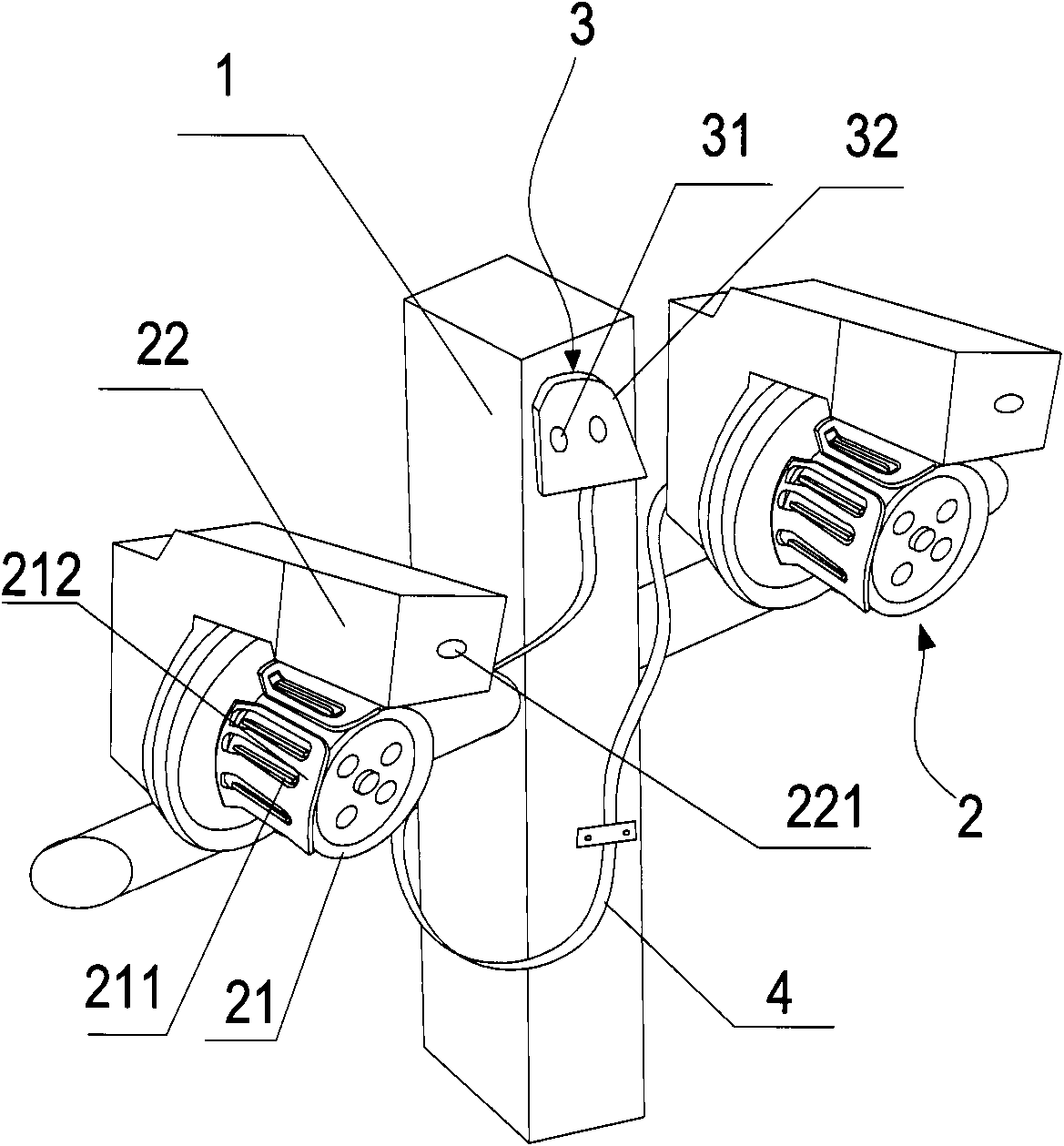

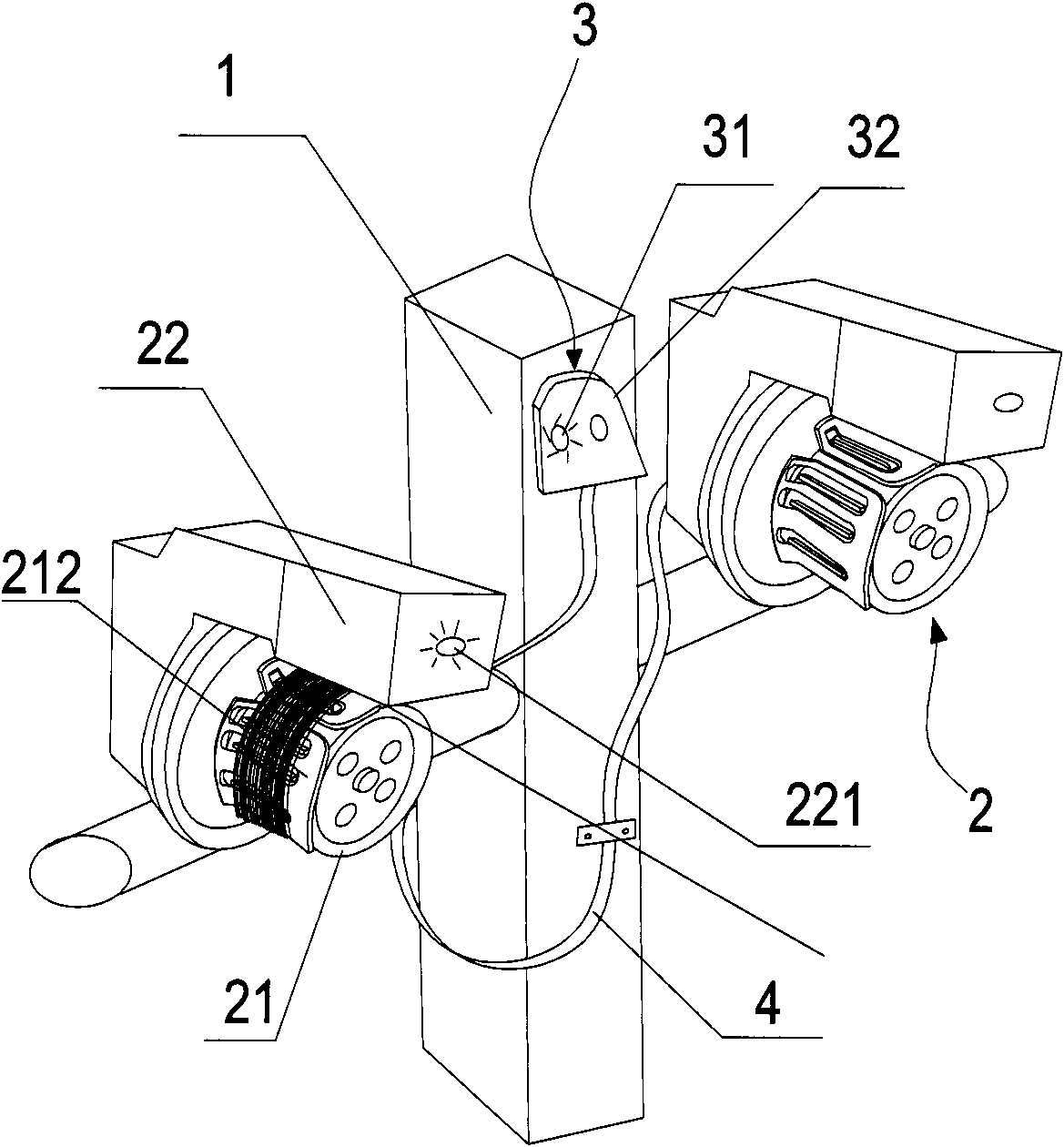

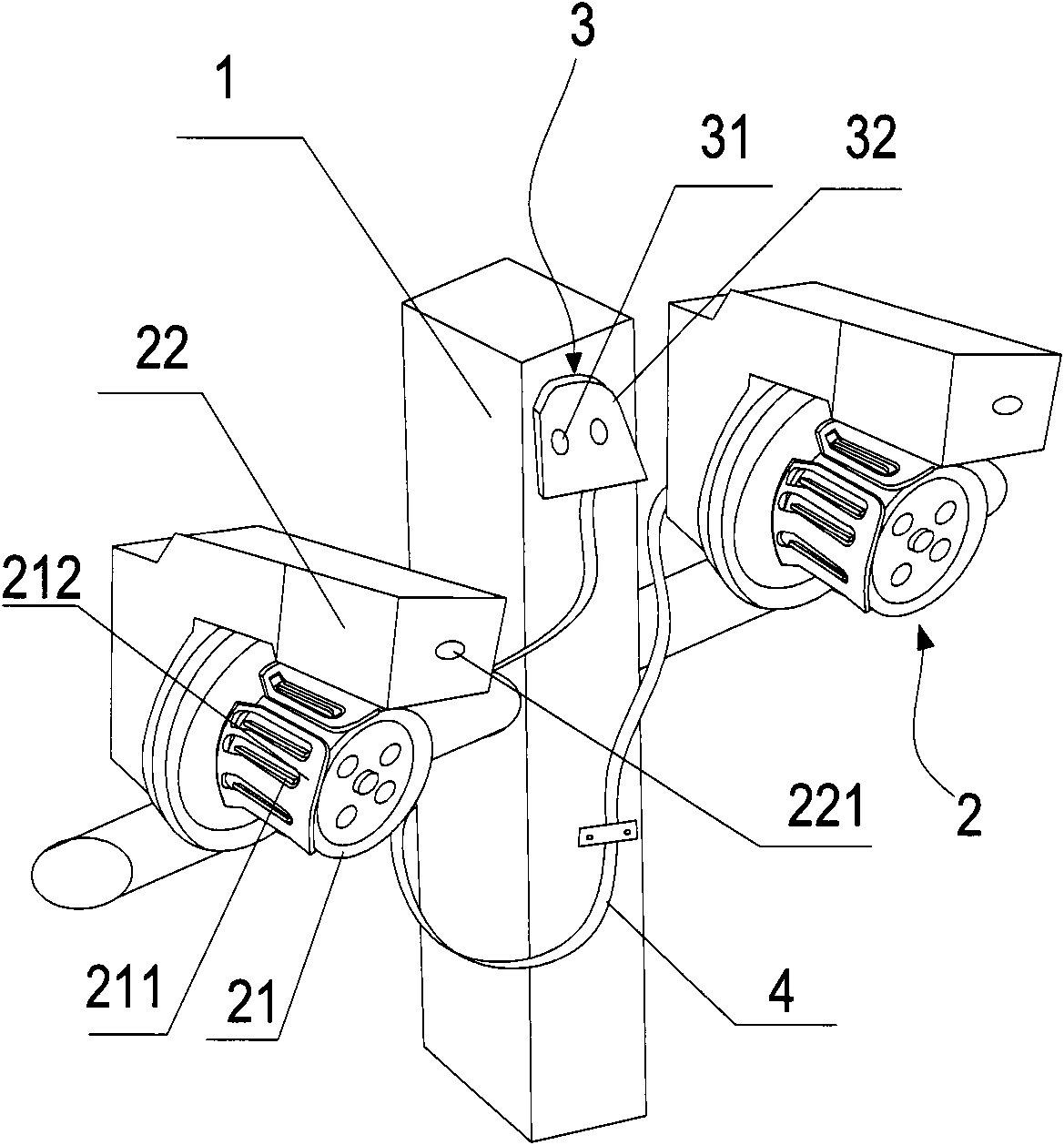

[0016] as attached figure 1 , attached figure 2 As shown, the present invention provides a double-station yarn feeding device, which includes a spinneret 1, a spinneret 2 fixed on both ends of the spinneret 1, and a top end fixed on the spinneret 1 and connected to the spinneret 1. The controller 3 that the component 2 is turned on, the spinning component 2 is composed of a main body 21 and an inductor 22 arranged on the upper end of the main body 21. The controller 3 is provided with a control circuit inside. When the control circuit outputs an induction signal to the spinning component 2 , the spinning part 2 performs alternate spinning.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com