Water jet nozzle for solar water heating system

A technology of solar hot water and water jet, which is applied in the direction of solar thermal power generation, solar thermal devices, injection devices, etc., can solve the problems of poor water discharge and uneven water mixing, and achieve the effect of small pipe resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

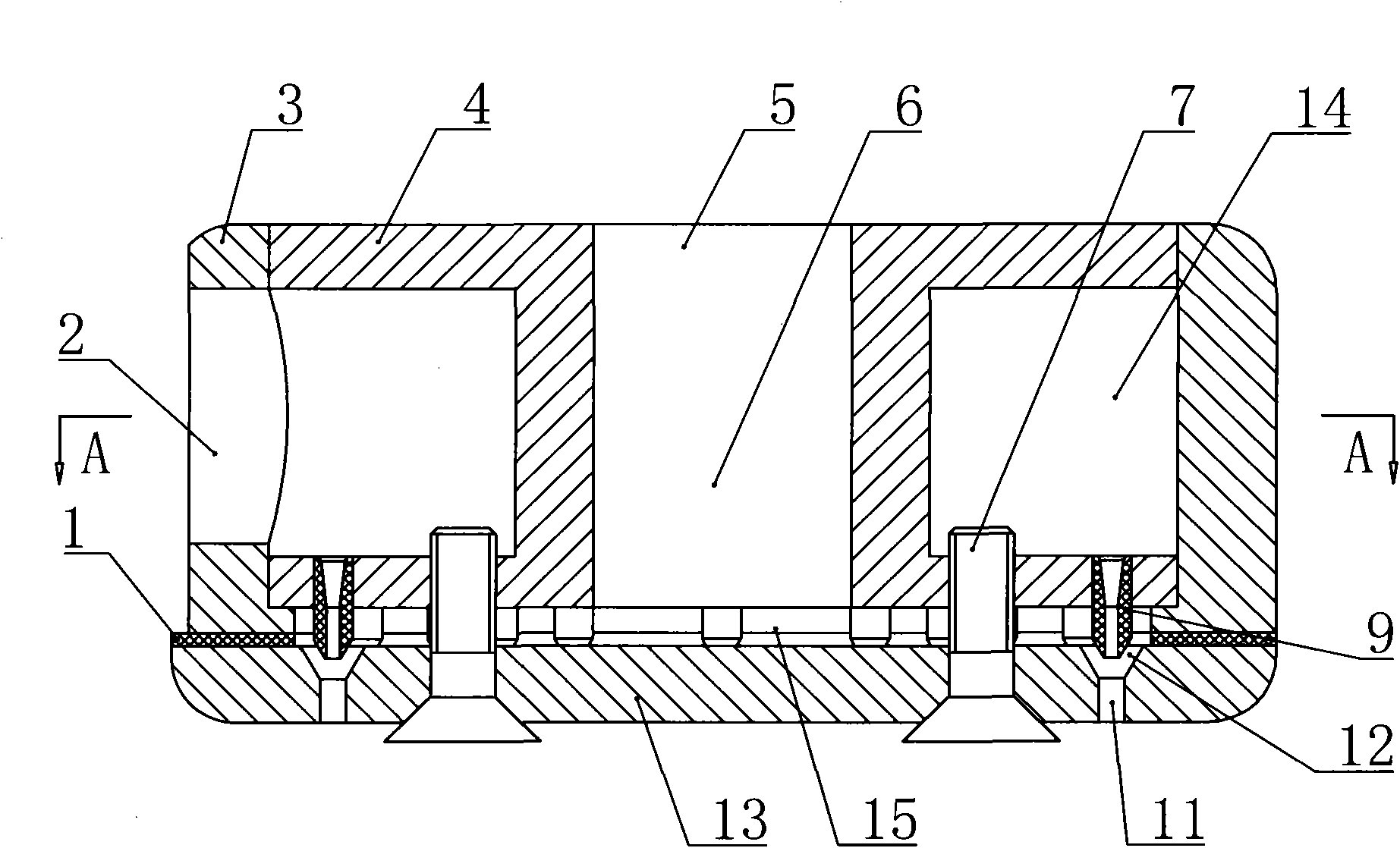

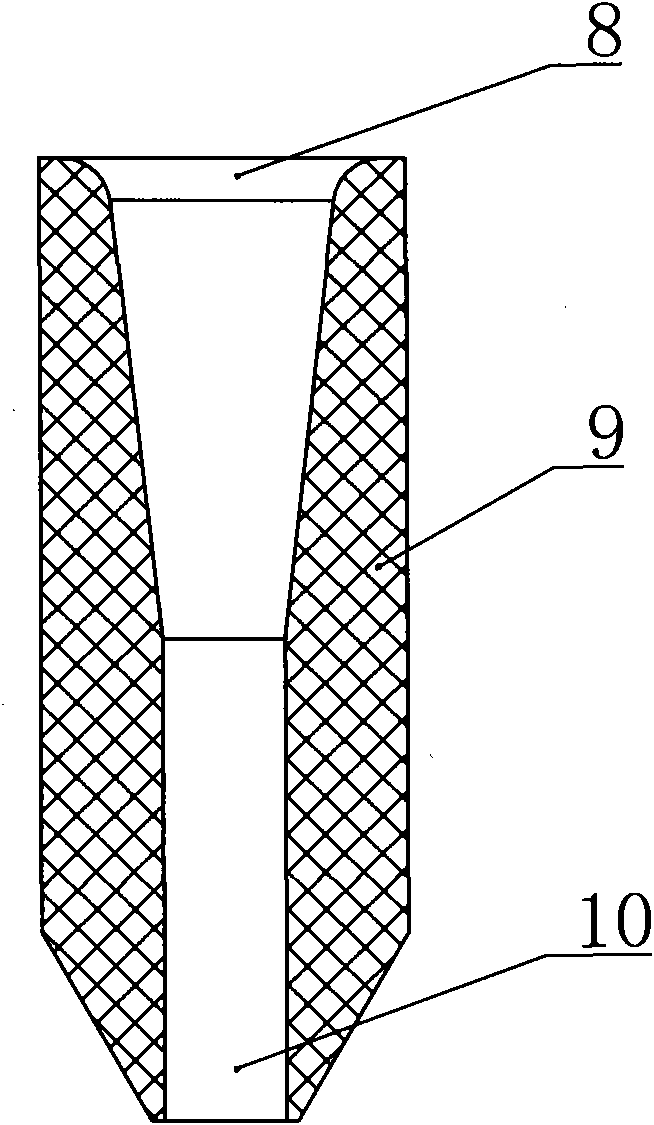

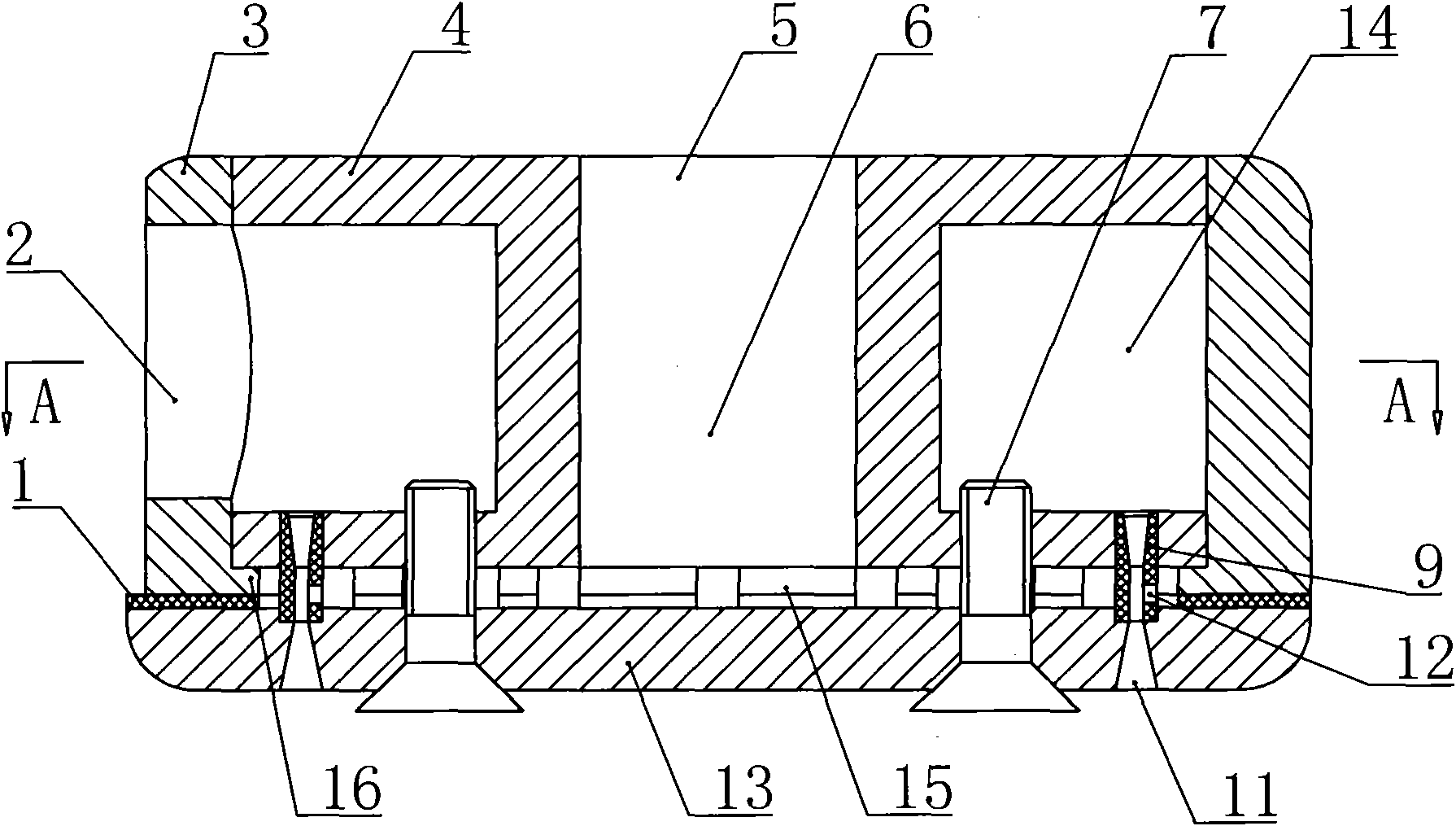

[0032] See Figure 1 ~ Figure 7 , The present invention includes an outer sleeve 3, an inner sleeve 4 and a base 13. The bottom end of the annular outer sleeve 3 and the upper edge of the base 13 are sealed by a sealing ring 1. A cold water inlet 2 is provided on one side of the annular outer sleeve 3. The inner sleeve 4 is embedded in the outer sleeve 3; an annular groove and a hot water cavity 6 are respectively provided on the periphery and the axis of the inner sleeve 4, and a hot water inlet 5 is provided at the upper end of the hot water cavity 6, and the annular groove and The inner peripheral surface of the annular outer sleeve 3 constitutes an annular cold water channel 14. The inner sleeve 4 and the base 13 are provided with a plurality of jets that penetrate the cold water channel 14 and the lower surface of the base 13, and the inner sleeve 4 A hot water gap 15 is provided between the bottom end of the jet and the base 13, and a jet hot water inlet 12 communicating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com