Spiral-flow type dilution mixer with adjustable blades for gas drainage

A blade swirl and gas extraction technology, which is applied in the field of ultra-low concentration methane thermal countercurrent oxidation and low-density energy recovery, can solve the problems of large flow resistance, increased energy consumption of transport gas, complex structure, etc., and avoid friction explosion. , The effect of reducing transmission power consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

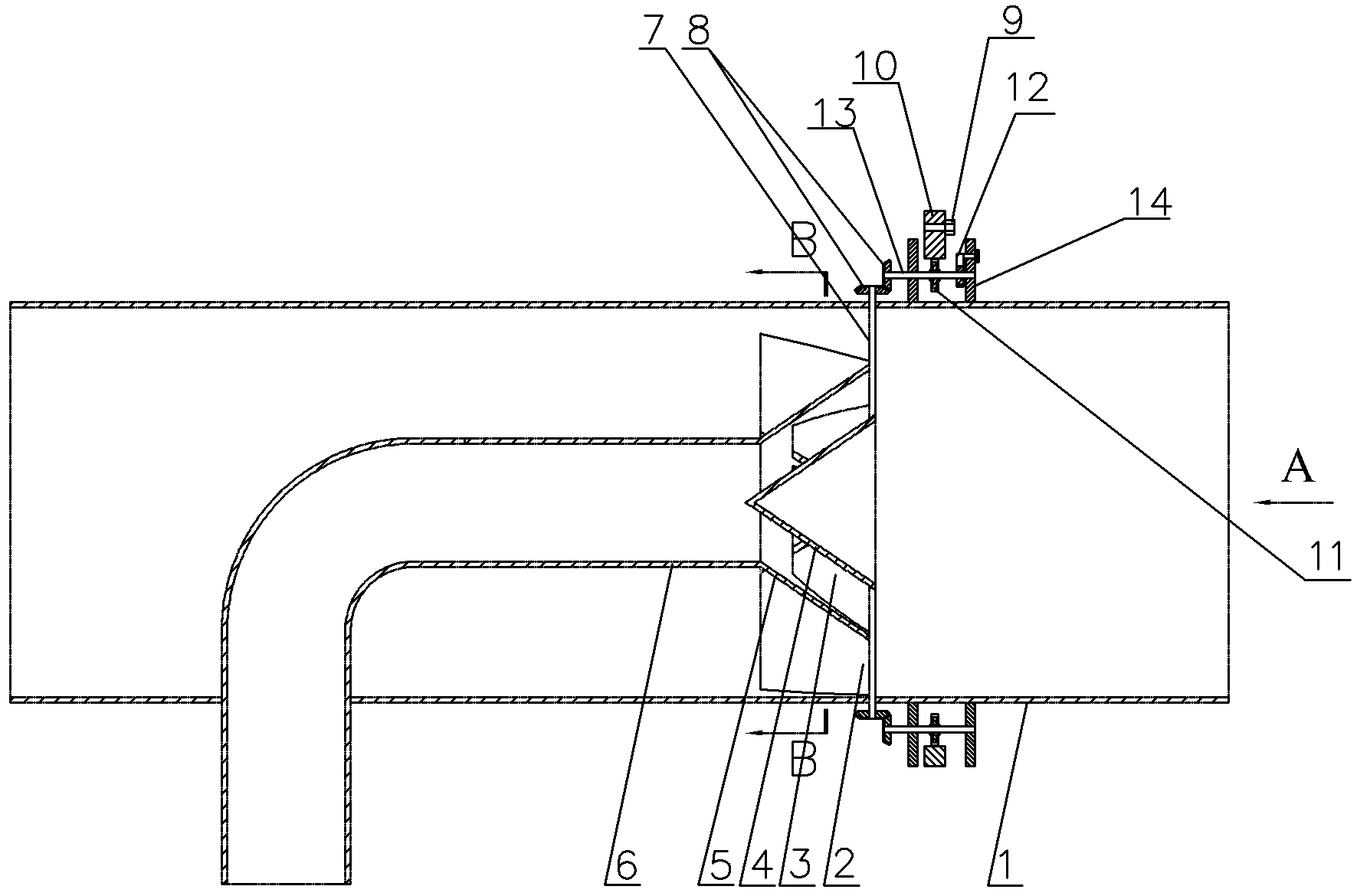

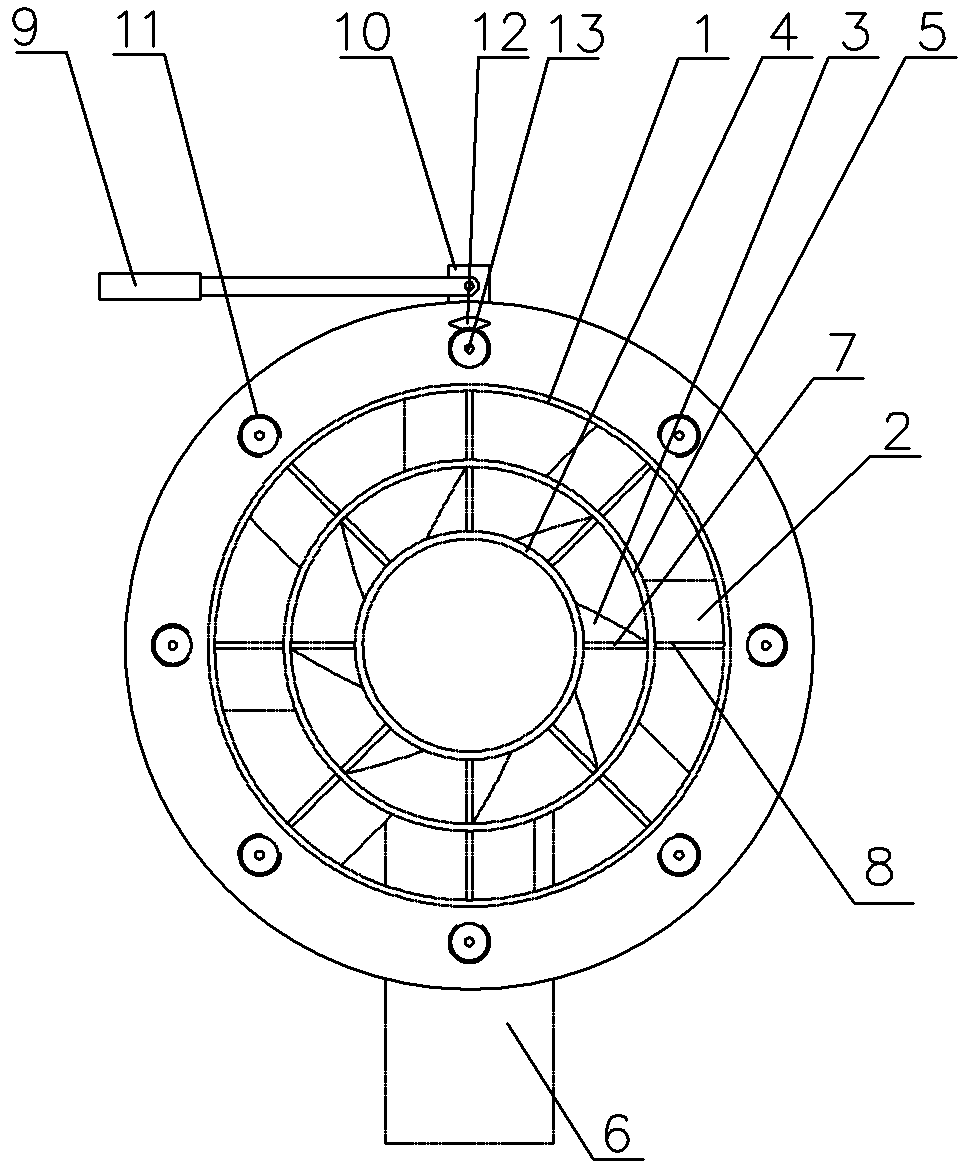

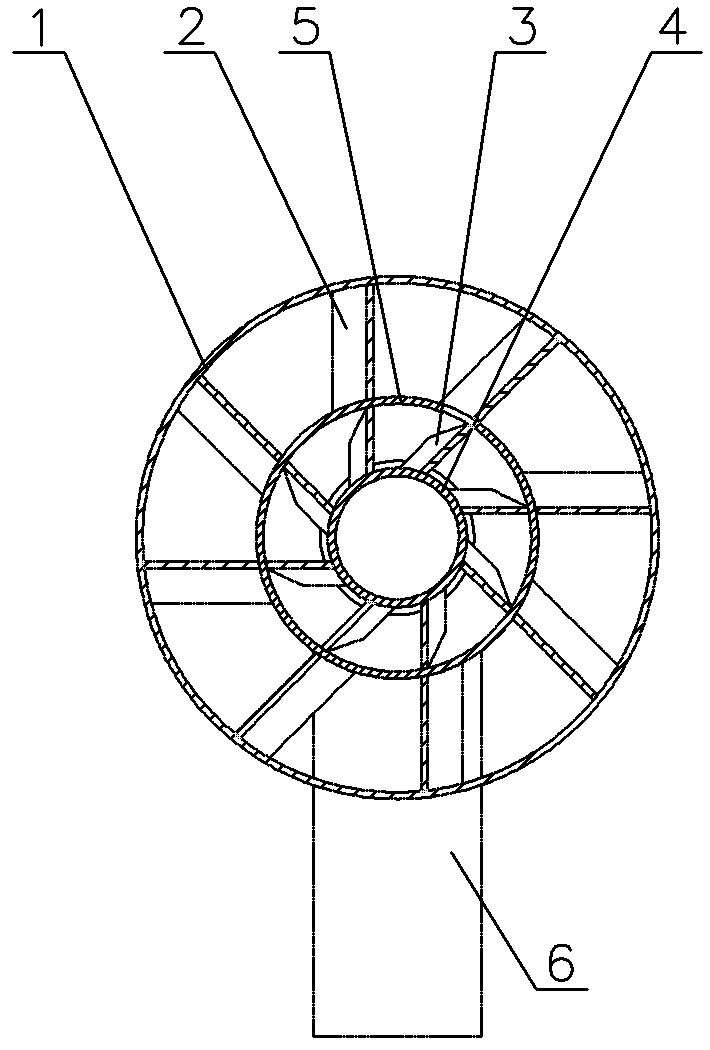

[0021] exist Figure 1-3 In the shown embodiment: it includes a tubular casing 1, a gas injection pipe, a guide cone 4, an inner deflection blade 3, an outer deflection blade 2, a blade adjustment mechanism and a bracket 14, and the gas injection pipe includes an inlet pipe 6 and The expansion tube 5 installed on the outlet end of the inlet pipe 6, wherein the inlet pipe 6 is a 90 ° elbow, the inlet end is arranged outside the housing 1, the straight pipe section of the inlet pipe 6 near the inlet end penetrates into the housing 1 vertically, and the straight pipe section near the outlet end The pipe section is horizontally arranged in the housing 1, connected with the expansion tube 5 and facing the outlet end of the housing 1; wherein the diversion cone 4 is located in the expansion tube 5, which is a cone structure, and its tip faces away from the outlet end of the expansion tube 5 The axis of the straight pipe section near the outlet end of the inlet pipe 6, the expansion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com